Vol. 34 Nos. 1-2 Dec. 1972

THE MISSOURI ARCHAEOLOGIST

VOLUME 34, NOS. 1-2 COLUMBIA, MO. DECEMBER, 1972

Editor: Robert T. Bray, University of Missouri-Columbia

SOCIETY OFFICERS 1972

Henry W. Hamilton, President

VICE-PRESIDENTS

Leonard W. Blake

J. Allen Eichenberger

Dr. H. Lee Hoover

Dr. Carl H. Chapman, Secretary

Edward C. Matthews, Jr.

Clem T. Kelly

Leo J. Roedl

David R. Evans, Treasurer

TRUSTEES

Harold W. Mohrman, (Chairman)

Leo O. Anderson

Ramsey Bearden

Dale Belshe

John E. Berry

C. L. Blanton, Jr.

Freddie Bollinger

Fred Brandenburger

Mrs. Mary B. Bruno

C. Warren Cagle

Miss Harryette Campbell

R. I. Colborn

J. L. Connelly

Paul Corbin

J. M. Crick

Mrs. W. L. Davidson

W. B. Debo

Jack Dennis

Richard V. Dolby

Terrance Dyche

Benedict Ellis

Jim D. Feagins

Dr. Raymond Felling

Forrest Femmer

Charles R. Fiorita

Maynard A. Fisher

Michael R. Fisher

Howell Geiger

Henry H. Gerdes

J. W. Gerhardt

Harold Green

T. M. Hamilton

Dr. E. B. Hanan

Harry L. Harner

Dr. M. M. Hart

Dr. William Hayes

O. Lee Herberger

J. P. Herring

Leo P. Hopper

James G. Houser

Dr. Shelby Hughes

Elmo Ingenthron

Sam C. Irvine

Sam G. Jones

James F. Keefe

Thomas Keel, Jr.

David Kimbrough

George W. Kirk

Claude Knoles

Miss Margaret Lawlor

I. H. Lehmer

Dr. James L. Lowe

Frank Magre

Winton O. Meyer

Steve Miller

George W. Nichols

Dr. Peter Nichols

Charles V. Orr

W. L. Philyaw

Mrs. Howard Platz

Art Province

Julian D. Pyatt

Nelson Reed

Donovan Reynolds

Ralph G. Roberts

Paul V. Sellers

Dr. Francis L. Stubbs

John W. Taylor

Floyd Vavak

John C. Vinton

George Von Hoffman, Jr.

James Walden

PRESERVATION OF SITES COMMITTEE

J. J. McKinny (Chairman)

Joseph B. Abell

Dr. Hugh L. Cutler

William R. Denslow

Robert L. Elgin

Arthur L. Freeman, Jr.

Genevieve Huss

Charles E. Martien

Haysler A. Poague

Robert M. Seelen

George U. Shelby, Jr.

Allen B. Soper

Frank Stonner

C. H. Turner

Art. L. Wallhausen, Jr.

by Henry W. Hamilton & Jean Tyree Hamilton

We wish to express appreciation to all of the following for their help and assistance in the preparation of this report. The contributions of some are discussed in detail in the text, but we are grateful to each and every one.

Miss Wilsie Thornton, Mrs. Bess Franklin Mattox, Stuart M. Farrar and Jack Price, Pamplin, Virginia.

Dr. Clyde G. O’Brien, M.D.; Calvin Robinson, retired editor; Ray Noble and William Sperry, Appomattox, Virginia.

Mrs. Aldah B. Gordon, Clerk Circuit Court, Appomattox County, Appomattox, Virginia.

Vernon C. Womack, Clerk Circuit Court, Prince Edward County, Farmville, Virginia.

Alford L. Rector, Charles H. Meadows, and Mrs. Charles S. Martin, Appomattox Court House, National Historic Park, Virginia.

Edward A. Chappell, Virginia Historic Landmarks Commission, Richmond, Virginia.

Edward F. Heite, formerly with Virginia Historic Landmarks Commission.

Francis B. Fitzgerald, Suffolk, Virginia.

David Dautenhahn, Marshall, Missouri

John W. Walker, John W. Griffin and Richard D. Faust, Southeast Archaeological Center, National Park Service, Macon, Georgia.

J. Paul Hudson, Jamestown National Historic Park, Virginia.

Rex L. Wilson, Acting Chief, Division of Archaeology and Anthropology, National Park Service, Washington.

John C. Ewers, Smithsonian Institution, Washington.

Jerome E. Petsche, National Park Service, Washington.

Charles Phillips, Williamstown, Massachusetts.

Miss Mary M. Watts, Times-Dispatch, Richmond, Virginia.

Robert L. Saville, Jr., Lawyers Title Insurance Corp, Richmond Virginia.

Morton L. Wallerstein and Ralph Dombrower, Richmond, Partners in the last factory operation.

Microfilm Department, Virginia State Library, Richmond.

Miss Eleanor Thompson, Assistant Librarian, Missouri Valley College, Marshall, Missouri.

Mrs. Dorothy Erdmann, Summit County Historical Society, Akron, Ohio.

Floyd Painter, Editor, The Chesopiean, Norfolk, Virginia.

Ronald A. Thomas, State Archaeologist, Dover, Delaware.

Mrs. Elizabeth Schick and L. T. Alexander, Archaeological Society of Delaware, Wilmington.

R. H. Landon, Minnesota Archaeological Society, Minneapolis.

Howard A. MacCord, Sr., Archaeology Society of Virginia, Richmond, Virginia.

Ronald R. Switzer, Bertrand Conservation Laboratory, DeSoto National Wildlife Refuge, Missouri Valley, Iowa.

The photography is by T. M. Hamilton, Miami, Missouri, except where otherwise noted.

To the many others who have helped, we also wish to express our thanks.

This is presented as an aid in the identification of clay pipes from the general area of Pamplin, Virginia, that might appear in archaeological and historic sites. Interest in these pipes has been stimulated by their being reported as found in various sites in the western United States.

The circumstances under which this information has been gathered and the fact that it has been a number of years since clay pipes were made here, either as a home industry or commercially by the Pamplin Smoking Pipe and Manufacturing Company, leave much to be desired. On the other hand, in our work we have inspected a total of 4,451 Pamplin pipes; of this number 39% were from the factory grounds, and 61% were from the Thornton Store Site and represented the home industry, so we feel that the 39 forms presented represent at least a majority of the pipe forms made at Pamplin.

This is not to say that a similar form could not have been made elsewhere; however the style, the generally heavier and thicker character of the piece, and the finish, or lack of it, as well as the usual deep red color of the Virginia clay, would seem to make these pipes distinctive.

Under the conditions in which these pipes were retrieved it is obvious that the numbers of the different forms located give little indication of the relative numbers of the different styles that were manufactured, the popularity of the various styles, or the relative time of their manufacture.

Nearly all of the pipes examined were retrieved by excavation, by people who simply happened to become interested; this is equally true whether the pipes had been made by the factory and excavated out of fill on the old factory 3 grounds, or whether they were made at the homes and excavated from the basement of the old Thornton Store, which through the years had taken them in trade for merchandise.

In some cases among the pipes examined there were not more than one, or a few, examples of a certain form. In other cases there were hundreds. Among the examples available to us there was generally little variation in size within the same form. We have illustrated the largest and the smallest, since this also gives an opportunity to note minor variations that may exist between different molds for the same pipe form. However, a rather wide variation in size was present in that shown as (Plate 13 A), the “Original” Powhatan, where a total of 12 gradations from largest to smallest were found.

The predominant color of the pipes is dark red. A lighter color is infrequently present, running from almost yellow, to salmon, to light brown. The very dark, almost black coloration of some is said to come either from minerals present in the soil of this area, to which the pipes presented here had been subjected since nearly all had been many years underground, or from actual fire that had fallen into the saggers of the Company kiln, or the iron pots in which the pipes had been fired in the home industry.

During the last years of factory operation “some white clay from either West Virginia or Kentucky was shipped in by railroad”. This resulted in pipes of a lighter color, at times light grey to white. Apparently no pipes made from this particular clay were seen by us, except possibly those illustrated in Plate 23 AJ.

Well established local tradition indicates that clay pipemaking in the homes, for home and neighborhood use, started almost as soon as the first settlers reached the area, and after the suitability of the local clay was discovered. Initial county organization in this part of Virginia was well underway by the 1740’s.

Bradshaw’s History of Prince Edward County, Virginia, 1955, p. 5 states, Batho Austin road to be cleared from the Appomattox River near Colonel Richard Randolph’s quarter to Hill’s Fork on Vaughan’s Creek by all who lived near the route and were not employed on other roads. 1742.

Vernon C. Womack, Clerk of the Circuit Court, Prince Edward County, in a personal letter states, “Since the south fork of Vaughan’s Creek originates a short distance from where the pipe factory was later located in Pamplin, this might be the starting point. John Wood’s map of Prince Edward County, dated 1820 which shows that part that was later cut off to form Appomattox County, gives a detail network of roads through Kelso’s Old Store, which appears to be near the present location of Pamplin.”

There were stores at Sandy River, Wm. and Samuel Matthew had a store at Walker’s Church, and Kelso’s Old Store was between Walker’s Church and Merriman’s Shop (now Pamplin).” The statement is footnoted John Wood map, 1820. (Bradshaw, 1955:319).

Merriman’s Shop Post Office, 94 miles from Richmond, 185 miles from Washington. (Martin, 1835:269).

Advertisement for renewal of bids for rural route for port office in Merriman’s Shop in 1843-1848 (Bradshaw, 1955:315).

The area that was later to become Appomattox County had been, successively, included in the areas of several earlier and larger counties. Appomattox County was formed in 1845. The railroad came through Merriman’s Shop in 1854, and was renamed Pamplin. The Appomattox County Courthouse burned and the county records were destroyed by fire on February 2, 1892 (Communication from Mrs. Aldah Gordon).

Mrs. Bess Franklin Mattox reported, “Nicholas Pamplin, a resident of Merriman’s Shop, was the only citizen who permitted the railroad to go through his land without charge and so the village was renamed for him” (Mattox, personal communication). For a time it was known as Pamplin Depot, then Pamplin City, finally simply Pamplin.

The home manufacture of pipes has had a long history in this part of Virginia and can be considered as well underway by the 1740s. It existed long before the Company came to Pamplin and continued after the Company had ceased operations, or as long as there was an active demand for clay pipes.

The Home Industry finally came to a close in 1953. “Mrs. Betty Price of Appomattox County was the last to make pipes. I have a mold used by her. She made them from childhood and in her prime could make 40,000 pipes per year, having been taught by her mother in 1866 when she was eight years old. Her mother had made them a lifetime before her. In the last year of Mrs. Betty Price’s life, 1953, she made 500 pipes at the age of 95. They were made from clay from her own farm.” (Personal letter from Dr. Clyde G. O’Brien of Appomattox, and her son, Jack Price of Pamplin).

A column by the News-Leader correspondent from Appomattox, April 30, (year unknown) said, Hollywood bar reached all the way to Pamplin to get Mrs. Betty Price’s pipes for use by the Indians in the movie, “Northwest Mounted Police”. Cecil B. DeMille’s research man ferreted out the Powhatan pipe some months before the film went into production. Several dozen were ordered. Frank Lloyd also bought pipes to be used in the production of “Howards of Virginia”.

Practically speaking, all of the pipes made at the homes were made by white women, and from about the time of the first settlement of the territory, as the special suitability of the local clay for that purpose was early discovered.

Miss Wilsie Thornton of Pamplin said that this industry had become especially important after the War Between the States, because with so many men having been killed and the area in such straitened circumstances, the women 5 were badly in need of some means of making a living. The pipes they made could be traded at several general stores, or sold for a few cents, and there was no cost for materials.

One such establishment at which the local women disposed of their pipes was J. R. Franklin & Co., of Pamplin. Some of these pipes were recovered when the cargo of the sternwheeler, Bertrand, which sank in the Missouri River at Port La Force, Nebraska, April 1, 1865, (Petsche, 1970:1) was salvaged in 1968-69. The official list of artifacts recovered in the salvage operation, supplied by Jerome E. Petsche, National Park Service, who was in charge of that operation shows:

Pipes, Smoking; Several types and sizes recovered; briars and clay; one lot included clay bowls exclusively, others contained stems and bowls. Consignee: Vivian and Simpson, Virginia City. Manufacturer’s stenciling: ‘THE CELEBRATED VIRGINIA POWHATAN (CLAY), J. R. FRANKLIN & CO., SOLE AGENTS FOR THE MANUFACTURERS, PAMPLIN DEPOT, APPOMATTOX COUNTY, VA.’ Field lot numbers MPC 104, MPC 358, FSC 171.

The following description of the pipe shipment on the Bertrand was provided by Ronald R. Switzer, Director, Bertrand Conservation Laboratory, National Park Service, Missouri Valley, Iowa.

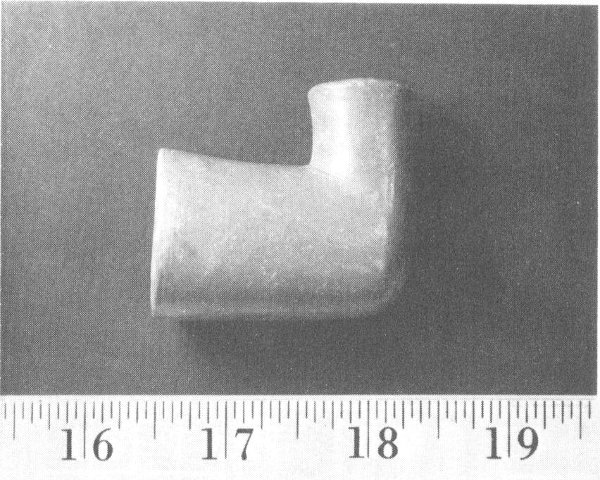

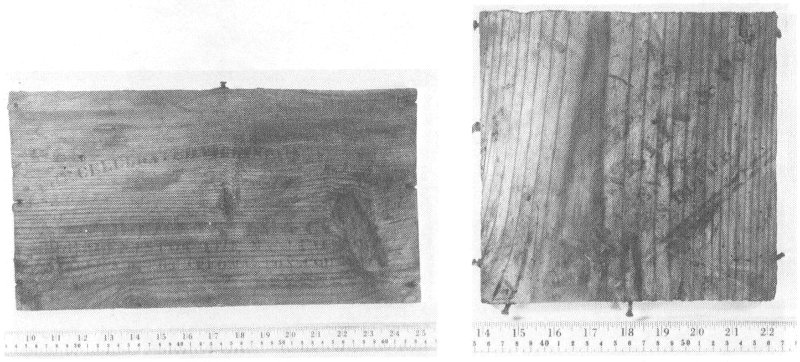

“The pipes are of one type and design (Plate 2). Forty pipe bowls plus 136 fragments ... all but 15 are chipped or broken, condition otherwise good. Clay, predominantly grayish-tan, mottled with brick red and brown. Paste soft, fine, and uniform, ... exterior has soft sheen. Preservation: Brushed with soft bristle brush in running tap water to remove mud.” (Switzer, personal communication).

