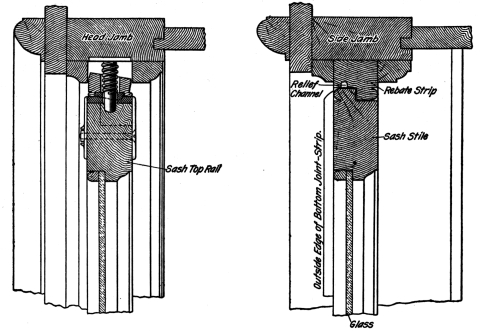

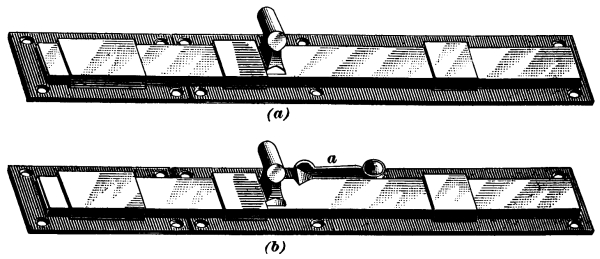

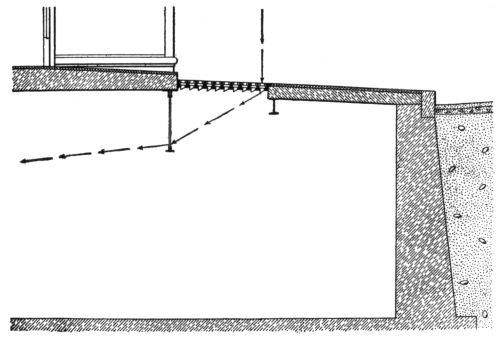

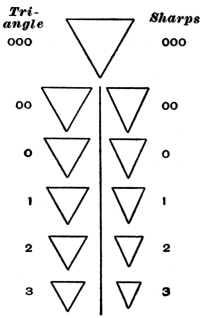

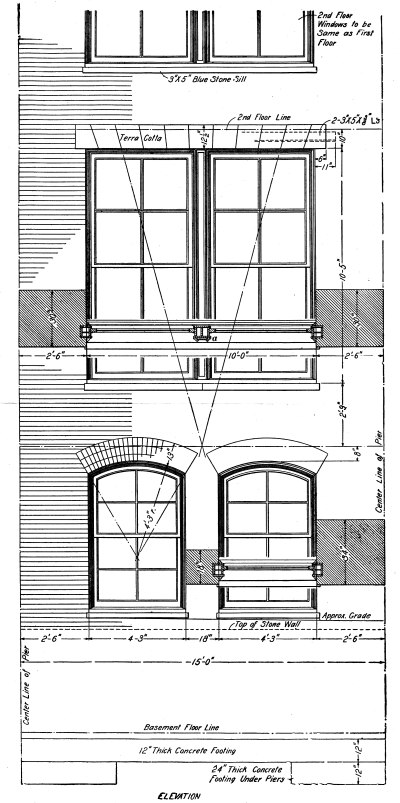

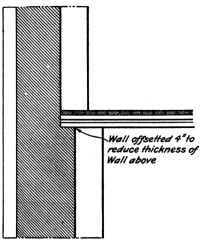

Fig. 1

International Library of Technology

333

223 Illustrations

Prepared Under Supervision of

W. S. LOWNDES, Ph. B.

DIRECTOR, SCHOOLS OF ARCHITECTURE

AND BUILDING CONSTRUCTION

INTERNATIONAL CORRESPONDENCE SCHOOLS

BUILDERS’ HARDWARE

ESTIMATING AND CALCULATING

QUANTITIES

MILL DESIGN

Published by

INTERNATIONAL TEXTBOOK COMPANY

SCRANTON, PA.

1925

Builders’ Hardware: Copyright, 1908,

by International Textbook Company.

Entered at Stationers’ Hall, London.

Estimating and Calculating Quantities, Part 1:

Copyright, 1899, by The Colliery Engineer Company.

Copyright, 1908, by International Textbook Company.