This pipe is similar to (Plate 19 U); however, there are slight variations due to differences in individual molds made for production of the same pipe form.

The two pipe forms (Plate 19 T & U), were the only examples we found that carried the peculiar pinkish-gray tan color, and they were found only among the pipes made by the Home Industry. They were probably made of clay from the same source and by the same individual, since home pipemakers usually dug their clay on their own premises, and the condition of the pipes, after a century in mud and moisture, indicates that the work was done well.

The shipment was contained in a wooden box, which was approximately 15½ inches long, 8½ inches wide, and 8 inches tall (Plate 2). The stenciling on the box is faint, but legible.

“Lettering on the top of the box indicated the consignee but is so faded that it was impossible to obtain a good photograph; however the stencil once read,—B. A. L. Vivian & Simpson, Virginia City, M. T.” (Plate 3) (Switzer, personal communication).

“One end of the box was lettered, No. 1, 216, M. Size” (Plate 3). The meaning of this can only be conjectured, however it may have indicated shipment No. 1, to this consignee; containing 216 pipes; of Medium size.

The stencils identifying the consignor, J. R. Franklin & Co., appeared on 6 both sides of the box and were identical (Plate 3). The same, except in abbreviated form, appeared diagonally on one end of the box.

The account book of the store at New Store, Virginia, about 23 miles northeast of Pamplin, which is in the collections at Appomattox Courthouse, records that on Sept. 1, 1866, I. H. Schenault was paid $8.00 for 1,600 pipes, and later, (apparently the same day) was paid $8.75 for 2,175 pipes. The latter was evidently a partial and immediate “in trade” transaction.

So in the Pamplin area in the 1860s general stores were taking clay pipes made in the home industry, allowing about ½¢ each in trade for commodities, and at least in one instance were shipping them west for use by the miners in the gold fields.

Mrs. Betty Price has said that the Powhatan “Original” (Plate 13 A) the “Hamburg” (Plate 14 F) and the “Zuvee” or “Zoo” (Plate 19 T) were some of the first pipe forms made in the area. (News-Leader, April 30, year unknown).

Many of the clay pipes made at homes near Pamplin were traded for commodities at the Thornton General Store in Pamplin, and this store was truly “general”, for it handled, in addition to groceries, everything from threshing machines and horsepower mills to silk thread.

Miss Wilsie Thornton had a copy of her Father’s letterhead: the letter was dated, Jan. 9, 1892. The letterhead reads,—

W. D. THORNTON, DEALER.

General Merchandise and Agricultural Implements.

Wholesale dealer in All Styles of Clay Pipes and Stems

Manufacturer’s Agent for

Aultman and Taylor Threshers, Horse Power and Farm Engines.

Also Buckeye Reapers & Mowers & Thornmill Wagons.

“The pipes made by the local women,” Miss Thompson said, “were traded to the Thornton Store for the necessities of life. The pipes were stored in the basement of the store and packed in barrels, in either pine needles or sawdust, and shipped to the Baltimore Bargain House, or to other wholesale houses. From the wholesale houses they were shipped to the Cotton States and to the West. Large orders were filled for a tobacco factory in Pennsylvania, where they sold bags of tobacco with the pipes.”

Pamplin pipes have been reported from the sites of Fort Laramie, Wyoming; Fort Sanders, Wyoming; Fort Stambaugh, Wyoming; Fort Phil Kearny, Wyoming; Fort Union, New Mexico; Fort Sully, South Dakota; and Fort Davis, Texas (Wilson, 1971).

Miss Thornton’s parents were married in 1874, but the store was already in operation at that time. Her father continued operation until his death, December 16, 1897; after that the store was run by her brother. A bank, the “Farmer’s and Merchant’s National Bank” was also operated in the store. In later years the building became a drug store.

Finally with time and disuse the old building came down and erosion, with perhaps some intentional filling of the area, took place. So the site of the old general store, which in its heyday had meant so much to Pamplin and Appomattox County and its people in their daily living, became simply a vacant area.

Some years ago Miss Thornton had made a train trip and met an old colored woman in a rest room to which they had both gone to smoke. (When we met her, Miss Thornton chain-smoked at the age of 89). The colored woman had a sack of tobacco and pulled out a clay pipe which Miss Thornton recognized as of the kind that her father used to take in trade, so she asked the woman if it was a good one.

The woman answered, “Law, yes, but I can’t buy them any more!” so Miss Thornton told her that it was made long ago, in her home town, and that she would try to get her some.

Her next problem was to find some pipes. After several days she thought of the pipes that she felt sure were covered with earth and still in the basement of her father’s old store, so she talked to her cousin and next door neighbor, Mrs. Bess Franklin Mattox.

Shortly after that, they dug at the site. Mrs. Mattox thinks it was around 1958, though possibly 2 years earlier. “Erosion through the years had covered the pipes and when we first started to dig we found none, then there they were, under the dirt. We found two or three sugar barrels full. Tar was on a few of the pipes, from road tar that was also stored in the basement and spilled”. (This tar, in hard-dried rough spots, is present on some of the pipes we examined; however it chips off readily and leaves the pipe relatively clean).

So the colored woman who couldn’t find a Pamplin pipe to buy received “either 15 or 16” and Miss Thornton received a letter of thanks from her from Atlanta.

Miss Thornton still had approximately 1,450 of the home manufactured pipes for us to see when we visited her in July 1969, and Mrs. Mattox had a few.

Dr. Clyde G. O’Brien of Appomattox has had a lifelong interest in the clay pipes of his area and in the history of their manufacture. He has a collection of pipes as well as two pipe molds, and has given us much information.

We asked Dr. O’Brien for an account of the method of making pipes in the homes. The following is his contribution, in a letter dated March 11, 1971.

“I talked to Jack Price, age 86, he had worked in the plant for years. His mother, Mrs. Betty Price, and grandmother made pipes at home in Pamplin.

“The clay was made up and put into molds, when the pipe was removed from the mold the shaper was used to smooth mold marks, if the pipe was to be identified with ‘Original’, ‘Hayiti’, or some other marking this was impressed 8 on the base with a stamp at this time. The pipe was then sun-dried on a board in summer, or in the stove oven in winter. Then after they had ‘set-up’ the pipes were put into an iron pot, the pots were put into an oven in the back yard and dry chestnut wood was placed around the pots and this was then set on fire. They did not have a thermometer so he did not know the temperature, but when the wood had burned completely the pipes were brought out to cool.

“If a piece of wood fell into the burning pot and started to smoke it was removed at once to keep from blackening or staining the pipes.

“After the pipes cooled they were brought into the house and Mr. Price said that when the pipes were poured out of the pot in which they were baked, to the floor, they would ring or chime when they hit against each other.

“The pipes were then waxed with bee’s wax and mutton tallow and then polished with a woolen cloth, and the children helped.”

In all of this, Bob Davis of Pamplin, age 91, in talking to John W. Walker in 1962, had concurred. He said, “The pipes were molded, trimmed, put on a board and dried in the sun, baked in iron pots, waxed, and rubbed. The pipes were made all through the country, the local stores bought and shipped them, and the Factory would buy these ‘country pipes’.” Here was more direct evidence that the Factory, on occasion at least, bought and shipped pipes made by the Home Industry (Walker, personal communication).

There were, however, two men who made pipes.

Dr. O’Brien’s father Thomas O’Brien, was born in 1843. When he came back after the War, about 1865, he made his own mold of white-oak with lead lining and made pipes for his own use.

According to Miss Wilsie Thornton, a Mr. Rodgers was making molds and pipes until about 1938 as a hobby. One of them was in the form of an Indian head (Plate 23 AL). The “peach seed” pipe (Plate 23 AM) is also thought to be one of his manufacture.

In the middle 1850’s that part of Ohio that surrounds Akron was the pipemaking capital of the United States, with at least six clay products companies producing them (Blair, 1965:26-30). The leading producer of clay smoking pipes in the Akron vicinity was the E. H. Merrill Co., which had been producing pottery objects since its founding in 1831. In 1843 or 1844 Calvin, brother of E. H. Merrill, invented a machine for making pipes which greatly increased the output of the company and gave quite an advantage over its competitors (Blair, 1965:3).

The Pamplin Smoking Pipe and Manufacturing Company, Inc., was established by the Akron Smoking Pipe Company of Akron, Ohio, when they built the plant at Pamplin.

That the clay in Appomattox County was well suited to pipe manufacture was well known. The establishment of this plant was no doubt the result of the 9 Company’s realization of the availability of the fine red clay from which the local women were producing pipes, a clay that could be used without even sifting.

When the Pamplin Factory was established is quite uncertain. Examination of the microfilm of newspapers of the area that were available from the Virginia State Library, beginning February 3, 1869 through December 25, 1896, gave no clue to the date of the establishment of the Pamplin Factory, nor did county records, probably due to the fire of 1892.

Sometime immediately prior to 1880 William Merrill of Akron, Ohio, undoubtedly a member of the pipe making family, established a pipe making factory at Pamplin. (Omwake, 1967:23). Our Pamplin informants were of the opinion that the Akron plant was devoted to the manufacture of drain tile after the pipe machinery was moved to Pamplin.

Bob Davis of Pamplin, born 1871, in an interview with John W. Walker in September 1962, said, “I was a kid when the factory came in”. Timewise this would be in general agreement with Omwake’s estimate for the date of the establishment of the factory at Pamplin.

That Pamplin pipes were also available from Akron in 1893 is evidenced by a letterhead of the Akron Smoking Pipe Company, dated June 26, 1893, showing examples of two clay pipes similar to Plate 22 AF & AG, (Blair, 1965:36). A communication from the Summit County Historical Society reports, “The Akron Smoking Pipe Co. is recorded as being in business from 1891 to 1895, and were manufacturers of stone, Powhatan Clay, and corn cob tobacco pipes. Daily capacity 100,000 pipes. General offices, Akron, Ohio. Factories, Pamplin City, Virginia; Mogadore, Ohio.”

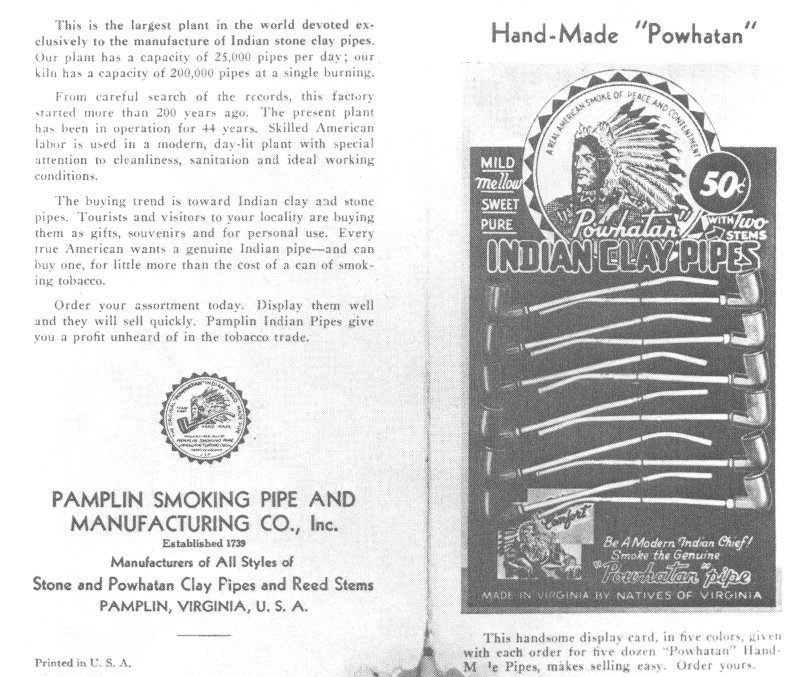

Statements in company literature are also confusing. In a leaflet which carries a testimonial for their pipes, dated April 28, 1941 and price lists “effective November 15, 1941”, the statement is made, from careful search of the records, this factory started more than 200 years ago ... the present plant has been in operation for 44 years. Skilled American labor is used in a modern, day-lit plant with special attention to cleanliness, sanitation, and ideal working conditions (Plate 8).

This would give a date for the “present plant” of 1897, but it also suggests that an earlier plant had been rebuilt or replaced. (An undated and unidentified news clipping does state that at some time the pipe plant had burned). Company literature also states, “Established 1739” (Plate 8). This obviously cannot refer to the establishment of the plant, nor even to the mother plant at Akron, since pottery was first produced in Summit County, Ohio, in 1828 (Blair, 1965:2). The Company may simply have been employing “poet’s license” and appropriated a date which they felt representative of the start of the Home Pipe Making Industry in the Pamplin area.

The Times-Virginian of Appomattox, date unknown, carried a news article, Pamplin Clay Pipe Plant once termed largest in the World. The Farmville Herald of March 29, 1935 stated, ... the output of the Clay Pipe Factory at Pamplin is 1,000,000 a month, when it is running full time. In the roster of business in Virginia, this factory is mentioned as the largest clay pipe factory in the United States, and so far as is known, in the world.

At one point in the history of the plant, pipes were sold to England as well as some other countries in Europe.

Also vague has been the terminal date of the Pamplin Company; it is variously given locally as 1948 to 1951.

There is a contemporary news article on the factory published in the Richmond Times-Dispatch, April 21, 1946. A History of Appomattox, Virginia, published 1948, states, The Akron Pipe Factory of Pamplin holds the title of manufacturing the finest clay smoking pipes in the world, known as the ‘Powhatan’ (Featherstone, 1948:44).

In a personal letter to the writers, John C. Ewers said, “During my field work on the Fort Peck Reservation in Montana, in 1953, I first learned of the Pamplin clay pipes. One of my Indian informants told me about selling them when he was working at a trading post on the reservation during the first decade of the present century....

“Later I visited the trading post at Oswego on the Fort Peck Reservation. There the proprietor showed me the illustrated price list of the Pamplin Smoking Pipe and Manufacturing Company, Inc. He showed me the only type of pipe he still had in stock—the ‘Century of Progress’, Chicago type (Plate 23 AJ). He said the manufacturer wrote him in 1951 that he planned to go back into the manufacture of the other styles, which the Assiniboine preferred.”

The Tomahawk pipe was a good specialty item for sale at such events as fairs and expositions, and the Company’s sales to the “Century of Progress” in Chicago in 1933 must have been excellent, even though they had not sold all they had made in anticipation of that demand. The bowl, necessarily narrow and elongated since it was in the blade of the tomahawk, did not recommend it to serious smokers, nor to the Assiniboine.

It would seem evident that these pipes were left over from the production of the Company in 1933, that their regular pipe models had by this time been sold out, and that the Company was already in a State of quiescence in 1951.

Dr. Clyde G. O’Brien of Appomattox stated that the Company ceased operations in 1951.

The Charter of the Pamplin Smoking Pipe and Manufacturing Company shows that it was incorporated by the Commonwealth of Virginia on the 15th day of August, 1929. The officers at that time were, J. V. Lewis, Pres., Prospect, Virginia; J. W. Franklin, V.Pres., Pamplin; L. N. Ligon, V.Pres., Pamplin; T. R. Pugh, Secy-Treas., Pamplin.

The purposes of the Company then were, among other things, to deal in wood of all kinds, own timber lands, contract to do construction work, deal in real estate, and to buy and sell all kinds of necessary material ... and operate all the necessary equipment and machinery for the purpose of manufacturing clay pipes, crocks, and earthenware.... (Charter Book No. 1, Page 108, Appomattox County, Virginia). The corporation (Charter No. 34565-16) was dissolved by the State Corporation Commission, at the request of the stockholders, on February 21, 1952.

A personal communication, February 23, 1972, from Morton L. Wallerstein who with Ralph L. Dombrower as corporate officers were the last active operators of the pipe factory, states, “Mr. Dombrower and myself, as sole stockholders, started the operation in 1938 and baked the clay pipes up to the time of the enactment of the Minimum Wage Law by Congress. At that time it was apparent that the part-time workers, largely farm girls and boys who worked in the afternoon, would cease to be employed because the pipes could not be marketed under the wages required to be paid.

“However, Mrs. Betty Price and another woman made the hand-made clay pipes at their homes, which pipes Mr. Dombrower bought after 1938 and very cleverly boxed in antique fashion and sold them for some years. However, unfortunately the women who made these pipes died and they were no longer made.

“The factory, itself, did not manufacture pipes beyond the period stated above. The property was sold in 1947 and the corporation was dissolved in 1952.”

Apparently then, the Pamplin Smoking Pipe and Manufacturing Company ceased all activity in 1951, having been in existence slightly more than 70 years.

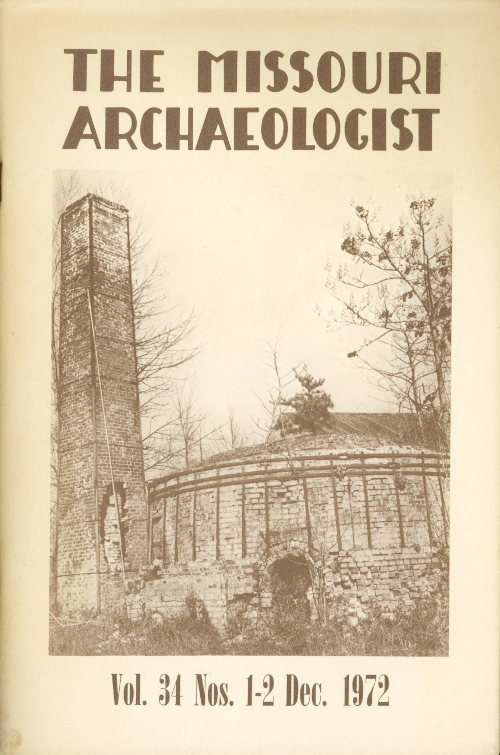

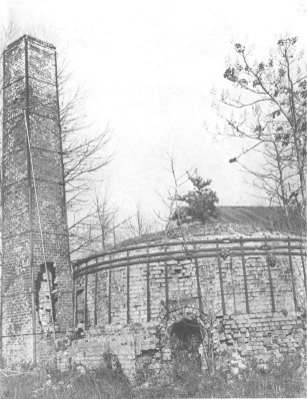

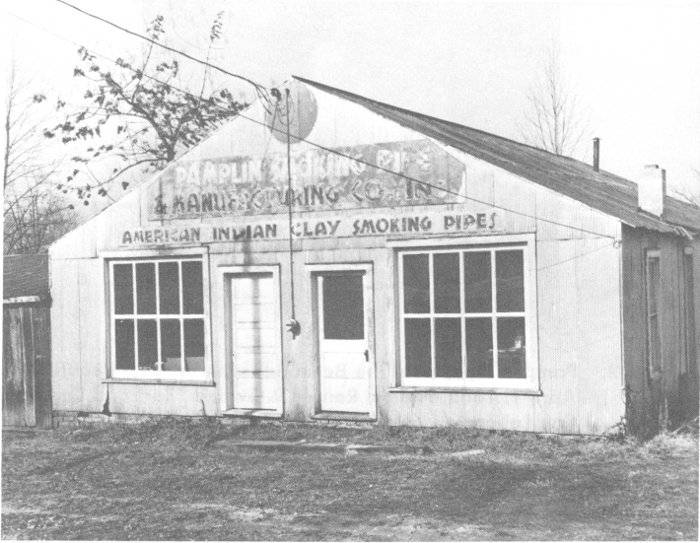

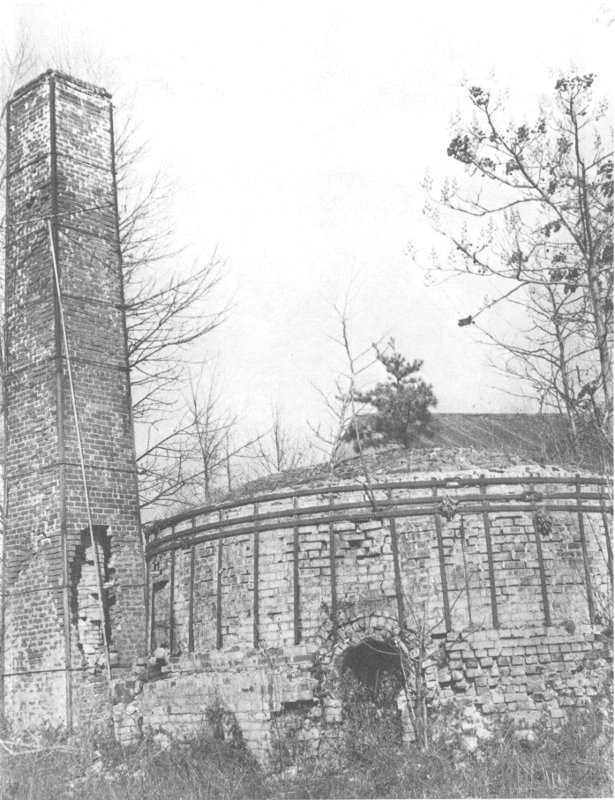

Some time after the closing, the main factory building was used as a garage. In July of 1969 this frame building, with the name “Pamplin Smoking Pipe and Manufacturing Co., Inc., American Indian Clay Smoking Pipes” still painted above the entrance, stood unoccupied; the crumbling old smokestack and large round kiln of brick construction were still there (Plates 4 & 5). Another building which had served Company purposes had been destroyed.

The machinery to mold smoking pipes and bottles was invented by Calvin J. Merrill of the E. H. Merrill Pottery, Summit County, Ohio, in 1843 (Blair, 1965:3).

The pipe machine was simple: the individual metal molds in the foot powered mechanism could be changed to vary the pipe form. The whole was contained in a simple wooden bench (Plate 6). Miss Wilsie Thornton felt that a man working such a machine could produce thousands of pipes per day. It is unknown how many such machines were used by the factory, nor how many people were employed since ideas of our informants varied; however, the best estimate seems to be 8 to 10 machines, with employees varying from 10 to 40, depending upon the press of work and the rush of orders at any given time.

Bob Davis of Pamplin, in the interview with John W. Walker said, “Old man Taz Harvey made the Powhatan mold. He had a shop and made many molds”.

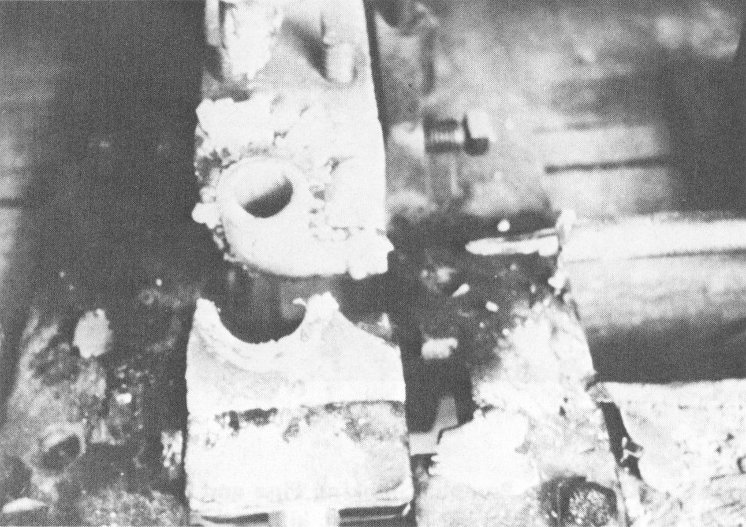

The pipes were packed in round stoneware crocks or saggers made from fireclay, and the saggers were stacked alternately around the kiln. The saggers were some eight inches high and 16 to 18 inches in diameter (Plate 7). There was an opening in the top of the kiln through which, in glazing, salt was put when the pipes were hot. They were fired some 24 or 48 hours (Miss Thornton’s statement).

Mrs. Maddox said: “As a child I used to go with a colored man who worked with us and also for the factory, and watch him throw salt down a hole in the top of the kiln on the pipes to make a glaze.”

At a high temperature the salt vaporized and combined with the silica in the body of the clay to form a glassy or ‘silicate glaze’. The kiln was fired 32 to 36 hours before maximum temperature was reached; it was cooled the same period to prevent crazing (minute cracking) of the glaze (Blair, 1965:15). This description of glazing refers to stoneware in the mid-nineteenth century potteries near Akron, Ohio. However since the Pamplin kiln was the same sort of “walk-in” kiln, the detail would fit, and it is substantiated by Miss Thornton’s statement of firing time.

From the scarcity of glazed pipes among the many that we examined, we conclude that the majority were finished without glazing.

The stems sold with the factory pipes were made from switch cane Arundinara gigantea known locally as reed and once abundant in the Great Dismal Swamp in southeastern Virginia (R. H. Woodling to Chas. H. Meadows, May 15, 1969). (The stems used with the pipes made by the Home Industry usually came from the same source.)

The reeds were cut in 12 foot lengths by men in boats, allowed to dry for six months, cut in lengths and reamed out. Some were put in a machine and bent (Miss Thornton, Dr. O’Brien).

Cork plugs or washers were used in the base of the pipes to hold the stem in place. Some were still in place in pipes we examined. A plug mill, a high pressure machine, extruded the cork plugs which were cut off by wire (Heite).

(Replacement reed stems for clay, hickory, or corn cob pipes, retailed in the grocery stores in Lexington, Missouri, for 10¢ per dozen about 1916).

A number of people and institutions with varying numbers of Pamplin Factory pipes in their possession have given us an opportunity to examine them. The largest number of specimens were in the hands of the following.

Our attention was first called to these pipes in 1968 at the Craft Club in 13 Arrow Rock, Missouri, where some of them appeared for sale as an unusual item. They obviously had been underground, for the bowls and bases were still filled with earth containing numerous rootlets growing through the pipe cavities.

It was learned that the pipes had been supplied by Francis B. Fitzgerald, Suffolk, Virginia; David I. Dautenhahn, Marshall, Missouri, put us in touch with him. As a youngster, Fitzgerald had on various occasions visited his grandfather’s farm, which was near the Pamplin Factory, and had played in the water of a little creek on pipe plant property. In so doing, he discovered that there were numerous clay pipes in a bank which apparently had been placed in the creek to form a dam. (The dam was probably for the purpose of retaining water to mix with the clay). He had hundreds of these pipes. Practically none would seem to have been rejects—how or why they got into the dirt which was used to make the fill is unknown. Through the years Fitzgerald had made a selection of forms representative of this group, all of which he made available to us.

Since that time an owner of the pipe plant property had secured many pipes, later acquired by the Appomattox National Historic Park. They were made available to us by Alford L. Rechtor, Superintendent.

The Virginia Historic Landmarks Commission supplied photographs of some Pamplin pipes, as well as photographs of a pipe mold and pipe maker’s bench (Plate 6) and saggers (Plate 7). We were granted the use of these by Edward F. Heite and Edward A. Chappell of that institution.