Entered at Stationers’ Hall, London.

Estimating and Calculating Quantities, Part 2:

Copyright, 1899, by The Colliery Engineer Company.

Copyright, 1909, by International Textbook Company.

Entered at Stationers’ Hall, London.

Mill Design: Copyright, 1907,

by International Textbook Company.

Entered at Stationers’ Hall, London.

All rights reserved

Printed in U. S. A.

Press of

International Textbook Company

Scranton, Pa.

The volumes of the International Library of Technology are made up of Instruction Papers, or Sections, comprising the various courses of instruction for students of the International Correspondence Schools. The original manuscripts are prepared by persons thoroughly qualified both technically and by experience to write with authority, and in many cases they are regularly employed elsewhere in practical work as experts. The manuscripts are then carefully edited to make them suitable for correspondence instruction. The Instruction Papers are written clearly and in the simplest language possible, so as to make them readily understood by all students. Necessary technical expressions are clearly explained when introduced.

The great majority of our students wish to prepare themselves for advancement in their vocations or to qualify for more congenial occupations. Usually they are employed and able to devote only a few hours a day to study. Therefore every effort must be made to give them practical and accurate information in clear and concise form and to make this information include all of the essentials but none of the non-essentials. To make the text clear, illustrations are used freely. These illustrations are especially made by our own Illustrating Department in order to adapt them fully to the requirements of the text.

In the table of contents that immediately follows are given the titles of the Sections included in this volume, and under each title are listed the main topics discussed. At the end of the volume will be found a complete index, so that any subject treated can be quickly found.