John W. Walker of the National Park Service, who had worked in the area and become interested in the pipes made there, provided us with a copy of his field notes and some examples of pipes.

John C. Ewers of the Smithsonian Institution had visited Pamplin. He gave us much information and showed us several pipe forms from the area that are in the collections of that institution.

Rex L. Wilson, National Park Service, loaned us a copy of his manuscript, “Clay Tobacco Pipes from Fort Laramie, Wyoming and Related Sites”, in which he identified some specimens as having come from Pamplin.

The Company’s price list of November 1941 listed “The Powhatan Machine Made”, fitted with cork closures and 10″ reed stems, bowls trade-marked, packed 50 to box, 25¢ retailer. Price $6.00 per box.” (Plate 10).

Five other models were listed, “5 in. reed stems, packed 100 to box, 15¢ retailer. Price $3.00 per box.” Two models were listed similarly, but 10¢ retailers, price $2.50 per box. Two other 10¢ retailers were listed at $2.70 per box, and one model at $2.85 per box but the suggested retail price was still 10¢ each.

One model, their “Ole Virginny Hamburg”, was offered in finest fire-clay, hard-burned, white, simulates meerschaum, also in red. Similar to “Ole Virginny Shaker”. It was a 10¢ retailer, $2.70 per box of 100. (It is of interest that this 14 pipe, listed elsewhere in this same price list, but as “Ole Virginny Shaker of Virginia red clay, a heavier stone pipe”, was priced as a 15¢ retailer and $3.00 per box). (Plate 10).

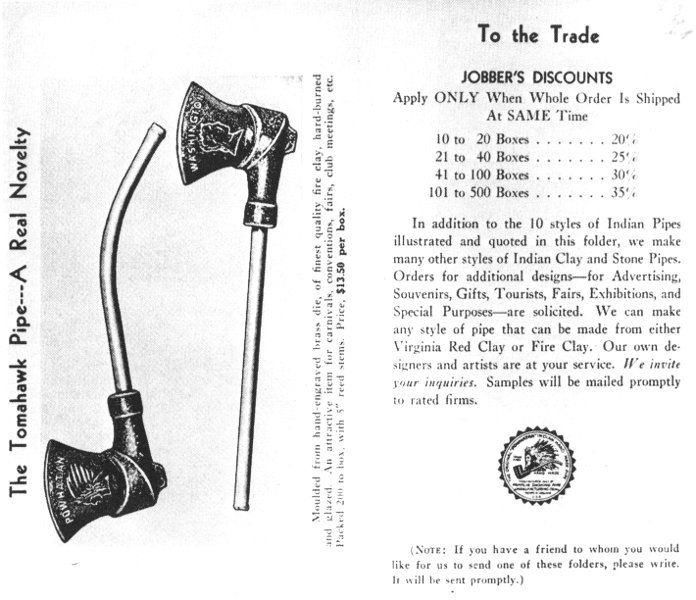

Jobbers discounts were offered. “10 to 20 boxes, 20%”, and going up by 5% stages to “101 to 500 boxes, 35% discount”. “We make many other styles of Indian Clay and Stone Pipes, ... we can make any style of pipe that can be made of clay. Our own designers and artists are at your service” (Plate 11).

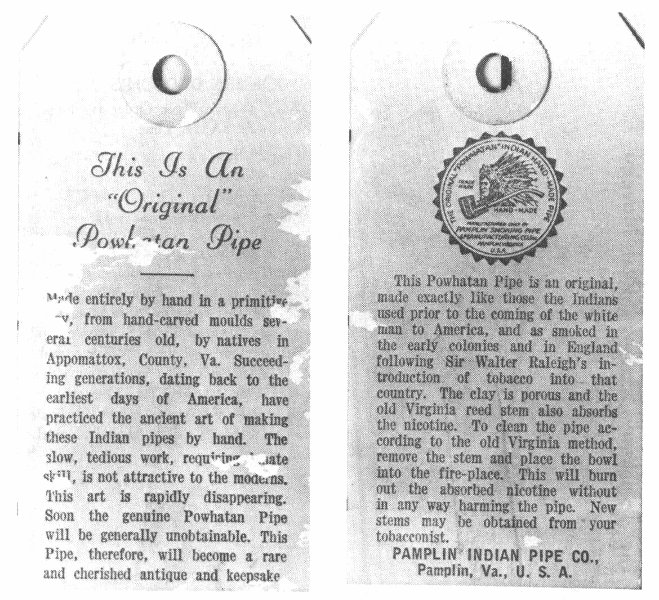

In the last years of Factory operation their sales carried an identification tag, “This Is An ‘Original’ Powhatan Pipe”, and it was being made by the last two women of the Pamplin area who were still making pipes at their homes (Plate 12).

The pipes are illustrated natural size. The largest and the smallest pipe of each form available to us are shown. In many instances this difference in size is not great; however, it does illustrate that minor variations often existed in different molds for the same pipe form. The diameters for the stem openings have not been included since they have proved useful only in consideration of the earlier integral-stem clays, and not for consideration of the “short-base” pipes of the type and time included in this report (Wilson, 1971:2).

| TABLE NO. 1. | ||

|---|---|---|

| Sources of Pipes, and Relative Numbers Available for Examination. | ||

| Total number of pipes inspected—4,451. | ||

| Plate. | Source. | Number of Examples. |

| 13 A. | Both | Many |

| 13 B. | Home | 2 |

| 13 C. | Home | 11 |

| 14 D. | Home | 4 |

| 14 E. | Home | Many |

| 14 F. | Both | Many |

| 15 G. | Factory | Many |

| 15 H. | Home | 3 |

| 15 I. | Factory | Many |

| 16 J. | Factory | Many |

| 16 K. | Both | Many |

| 16 L. | Factory | Many |

| 17 M. | Both | 37 |

| 17 N. | Factory | 1 |

| 17 O. | Factory | 1 |

| 17 P. | Both | Many |

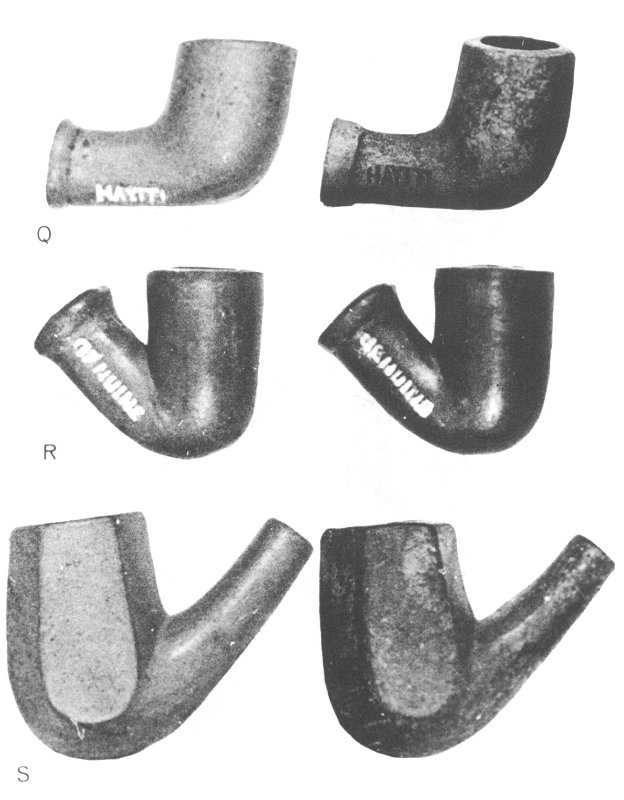

| 18 Q. | Both | Many |

| 18 R. | Home | 10 |

| 18 S. | Both | Many |

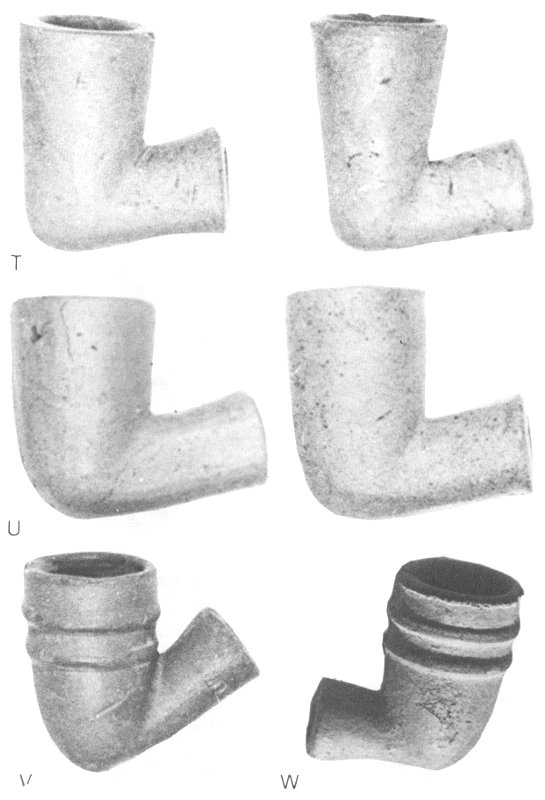

| 19 T. | Home | 14 |

| 19 U. | Home | 2 |

| 19 V. | Factory | 1 |

| 19 W. | Surface | 1 |

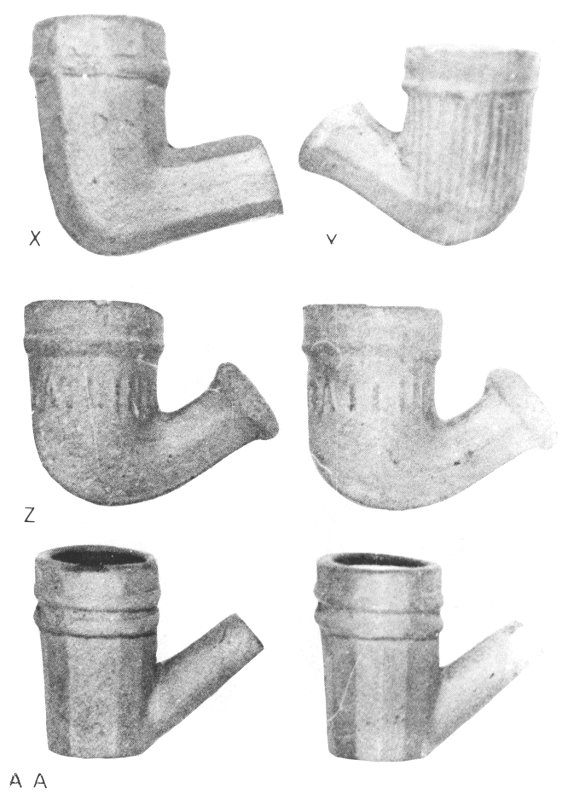

| 20 X. | Factory | 1 |

| 20 Y. | Both | 2 |

| 20 Z. | Factory | 4 |

| 20 AA. | Factory | 4 |

| 21 AB. | Factory | 1 |

| 21 AC. | Home | 1 |

| 21 AD. | Factory | 1 |

| 21 AE. | Factory | 1 |

| 22 AF. | Factory | 2 |

| 22 AG. | Factory | 1 |

| 22 AH. | Factory | 1 |

| 22 AI. | Factory | 2 |

| 23 AJ. | Factory | 1 |

| 23 AK. | Factory | 1 |

| 23 AL. | Surface | 1 |

| 23 AM. | Home | 2 |

| TABLE NO. 2 | |||

|---|---|---|---|

| Identifications Appearing On Certain Pamplin Pipes. | |||

| Plate: | Source of Pipe. | Designation. | Lettering. |

| 13 A. | Both | Original | Impressed |

| 13 B. | Home | Original | Impressed |

| 17 M. | Both | Original or Florence | Impressed |

| 18 Q. | Both | Hayiti | Impressed |

| 18 R. | Home | Genuine | Impressed |

| 19 V. | Factory | 117 | Raised |

| 20 Z. | Factory | Catlins | Raised |

| 20 AA. | Factory | 103 | Raised |

| 21 AC. | Home | Original | Impressed |

| 21 AD. | Factory | Powhatan | Impressed |

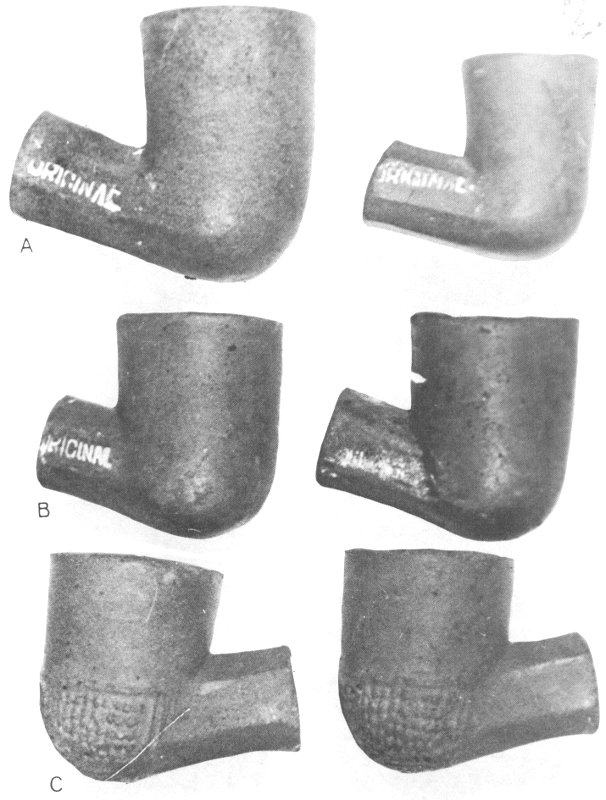

Plate 13 A. Slightly Acute Angle. Made both in the factory and in the home. Many examples. All are a deep, dark, glossy red, except 9 pipes which were a light brown. Plain round bowl, octagonal base. It was made in at least 12 slightly varying sizes, there being that many variations between the large and the small pipe illustrated. This was the Pamplin Company’s “Original” Powhatan, and it was no doubt one of the Company’s leaders in production and sales. The word “ORIGINAL” is impressed in the right side of each base, with the exception of one single pipe, and the lettering appears in at least three different sizes, there being no correlation between the letter size and pipe size. This is a sturdily made pipe.

The Company emphasized in its publicity that the Indians had originally demonstrated to the early settlers the method of making the Powhatan and so had enabled them to make this exact form, thereby inferring that this model should have been of particular interest and worth. No doubt at some time and place in our history a happening of this nature may have occurred. However, the Powhatan is a usual form which has been found in aboriginal sites, with some modifications and of varying materials, over a wide area.

Many of these pipes appeared, both from the factory site and among those made by local women and retrieved from the basement of the Thornton General Store. Mrs. Betty Price said that this form was a standard product of the local Home Industry pipe makers before the factory ever came to Pamplin and one of the earliest made in the area. All of the pipes available to us carried the designation “Original” except one.

The making of clay pipes was an old and well established business at Pamplin; whether the impressing of the word ORIGINAL on the base of this pipe was an innovation of the Pamplin Smoking Pipe and Manufacturing Company, or whether this had been long done by the Home Industry is unknown.

Plate 13 B. Slightly Acute Angle. Home. 2 examples. Dark red. Plain round bowl, octagonal base. Quite similar to “A” except both bowl and base are shorter, and diameter of bowl proportionally larger. “ORIGINAL” is impressed on right side of base. A very sturdy pipe.

Plate 13 C. Slightly Acute Angle. Home. 11 examples. Glossy dark red. Round bowl, octagonal base. Upper part of bowl plain, lower front portion decorated with a series of raised dots. The dotted area is divided into two triangles, as well as separated from the undecorated area by raised and rounded bands. The mold marks in the undecorated area have been almost entirely smoothed. It would seem that all pipes of this form came from the same mold, in contrast to the fact that at least most other Pamplin pipe forms seem to have come from a number of different molds.

The two pipe forms “C” and “B” are quite similar, except that “C” has decoration as well as a slightly longer base, and is not marked “Original” Both are sturdily built, with thicker than average bowl walls, and both were retrieved from the Thornton Store site; no examples were found at the factory site. They are probably the product of the same individual woman working at her home.

Plate 14 D. Slightly Acute Angle. Home. 4 examples. This is a black pipe. The deep, solid color was probably intentionally achieved by allowing portions of the burning wood of the kiln to fall into the iron kettles which were used as saggers for the firing of pipes in the Home Industry. The bowl and base are round, with diagonal cross-hatched decoration on bowl, separated from the same decoration on remainder of base by a narrow rounded band. Flat band at both top of bowl and end of base. The right and left halves of the pipe are separated from each other, front and back, by a broad smooth ridge covering the mold mark.

Plate 14 E. Slightly Acute Angle. Home. Many examples. Bright red. Bowl and base decoration similar to “D”, but this form is somewhat smaller than “D”. Double band at both top of bowl and end of base, the outside band broad and flat, inside band narrow and rounded. Only slight variations in size.

Plate 14 F. Right Angle. Both. Many examples. Dull red. The Company called this their “Akron Hamburg”. The diagonally cross-hatched bowl decoration 17 is separated from the diagonal line base decoration by a rounded band. Double band at both top of bowl and end of base, the outside band broad and flat, the inside band narrow and rounded. The right and left halves of the pipe are divided from each other, front and back, by a broad smooth ridge covering the mold mark. Only slight variations in size.

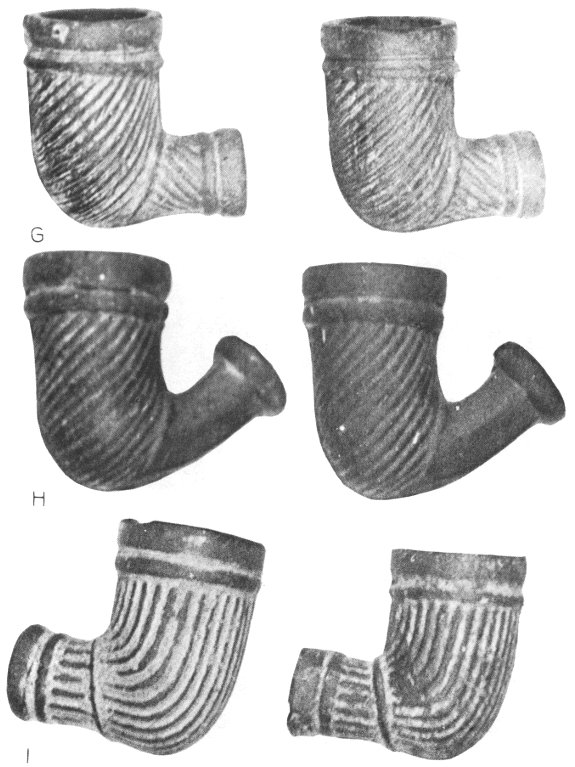

Plate 15 G. Right Angle. Factory. Many examples. Dull red. Diagonal line decoration on bowl runs at right angles to that on base. Double band at top of bowl and stem end of base, outside band flat, inside band narrower and rounded. The right and left halves of the pipe are divided from each other, front and back, by a broad smooth ridge which covers the mold mark. Two slightly different sizes.

Plate 15 H. Acute Angle. Home. 3 examples. Dull, dark red. Spiral decoration on bowl, plain hexagonal base. Double band at top of bowl, upper flat, lower rounded. Large rounded band at end of base.

Plate 15 I. Right Angle. Factory. Many examples. Dull, dark red; a few are light brown. The Company called this model their “Ole Virginny Shaker”. Grooves of decoration run vertically on bowl and curve toward the bottom to stop at a rounded band, then continue horizontally to stem end of base. Double band at top of bowl, upper flat, lower rounded. Double band at stem end of base, inside band rounded; the outside band may be either rounded or flat; if flat, the end of base is noticeably swelled. Five slightly varying sizes.

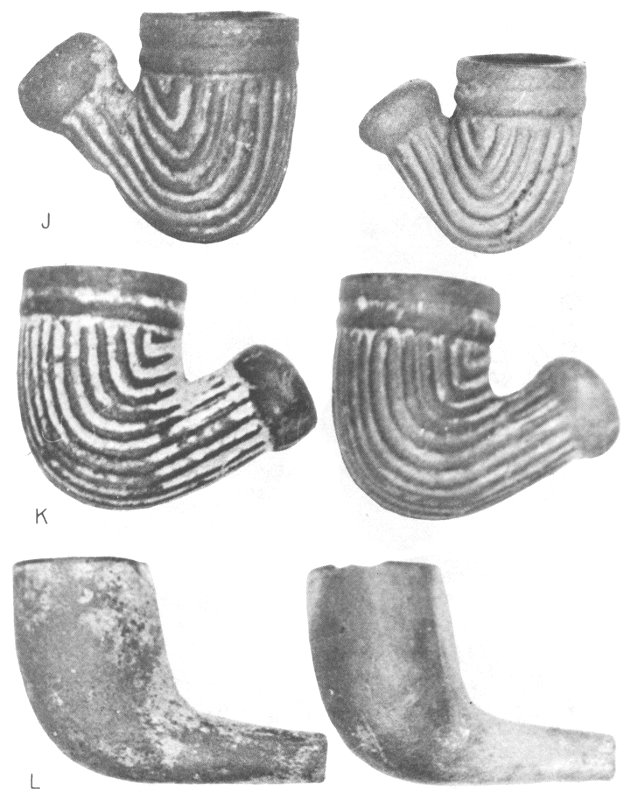

Plate 16 J. Sharply acute Angle. Factory. Many examples. Dark red. Broad grooves of decoration run from top of bowl and curve toward bottom to continue to stem end of base, or curve back around bowl. Double band at top of bowl, upper flat, lower rounded. Prominent rounded swell at stem end of base. At least 4 different sizes.

Plate 16 K. Acute Angle. Both. Many examples. Dull red to dark brown. Quite similar to “J” in form and decoration except that lines of decoration are more narrow and the bowl does not set at such an acute angle to base. Only slight variations in size.

Plate 16 L. Obtuse Angle. Factory. Many examples. Dark red to brown. Round undecorated bowl and round tapering base. These pipes are somewhat similar to early stemmed clay imports except that the base is cut off rather short, to form a flat vertical face, instead of terminating in a stem which was an integral part of the bowl and base. The opening in the end of the base is quite small and does not have the usual taper. All of the pipes of this form are nearly identical in size.

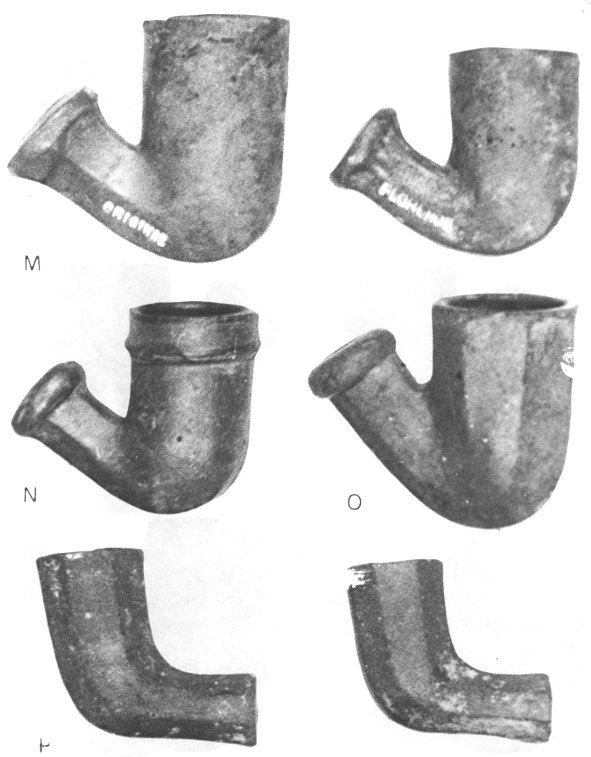

Plate 17 M. Acute Angle. Both Home and Factory products, 37 examples. Bright, light red. Plain round bowl, hexagonal base expanding to a bell-shaped swell at stem end of base. The flat bottom extends around and under the bowl. “ORIGINAL” is impressed in the right side of base of some examples and “FLORENCE” in others, while some have no wording. The factory examples that we saw were marked either “ORIGINAL” or “FLORENCE”, as were some 18 of those of home manufacture; however, 16 pipes of home manufacture had no wording. At least three sizes are represented.

Plate 17 N. Acute Angle. Factory. One Example. Dull, dark red. Similar to “M” except heavy rounded band of beading around near top of bowl, no wording. Hexagonal base expands to a bell-shaped swell at stem end. Mold marks are more distinct.

Plate 17 O. Acute Angle. Factory. One example. Dull, dark red. Plain octagonal bowl, with planes continuing along base to large rounded swell at stem end. From deep in the dam at factory site.

Plate 17 P. Obtuse Angle. Both Home and Factory. Many examples. Dull, dark red or brown. Octagonal bowl and base. No decoration. Base expands slightly towards stem end. Relatively small pipe, three slightly varying sizes.

Plate 18 Q. Obtuse Angle. Both Home and Factory. Many examples. Glossy, light red to deep red. Plain round bowl and base: the base terminates in rounded and swelled end. “Hayiti” impressed on right side of base. At least three sizes of lettering. A few of these pipes are right angled. A similar pipe, except that it had one small rounded band of beading near the top of bowl, the Company called theirs “Powow Smooth Shaker”.

Plate 18 R. Very Acute Angle. Home. 10 examples. Dark, glossy red. “Genuine” is impressed on the right side of base, except one example which had no lettering. Plain round bowl and base, terminating in rounded and swelled base end. All apparently from same mold except one which was not marked “Genuine”.

Plate 18 S. Acute Angle. Both Home and Factory. Many examples. Glossy, dark red. Plain hexagonal bowl which expands towards the bottom. Plain, slim round base tapering towards stem end. These pipes usually carry a high glossy finish. Two slightly different sizes.

Plate 19 T. Slightly Acute Angle. Home. Fourteen examples. Uniform light tan color. Undecorated round bowl and base. Bowl tapers uniformly from top to bottom and base expands uniformly to stem end. Two slightly varying sizes. No mold marks, but some evidence of smoothing.

Plate 19 U. Right Angle. Home. Two examples. Uniform, light pinkish tan color. Quite similar to “T” except bowl diameter is slightly larger and does not have the extreme taper, but rounds towards the base. Two slightly varying sizes. Probably made of the same clay by the same person who made “T”. No evidence of mold marks, but some evidence of smoothing.

Plate 19 V. Acute Angle. Factory. One example. Dull red. Round bowl and base. Two bands of rounded beading encircle mid-portion of bowl, base expands towards stem end. “117” in raised figures appears on the left side of the base near stem end.

Plate 19 W. Right Angle (A Surface find). One example. Dull red. Except for its angle, this pipe is quite similar to “V” with its two bands of rounded beading encircling the bowl.

Plate 20 X. Slightly Acute Angle. Factory. One example. Salmon pink color. Ten-sided bowl and base. A rounded band of beading is near the top of bowl, the base end is simply cut off flat.

Plate 20 Y. Acute Angle. Both Home and Factory. Two examples. The bowl is decorated by narrow upright grooves and ridges which extend from the base up to and lightly across a rounded band which encircles the bowl near its top. The hexagonal base flares somewhat toward the stem end. This the Company called “Wigwam Shaker”.

Plate 20 Z. Acute Angle. Factory. Four examples. Color ranges from pale red to light orange, though two are very dark, probably from having lain long in the stream bed. The round bowl is encircled by a band of rounded beading near the top. Below this, on each side of the bowl, appears “CATLINS”. The base is hexagonal and its planes merge into the lower portions of the round bowl. The top plane of the base seems to be divided into two narrower planes which give the base a seven-sided appearance; this however is probably due to lack of trimming of the mold mark. The base terminates in a large rounded stem end. This was probably a specialty pipe, and apparently all the pipes of this form had these characteristics.