| Builders’ Hardware | Section | Page |

| Staple Hardware | 55 | 1 |

| Cut and Wire Nails | 55 | 2 |

| Wood Screws, Expansion and Special Bolts | 55 | 11 |

| Sash Weights | 55 | 18 |

| Finishing Hardware | 55 | 20 |

| Metals and Their Manipulation | 55 | 20 |

| Hinges, Hinge Butts, and Special Hinges | 55 | 24 |

| Locks and Their Appurtenances | 55 | 55 |

| Window and Sash Hardware | 55 | 77 |

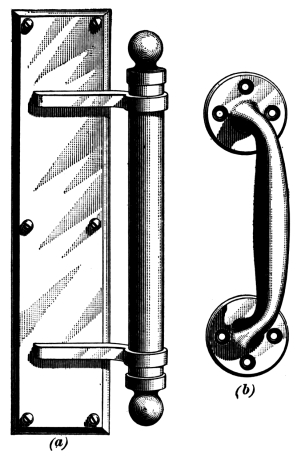

| Door Hardware and its Application | 55 | 102 |

| Shutter Hardware | 55 | 129 |

| Cabinet Trim | 55 | 132 |

| Design and Specification of Hardware for Buildings | 55 | 138 |

| Hardware of Special Design | 55 | 138 |

| Selection, Estimation, and Application of Hardware | 55 | 146 |

| Schedules and Drawings for the Hardware Contractor | 55 | 154 |

| Glass and Glazing | 55 | 157 |

| Estimating and Calculating Quantities |

||

| Scope of Subject | 60 | 1 |

| Approximate Estimating | 60 | 3 |

| Accurate Estimating Schedule | 60 | 5 |

| Excavation | 60 | 11 |

| Concrete Work | 60 | 18 |

| Masonry | 60 | 24 |

| Brickwork | 60 | 31 |

| Carpentry | 60 | 38 |

| Roofing | 60 | 46 |

| Plastering | 60 | 58 |

| Joinery | 60 | 61 |

| Structural Steel | 60 | 69 |

| Heating and Ventilating System | 60 | 69 |

| Plumbing and Gas-Fitting | 60 | 70 |

| Painting and Papering | 60 | 72 |

| Glazing | 60 | 78 |

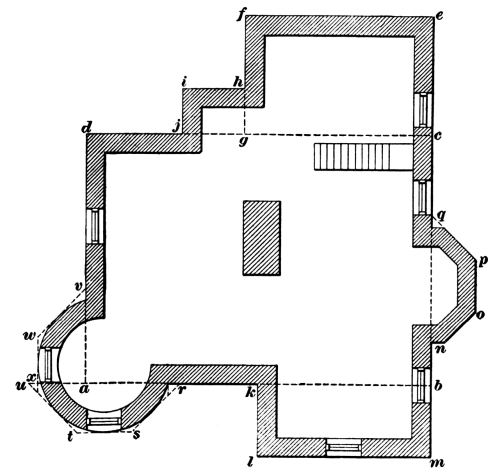

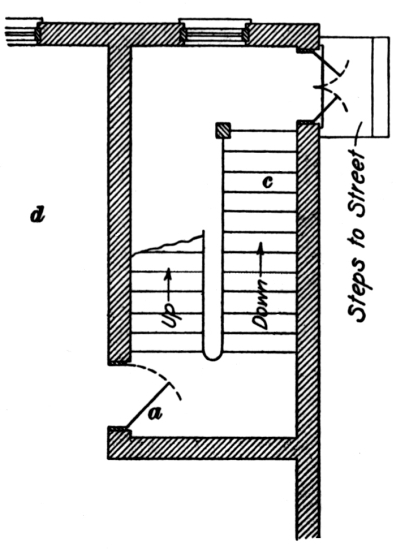

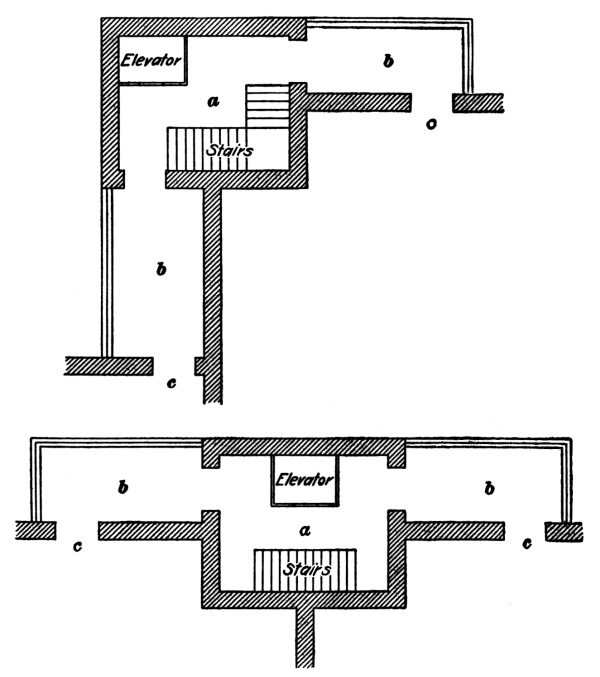

| Example in Estimating | 61 | 1 |

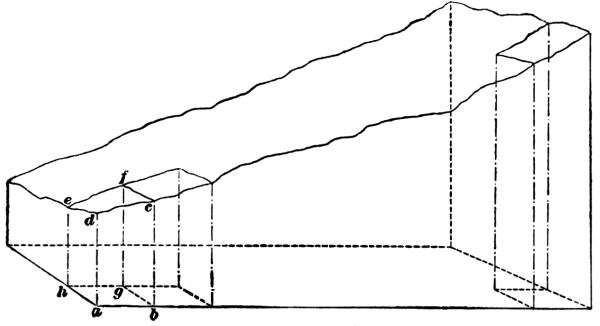

| Excavation | 61 | 2 |

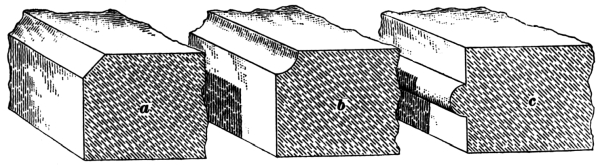

| Stonework | 61 | 4 |

| Brickwork | 61 | 8 |

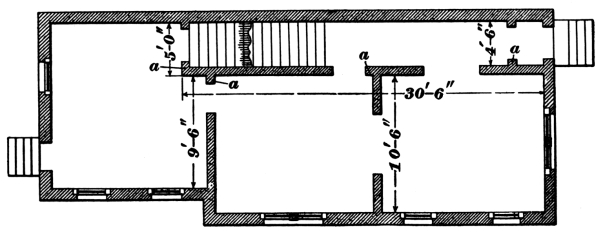

| Carpentry | 61 | 10 |

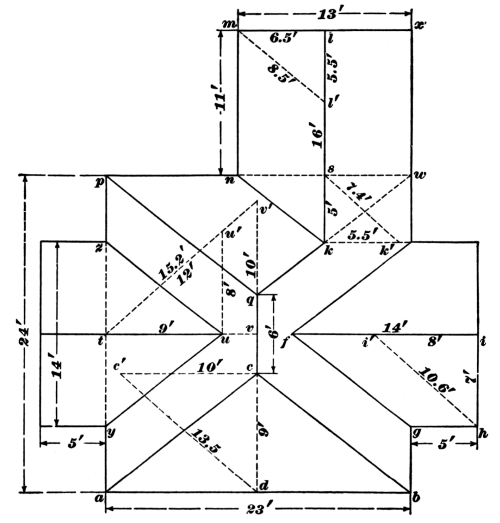

| Roofing | 61 | 21 |

| Lathing and Plastering | 61 | 22 |

| Joinery | 61 | 23 |

| Hardware | 61 | 33 |