Plate 20 AA. Acute Angle. Factory. Four examples. Color ranges from pale red to light orange to medium red. The 14 upright panels which constitute the bowl, with its two encircling rounded bands near the top, give the effect of a wooden bucket whose staves are held by hoops. The raised number “103” appears on the flat bottom. In one example a metal ferrule, apparently of brass, is still in place around the stem end of base. Other examples of this pipe no longer retain the ferrule; however, the discolored pattern of the ferrule was present to show that each had originally had one in place. All pipes of this form seem identical and evidently came from the same mold.

Plate 21 AB. Right Angle. Factory. One example. Dark Red. Round undecorated bowl and base. Stem end of base has an inside taper to hold a small reed stem.

Plate 21 AC. Slight Obtuse Angle. Home. One example. Glossy, dark red. Similar to “AB” except the angle of bowl and “ORIGINAL” is impressed on the right side of the longer base.

Plate 21 AD. Obtuse Angle. Factory. One example. The plain bowl and base have a uniform high glossy red finish. “POWHATAN” is impressed on the right side of base. The stem end of base has been broken off, and it is possible that this base terminated in a clay stem which was an integral part of the pipe. In that event it would have followed the pattern of some of the old white clay imports. There are no spurs or projections of any nature at the bottom of the bowl.

Plate 21 AE. Probably Obtuse Angle. Factory. One example. Glossy medium red. This is a form similar to some early white clay imports. While the only 20 example available to us was badly broken, it seems to have its own integral clay stem, and it definitely has one spur below the bowl.

Roll of Fired Clay. A portion of a roll of fired clay was found in the fill on the Factory site. It evidently had been prepared for molding, and some clay had been broken from each end. It could have been a test firing of the clay, or the piece may have unintentionally gotten into the kiln.

Plate 22 AF. Right Angle. Factory. Two examples. Colors are light orange and red. A flat band encircles the top of the bowl, and below this is a more narrow rounded band, whose lower edge is here and there lightly cut in line with the grooves below. The vertical grooves of decoration on the bowl continue, or merge with a lesser number of horizontal grooves and ridges which run to the stem end of the base. These grooves, in part at least, extend over the large rounded swell at stem end of base. These two pipes illustrate the minor differences that may exist in different molds used in making the same basic pipe form.

This and the following three pipe forms seem to represent a transition from the earlier, rather heavy, sturdy and relatively thick side-walled clay pipes, to a pipe lighter in weight, which is more representative of the form in use by what might be considered the last generation of regular clay pipe smokers.

Plate 22 AG. Acute Angle. Factory. One example. Color is gray. This piece was among the eight pipe sherds, still sufficiently intact to give an indication of the original pipe form from which they had come, that were picked up by us on the driveway of the Pamplin Smoking Pipe and Manufacturing Company in July 1969. Some were heavily glazed and of a different character from the pipes dealt with up to this point, and seem to have come from pipes resulting from the change in style mentioned under “AF”.

This pipe fragment has some characteristics similar to “AF”. The bowl decoration towards the top is unknown, but vertical lines of decoration occupy the bowl, and only those on the front of the bowl continue along the base; those on the sides terminate upon joining the front lines. The stem end of the base is also somewhat different, being decorated by a rounded and finally a flat band. This sherd carries a moderately heavy glaze and it is the first pipe form presented which actually shows evidence of a salt glaze.

Plate 22 AH. Right Angle. Factory. One example. Color pale yellow to light brown. Round bowl and base, double rounded band of beading around top of bowl and stem end of base. Bowl decorated with raised dots in cross-hatched pattern. Spiral decoration on base. Prominent mold marks, thin sidewalls. Heavily glazed.

Plate 22 AI. Right Angle. Factory. Two examples. Color ranges from deep red through light orange to yellow. This lighter pipe with thin sidewalls has two narrow rounded bands encircling the top of bowl, which is otherwise plain. A large rounded band is at stem end of base. These pipes are well glazed.

Plate 23 AJ. Right Angle. Factory. One example. Dark Red. This is a version of the Company’s novelty “Tomahawk Pipe”, decorated to order for special 21 occasions. The pipe illustrated was made specifically for sale at the Chicago World’s Fair and has “Century of Progress, Chicago” in raised letters on the left side. “1833—(likeness of an Indian)—1933” is on the right side of bowl.

Plate 23 AK. Right Angle. Factory. One example. Color light tan. This was the Company’s standard novelty pipe, recommended for all occasions, and it was shaped like a tomahawk. A likeness of Washington appears on the right side of the bowl, with the name “Washington” in raised letters above. On the left side is the likeness of an Indian wearing a Plains headdress, and above it in raised letters is the name “Powhatan”. A wide flat band encircles the stem end of base.

The Pamplin Company’s literature stated, Tomahawk Pipe-Novelty, molded from hand engraved brass die, of finest clay, hard-burned and glazed. An attractive item for carnivals, conventions, fairs, etc. Packed 200 to a box with 5″ reed stems. Price $13.50 per box. This pipe was a regular sales item for festive occasions (Plate 11).

Plate 23 AL. Right Angle. (A surface find). One example. Deep red. Most Pamplin pipes of home manufacture were made by women; however, Miss Wilsie Thornton and Dr. C. G. O’Brien said that a Mr. Rodgers, about 1938, made pipe molds and pipes of unusual form as a hobby. Miss Thornton mentioned two forms that he made—an Indian Head, and a Woman’s Leg, the calf being the bowl and the foot being the base, with the toes at the stem end of base. This pipe is credited locally as being of his manufacture.

Plate 23 AM. Right Angle. Home. Two examples. Deep glossy red. The decoration on the lower portion of the round and expanding bowl reminds one somewhat of a peach seed; this decoration is separated from the upper part of the plain upper bowl by a rounded band. The base is undecorated, and terminates in a smooth enlarged stem end. The second pipe of this form was a surface find.

If the Factory had Nos. 103 and 117 how many more numbers may they have had?

Impressed identifications, usually put on the base of the pipe with a stamp after the pipe came from the mold, appear on pipes from both the Homes and from the Factory. It is of interest that apparently identifications in raised lettering came only from the Factory.

In the beginning of this effort we had assumed that the pipes made by the Factory would be quite different, in both form and decoration, from those made in the homes. We have found that this assumption is not valid.

There is a great deal of overlapping, probably due to the Factory, after its arrival in Pamplin, taking over and producing a number of the shapes and designs that had long been in use in the Home Industry. It is also possible that the Home Industry appropriated some of the Factory pipe forms.

In addition, all local evidence agrees that the Thornton Store did not purchase 22 pipes from the Factory; they were getting plenty themselves, taken in trade for their merchandise, and which they would have to dispose of on the wholesale market in competition with the Factory.

There is local evidence that the Factory did, at times, buy locally made pipes in order to fill large orders, as well as when their machinery was not in operation. It is quite unlikely however, after buying and paying for them, that these pipes would be found in the landfill on the Factory grounds, the fill from which the “factory” pipes considered in this study came.

Of the total of 39 pipe forms located by us, 10 were from Home Industry, 19 from the Factory, (eight appeared in both), and two were either surface finds or the knowledge of their exact place of manufacture lost, as they had long been in the hands of their local Pamplin area owners.

The Akron Company had made pipes before they established the pipe plant at Pamplin, and the names of some of their pipes in the Pamplin literature would infer that at least one form, the “Akron Hamburg”, had been carried from Akron to Pamplin, which then is described as “from Virginia clay, attractive red color”.

On the other hand, Mrs. Betty Price has been quoted as saying that the pipe form known as “Hamburg” was one of the first made by the women of the area.

For a time in later years, at least by 1941, the Pamplin Factory made a pipe similar in form and decoration to their “Akron Hamburg”, but of fire clay, and called it “Akron Shaker”.

Since there is so much overlapping of form and decoration between the pipes made in the homes and those made by the Company, one wonders if there might not have been even more overlapping had the sample available to us at this late date been greater than the 4,451 pipes examined.

It is our conclusion that when the Akron Company came to Pamplin they started to produce pipes of a number of forms that had long been made by the Home Industry of the Pamplin area. They may also have brought one or more Akron pipe forms and decorations with them, to be manufactured at Pamplin. In turn the Pamplin Home Industry possibly adopted some forms now being produced by the Company. (Some of these forms may also have been in production in other areas, but probably of different clay).

The foremost factor distinguishing Pamplin area pipes, from either manufacturing source, was the “Virginia clay, of attractive red color”.

So far as we have been able to determine, no particular friction ever developed between the Factory and the industry being carried on at the homes; each had its own wholesale outlets.

To the best of our knowledge, the Home Industry started about 1740 and definitely closed in 1953.

The Pamplin Smoking Pipe and Manufacturing Company was established about 1878, and it definitely closed in 1951.

In our work we have handled literally hundreds of the pipes, Plate 13 A, called “Powhatan Original” in the Company’s literature and advertising. These had been excavated both from the factory grounds and from the basement of the old Thornton Store, and we found nothing about these two lots of pipes that would seem to distinguish the two manufacturing sources. Of the total, only one single pipe failed to carry the word “Original” impressed in the base.

This “Original” was an early Home Industry form, and there is strong evidence that when the Company came to Pamplin they adopted this form, and added “Powhatan” in their advertising, just as they must have adopted some other local pipe forms. “Original” was also impressed, but probably at a still later date, on the base of three other pipe forms; they were forms “B”, “M”, and “AC”.

We also believe that the Company made the best estimate as to the starting date of the home pipemaking industry, (they would have had about a hundred year advantage in arriving at such a date, as compared to the problem under present circumstances), and applied that date to Pamplin Smoking Pipe and Manufacturing Company as having been “established 1739”. In other words, they pictured themselves as being a continuation of the industry that was already there.

If the date of 1878, or one near that time, for the establishment of the Pamplin Smoking Pipe and Manufacturing Co. is correct, then this is later than the terminal date of some of the western forts and trading posts at which Pamplin pipes have been reported. It would therefore seem evident that the Pamplin pipes found in some western locations were the result of Home Industry, made before the pipe plant ever got to Pamplin. This is authenticated by the fact that they were being carried by the Bertrand.

It would seem desirable, instead of considering these pipes as Pamplin Company products, to simply think of them as Pamplin Area Pipes.

| 1935 | Farmville Herald, Farmville, Va. Mar. 29, 1935 “Pamplin Pipe Factory” |

| 1946 | Times-Dispatch, Richmond, Va. April 21, 1946 “Indian Pipes are Still Produced from Clay Found in Virginia”. |

| 1965 | Times-Dispatch, Richmond, Va. March 31, 1965 “Pamplin Pipes in Smithsonian”. |

| ? | Times-Dispatch, Richmond, Va. March 30 ? “Historic Pipes Shipped West From Virginia”. |

| 1962 | Times-Virginian, Appomattox, Va. “Ramblings About Clay Pipes” Oct. 18, ’62 |

Plate 1. Tools of the Home Pipemaking Industry. Drawing, Edward F. Heite, Virginia Historic Landmarks Commission.

Plate 2. Pamplin Pipe, from the Bertrand, sunk in the Missouri River, April 1, 1865. Photos, Ronald R. Switzer, Bertrand Conservation Laboratory, National Park Service.

Plate 3. Stencils on Box of Pamplin Pipes retrieved from the Bertrand. The box top carried the name and address of the Consignee. One end evidently identified the shipment. The Consignor was identified on one end and on both sides of the box. Copies, Ronald R. Switzer, Bertrand Conservation Laboratory, National Park Service.

Plate 4. The Pamplin Smoking Pipe and Manufacturing Company, Inc., March 1965. Photo, Richmond Times-Dispatch.

Plate 5. Kiln of the Pamplin Smoking Pipe and Manufacturing Company, Inc., March 1965. The kiln had a capacity of 200,000 pipes at a single burning. Photo, Richmond Times-Dispatch.

Plate 6. Pipe Molding Machine from the Pamplin Factory. Photos, Virginia Historic Landmarks Commission.

The machine.

Detail of mold.

Plate 7. Saggers Used by the Pamplin Factory. Dimensions of the larger sagger,—overall height 6″, overall width, 10¼ to 10½″, wall thickness ⅞ to 1″. Dark Brown glaze, mottled. Photos and description, Edward A Chappell, Virginia Historic Landmarks Commission.

Plate 8. Brochure, Pamplin Smoking Pipe and Manufacturing Co., Inc., 1941. Copy, Morton L. Wallerstein.

This is the largest plant in the world devoted exclusively to the manufacture of Indian stone clay pipes. Our plant has a capacity of 25,000 pipes per day; our kiln has a capacity of 200,000 pipes at a single burning.

From careful search of the records, this factory started more than 200 years ago. The present plant has been in operation for 44 years. Skilled American labor is used in a modern, day-lit plant with special attention to cleanliness, sanitation and ideal conditions.

The buying trend is toward Indian clay and stone pipes. Tourists and visitors to your locality are buying them as gifts, souvenirs and for personal use. Every true American wants a genuine Indian pipe—and can buy one, for little more than the cost of a can of smoking tobacco.

Order your assortment today. Display them well and they will sell quickly. Pamplin Indian Pipes give you a profit unheard of in the tobacco trade.

PAMPLIN SMOKING PIPE AND MANUFACTURING CO., Inc.

Established 1739

Manufacturers of All Styles of

Stone and Powhatan Clay Pipes and Reed Stems

PAMPLIN, VIRGINIA, U. S. A.

Printed in U. S. A.

Hand-Made “Powhatan”

Powhatan

INDIAN CLAY PIPES

MILD

mellow

SWEET

PURE

50¢ WITH Two STEMS

Be A Modern Indian Chief!

Smoke the Genuine

“Powhatan” pipe

MADE IN VIRGINIA BY NATIVES OF VIRGINIA

This handsome display card, in five colors, given with each order for five dozen “Powhatan” Hand-Made Pipes, makes selling easy. Order yours.