| Heating and Ventilating System | 61 | 35 |

| Plumbing | 61 | 37 |

| Gas-Fitting | 61 | 40 |

| Wiring | 61 | 41 |

| Painting | 61 | 42 |

| Summary of Cost of Building | 61 | 44 |

| Mill Design |

||

| Site and Arrangement | 64 | 1 |

| Preliminary Considerations | 64 | 1 |

| Types of Mill Construction | 64 | 13 |

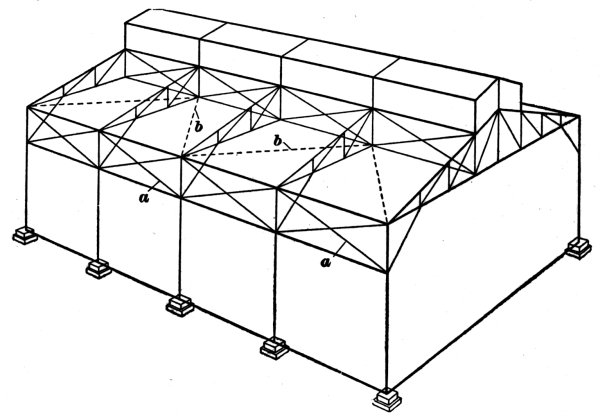

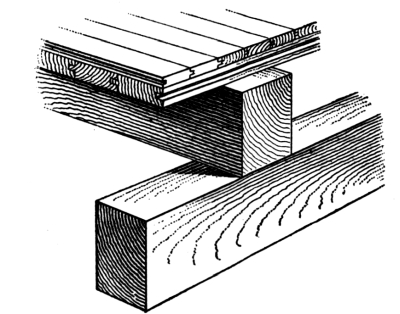

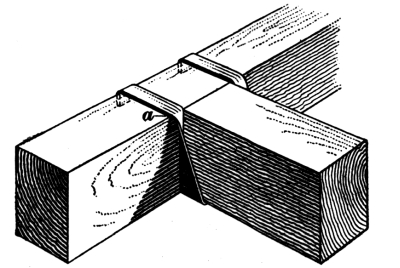

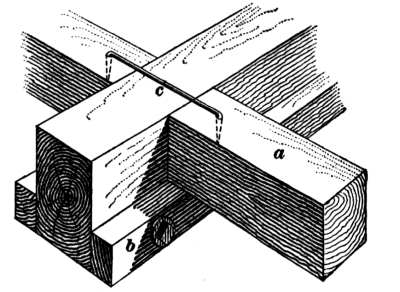

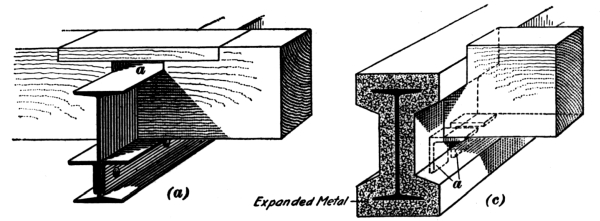

| Girder and Plank-on-Edge Construction | 64 | 13 |

| Standard Slow-Burning Construction | 64 | 18 |

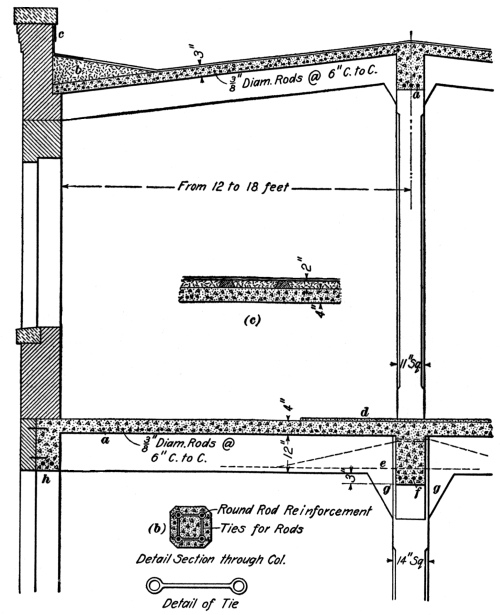

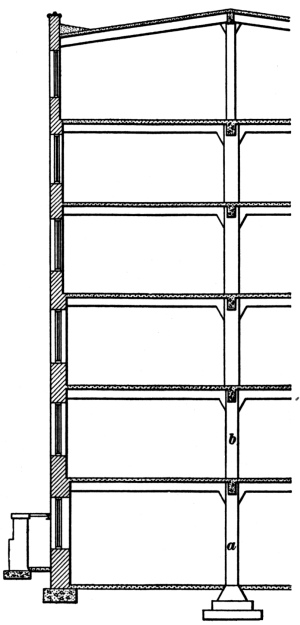

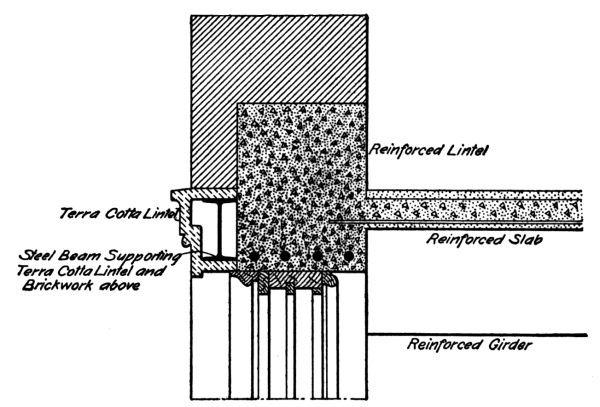

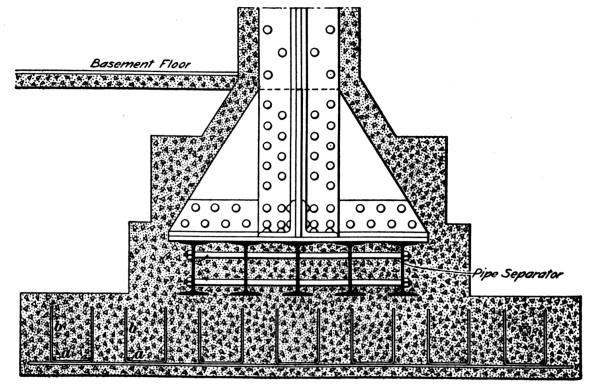

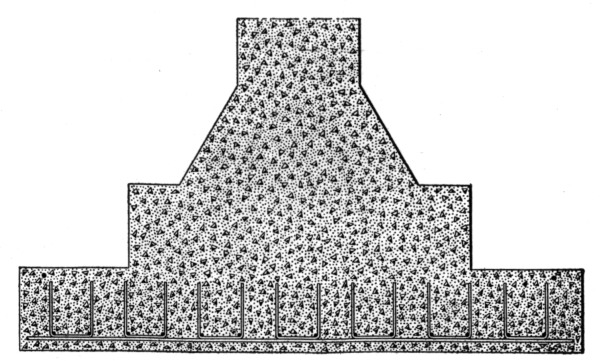

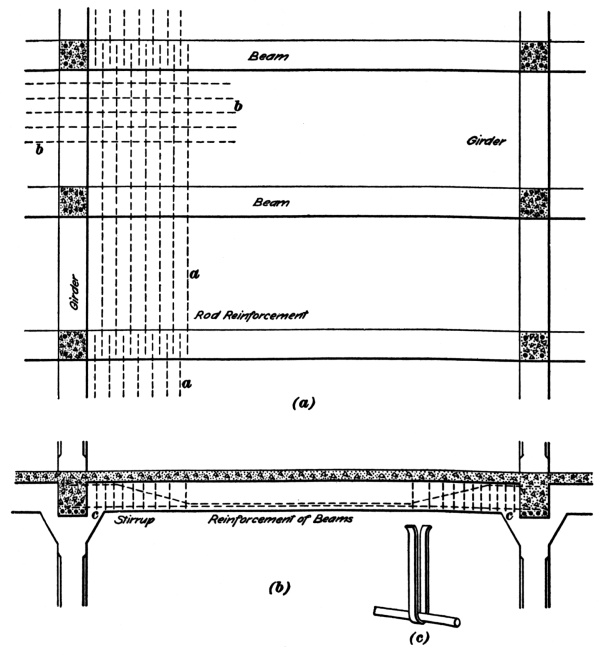

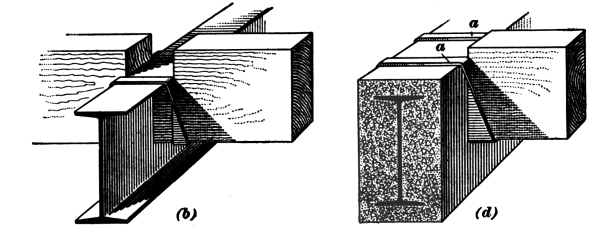

| Factory Buildings of Reinforced Concrete | 64 | 23 |