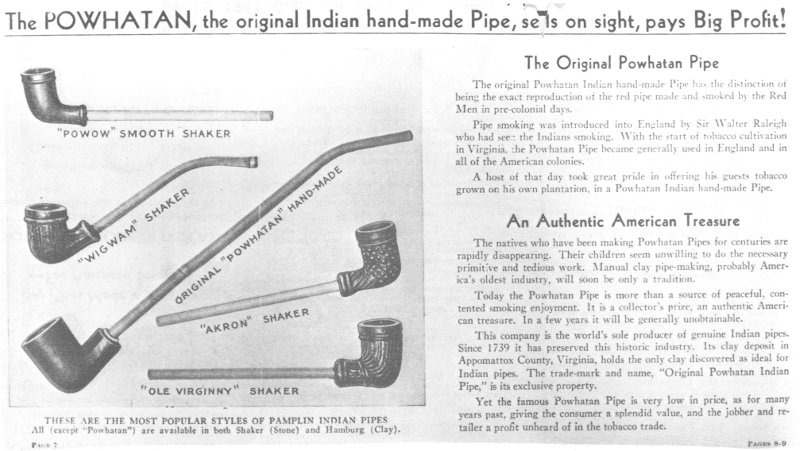

Plate 9. The “Original” Powhatan and other Pamplin Pipe forms. Brochure, 1941. Copy, Morton L. Wallenstein.

The POWHATAN, the original Indian hand-made Pipe, sells on sight, pays Big Profit!

“POWOW” SMOOTH SHAKER

“WIGWAM” SHAKER

ORIGINAL “POWHATAN” HAND-MADE

“AKRON” SHAKER

“OLE VIRGINNY” SHAKER

THESE ARE THE MOST POPULAR STYLES OF PAMPLIN INDIAN PIPES All (except “Powhatan”) are available in both Shaker (Stone) and Hamburg (Clay).

The Original Powhatan Pipe

The original Powhatan Indian hand-made Pipe has the distinction of being the exact reproduction of the real pipe made and smoked by the Red Men in pre-colonial days.

Pipe smoking was introduced into England by Sir Walter Raleigh who had seen the Indians smoking. With the start of tobacco cultivation in Virginia, the Powhatan Pipe became generally used in England and in all of the American colonies.

A host of that day took great pride in offering his guests tobacco grown on his own plantation, in a Powhatan Indian hand-made Pipe.

An Authentic American Treasure

The natives who have been making Powhatan Pipes for centuries are rapidly disappearing. Their children seem unwilling to do the necessary primitive and tedious work. Manual clay pipe-making, probably America’s oldest industry, will soon be only a tradition.

Today the Powhatan Pipe is more than a source of peaceful, contented smoking enjoyment. It is a collector’s prize, an authentic American treasure. In a few years it will be generally unobtainable.

This company is the world’s sole producer of genuine Indian pipes. Since 1739 it has preserved this historic industry. Its clay deposit in Appomattox County, Virginia, holds the only clay discovered as ideal for Indian pipes. The trade-mark and name, “Original Powhatan Indian Pipe,” is its exclusive property.

Yet the famous Powhatan Pipe is very low in price, as for many years past, giving the consumer a splendid value, and the jobber and retailer a profit unheard of in the tobacco trade.

Plate 10. Price list of Pamplin Company Pipe Forms. Brochure, November 15, 1941. Copy, Morton L. Wallenstein.

PRICE LIST

(EFFECTIVE NOVEMBER 15, 1941)

[See Page 6 for Jobber’s Discounts]

POWHATAN HAND-MADE PIPES

Individually packaged in attractive rustic container, Historical Booklet, instruction tag, and two 10″ reed stems—one curved, one straight, ready for mailing.

Gross $48.00

Minimum order ¼ Gross

Retails for from 50¢ to $1.00

Buy Pipes Made in America—For American Smokers!

POWHATAN COUNTER DISPLAY

Twelve Powhatan Pipes, each with Historical Booklet, instruction tag, and extra 10″ straight stem included.

DOZEN TO DISPLAY CARD

Gross $48.00

Minimum order ¼ Gross.

(Display card illustrated on Page 3 of this Catalog.)

Page 10

Powhatan Machine-Made

Machine-made Powhatan, fitted with cork closures and 10″ reed stems, bowls trade-marked. Packed 50 to the box with stems. 25¢ Retailer. Price, $4.00 per box.

Akron Shaker

Machine moulded from fire clay, hard-burned and glazed; a stone pipe fitted with 5″ reed stem. Packed 100 to a box with stems. 15¢ Retailer. Price, $3.00 per box.

Powow Shaker

Stone pipe, smooth finish, glazed, fitted with 5″ reed stem. Packed 100 to a box with stems. 15¢ Retailer. Price, $3.00 per box.

Ole Virginny Shaker

Heavier stone pipe, attractive finish, fitted with 5″ reed stem. Packed 100 to box with stems. 15¢ Retailer. Price, $3.00 per box.

Wigwam Shaker.

Real character distinguishes this attractive stone pipe, fitted with 5″ reed stem. Packed 100 to box with stems. 15¢ Retailer. Price, $3.00 per box.

Shaker Assortment.

An assortment of 25 each of the four above described stone pipes, 100 pipes, fitted with 5″ reed stem. Packed 100 to box. 15¢ Retailer. Price, $3.50 per box.

Stems can be furnished straight or bent. Additional Stems and Stems Extra Length Can Be Supplied at Slight Extra Cost.

Send Money Order or Check with Order to Save Time.

Terms: 20% Cash With Order. Net 30 Days.

Page 11

Akron Hamburg

(Similar to Akron Shaker)

Machine-made from Virginia Clay, hard-burned, attractive red color. Also made in white. Packed 100 to box with 5″ reed stems. 10¢ Retailer. Price, $2.50 per box.

Powow Hamburg

(Similar to Powow Shaker)

Machine-made from Virginia Clay, hard-burned, an attractive small bowl. Packed 100 to box with 5″ reed stems. 10¢ Retailer. Price, $2.50 per box.

Ole Virginny Hamburg

(Similar to Ole Virginny Shaker)

Machine-made from finest fire-clay, hard-burned, white, simulates meerschaum, one of the most popular shapes. Also made in red. Packed 100 to box with 5″ reed stems. 10¢ Retailer. Price, $2.70 per box.

Wigwam Hamburg

(Similar to Wigwam Shaker)

Machine-made from Virginia Clay, hard-burned. Choice of red or white. Shape appeals to young and old. Packed 100 to box with 5″ reed stems. 10¢ Retailer. Price, $2.70 per box.

Hamburg Assortment

An assortment of 25 each of the four above described clay pipes, 100 pipes, fitted with 5″ reed stems. Packed 100 to box with stems. 15¢ Retailer. Price, $2.85 per box.

Stems can be furnished straight or bent. Additional Stems and Stems Extra Length Can Be Supplied at Slight Extra Cost.

Send Money Order or Check with Order to Save Time.

Terms: 20% Cash With Order. Net 30 Days.

Page 12

Plate 11. “Tomahawk Pipe”—A Real Novelty, and Jobber’s Discounts. Brochure, 1941. Copy, Morton L. Wallerstein.

The Tomahawk Pipe—A Real Novelty

Moulded from hand-engraved brass die, of finest quality fire clay, hard-burned and glazed. An attractive item for carnivals, conventions, fairs, club meetings, etc. Packed 200 to box, with 5″ reed stems. Price, $13.50 per box.

To the Trade

| JOBBER’S DISCOUNTS | |

|---|---|

| Apply ONLY When Whole Order Is Shipped At SAME Time | |

| 10 to 20 Boxes | 20% |

| 21 to 40 Boxes | 25% |

| 41 to 100 Boxes | 30% |

| 101 to 500 Boxes | 35% |

In addition to the 10 styles of Indian Pipes illustrated and quoted in this folder, we make many other styles of Indian Clay and Stone Pipes. Orders for additional designs—for Advertising, Souvenirs, Gifts, Tourists, Fairs, Exhibitions, and Special Purposes—are solicited. We can make any style of pipe that can be made from either Virginia Red Clay or Fire Clay. Our own designers and artists are at your service. We invite your inquiries. Samples will be mailed promptly to rated firms.

(Note: If you have a friend to whom you would like for us to send one of these folders, please write. It will be sent promptly.)

Plate 12. Sales Tag, carried by the “Original” Powhatan Pipe, 1941. Copy, Morton L. Wallerstein.

This Is An

“Original”

Powhatan Pipe

Made entirely by hand in a primitive way, from hand-carved moulds several centuries old, by natives in Appomattox County, Va. Succeeding generations, dating back to the earliest days of America, have practiced the ancient art of making these Indian pipes by hand. The slow, tedious work, requiring innate skill, is not attractive to the moderns. This art is rapidly disappearing. Soon the genuine Powhatan Pipe will be generally unobtainable. This Pipe, therefore, will become a rare and cherished antique and keepsake.

This Powhatan Pipe is an original, made exactly like those the Indians used prior to the coming of the white man to America, and as smoked in the early colonies and in England following Sir Walter Raleigh’s introduction of tobacco into that country. The clay is porous and the old Virginia reed stem also absorbs the nicotine. To clean the pipe according to the old Virginia method, remove the stem and place the bowl into the fire-place. This will burn out the absorbed nicotine without in any way harming the pipe. New stems may be obtained from your tobacconist.

PAMPLIN INDIAN PIPE CO.,

Pamplin, Va., U. S. A.

Plate 13. Pamplin Area Pipe Forms.

Plate 14. Pamplin Area Pipe Forms.

Plate 15. Pamplin Area Pipe Forms.

Plate 16. Pamplin Area Pipe Forms.

Plate 17. Pamplin Area Pipe Forms.

Plate 18. Pamplin Area Pipe Forms.

Plate 19. Pamplin Area Pipe Forms.

Plate 20. Pamplin Area Pipe Forms.

Plate 21. Pamplin Area Pipe Forms.

Plate 22. Pamplin Area Pipe Forms.

Plate 23. Pamplin Area Pipe Forms.

by

Patricia J. O’Brien and Kevin Hart

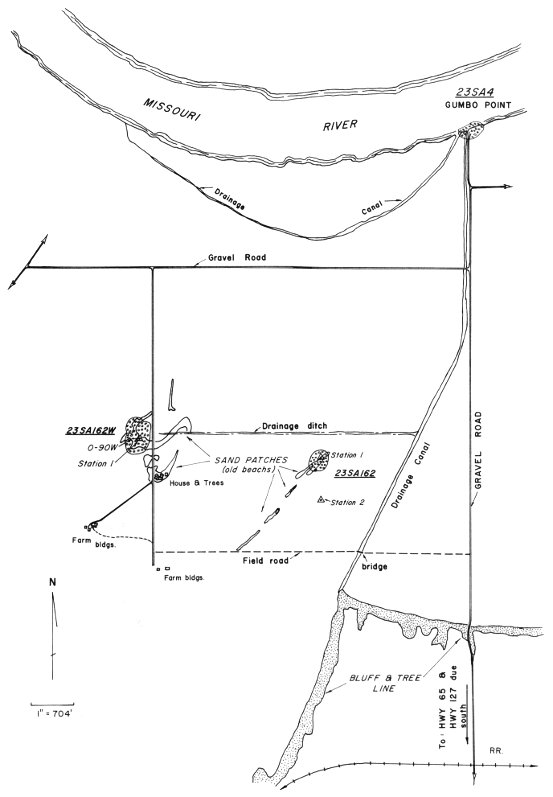

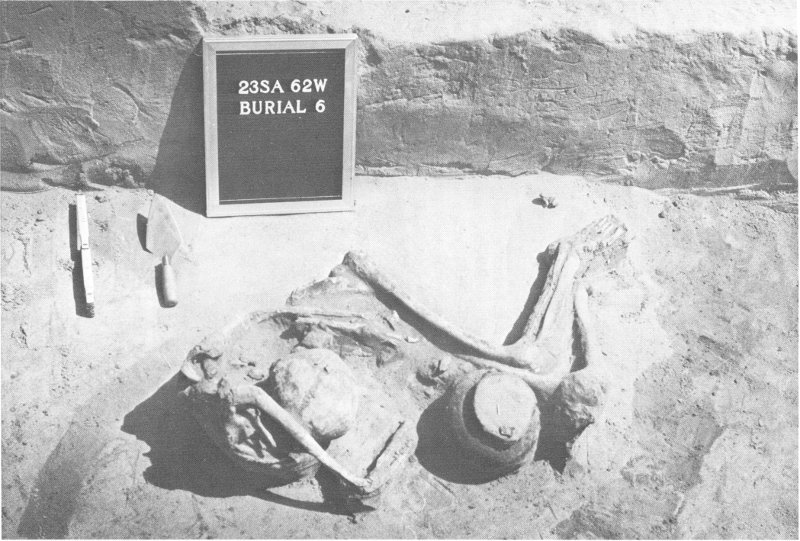

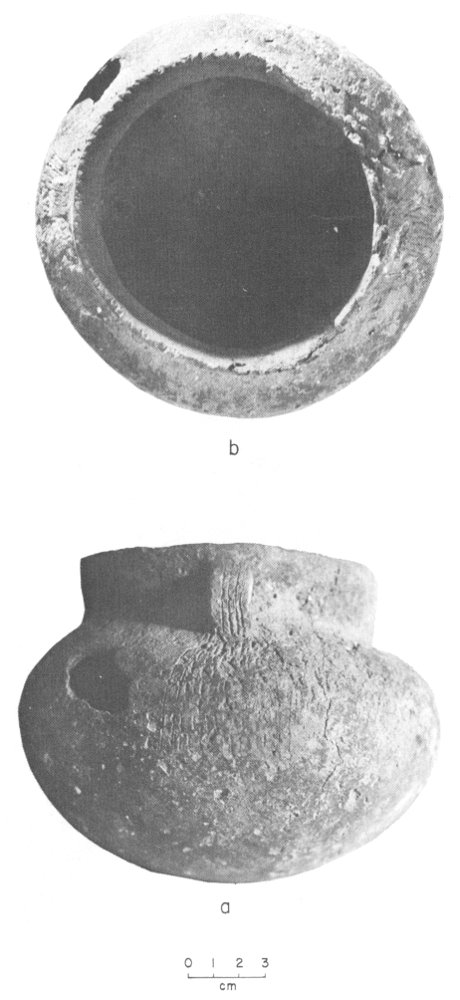

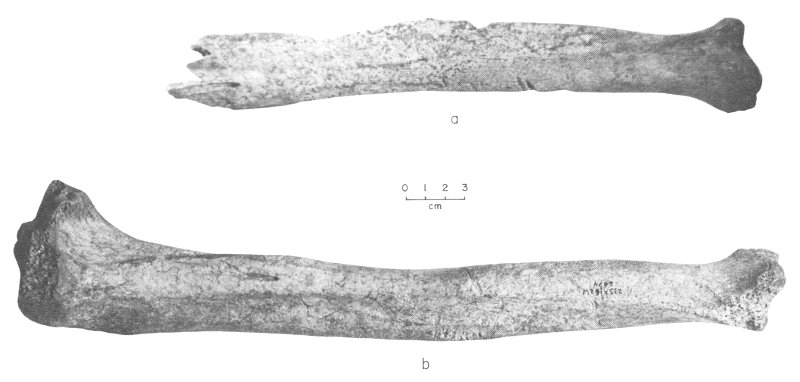

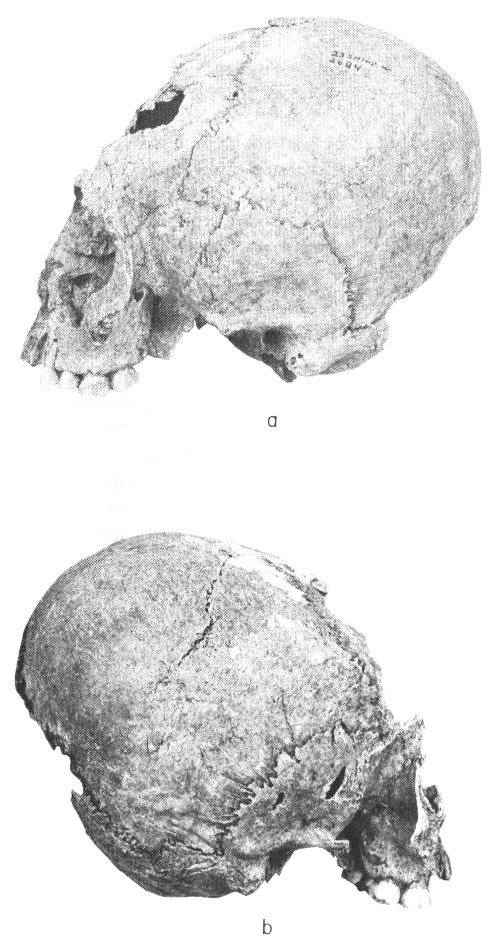

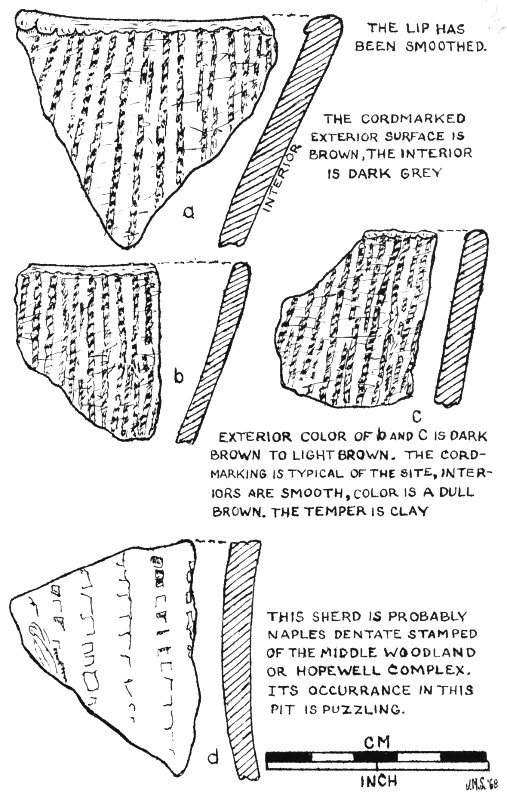

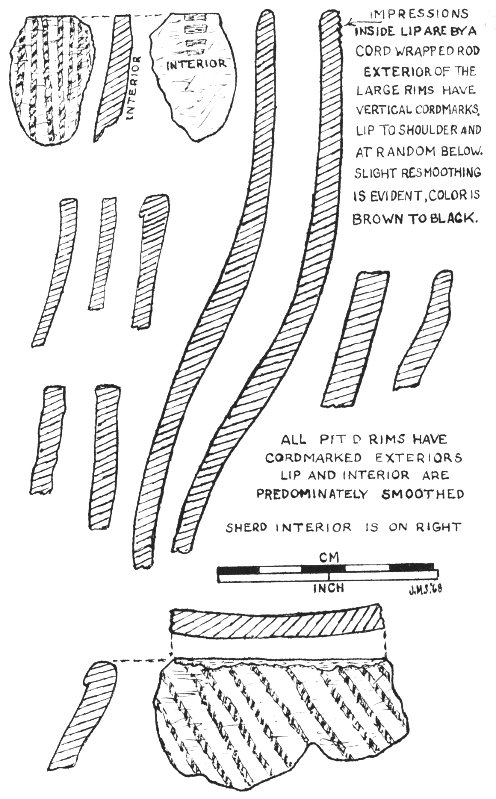

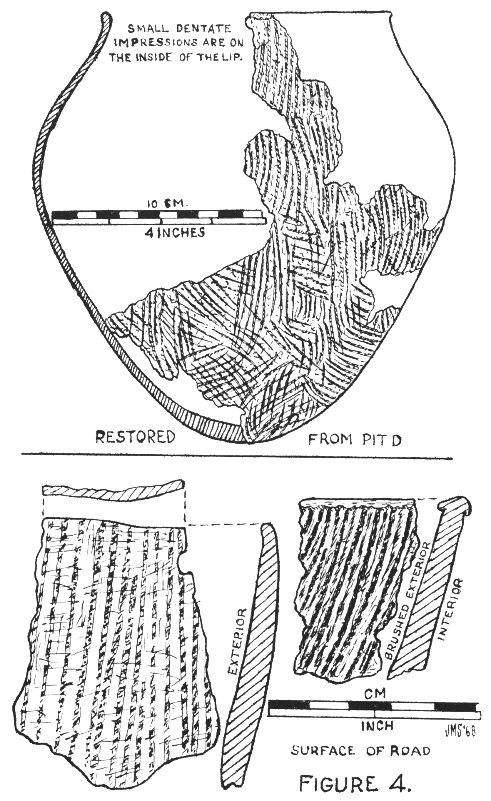

The Utlaut site (23SA162W) is located on the floodplain of the Missouri River about one mile west of Malta Bend, Saline County, Missouri and approximately two miles northwest of the junction of Highway 65 and 127.

The site is situated on land owned by Oscar John of Sweet Springs, Missouri and was farmed by Ryland Utlaut of Grand Pass. Both kindly allowed us to excavate there. We were directed to the site by J. M. “Buster” Crick of Corder, Missouri, a local collector who had been finding ceramics which looked “Mississippian.” His aid was invaluable, for without it this work could not have been done.

Scattered occupational debris was found covering an area ca. 100 feet in diameter around our test, but the major materials recovered, in six burials, seem not to be related to the surface debris. Those materials will be reported in a later paper dealing with site 23SA162, the Cole Lake Sand Ridge site.

As mentioned, the Utlaut site is situated on the floodplain of the river. The area, though, is in reality an old beach of the Missouri, formed when the river swung south of its present course and came near Grand Pass. Because the soil was almost pure sand, all of it was screened.

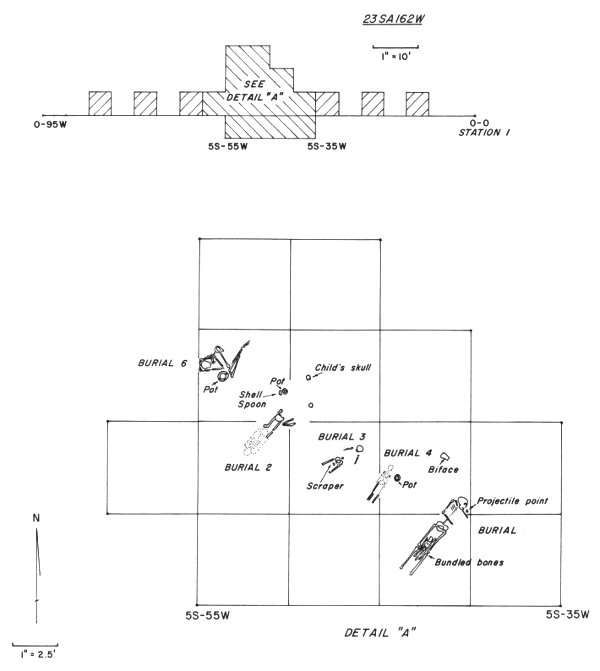

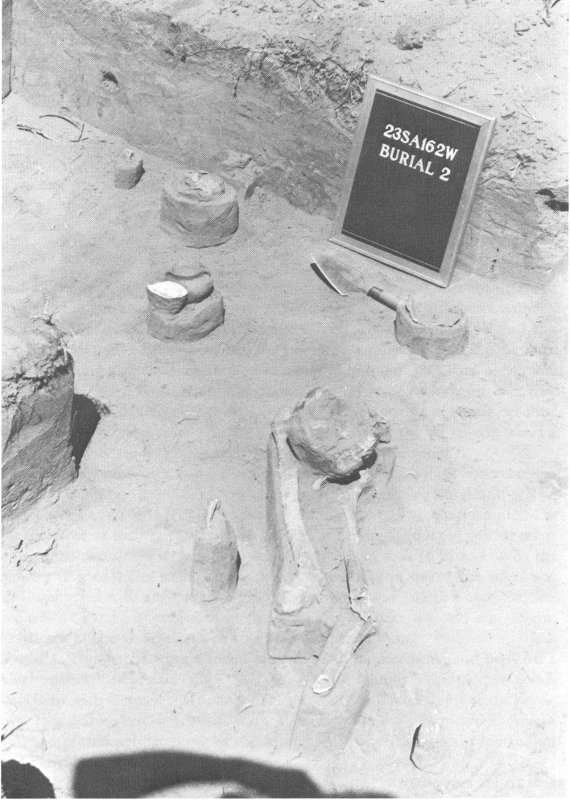

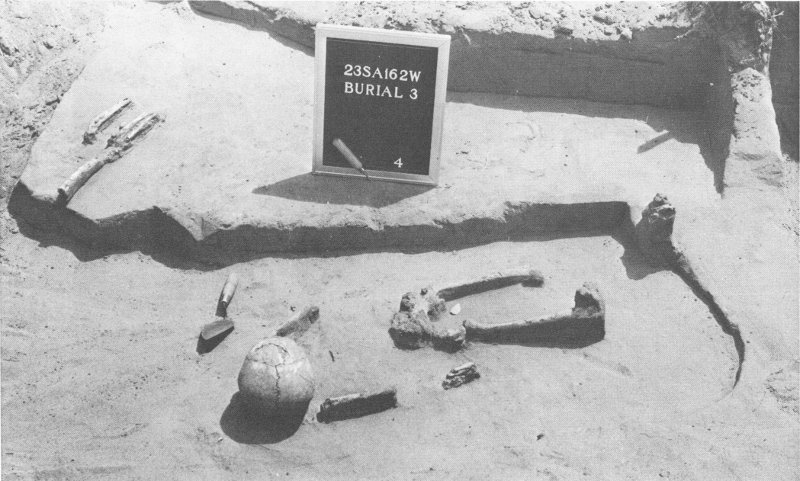

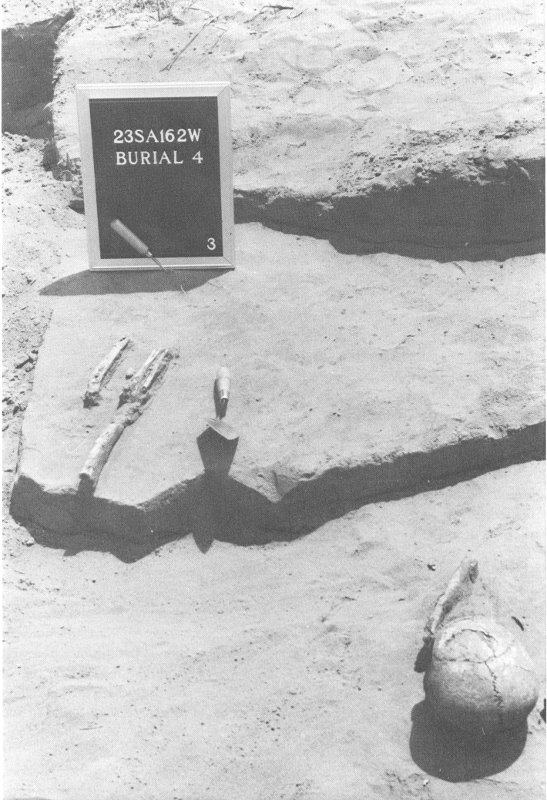

The initial test was an east-west trench comprising five alternating squares (Fig. 2). Burial materials were found between stakes 35W and 55W north and south of the 0 line (Fig. 2). Remains of five burials were recovered. While a few bones were treated as a separate burial in the field (Burial 5), they were found to be related to Burial 2 on completion of the analysis. The bones in burials 1 through 5 were in very poor condition, and because of cultivation many are missing.

The osteological analysis of the skeletal remains found in Appendix I is by the junior author and Clark Larsen. The descriptions to follow will focus on the cultural nature of the burials.