| Steel-Frame Mill Buildings | 64 | 31 |

| Details of Mill Construction and Design | 64 | 34 |

| The Power Plant | 64 | 41 |

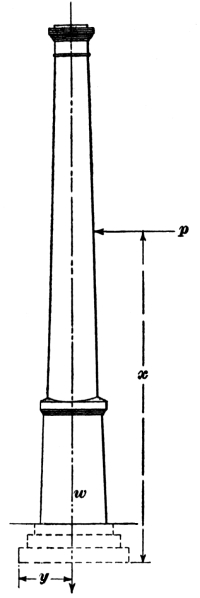

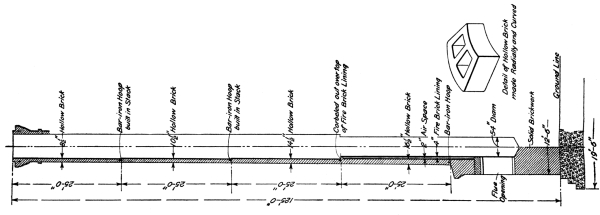

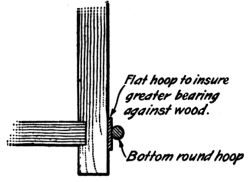

| Chimneys | 64 | 45 |

| Fire-Protection of Mill Buildings | 64 | 50 |

| INDEX | i | |

INTRODUCTION

1. The hardware used in building construction may be classified as staple and finished. Staple hardware may be considered as including such materials as nails and spikes, bolts and screws, sash weights, and other materials of this character, while finished hardware may include such devices and appliances as locks and latches, hinges, door and window trimmings, and the various metallic fixtures used in equipping the different classes of buildings. To this last classification the term builders’ hardware is frequently applied.

Strictly speaking, glass cannot be considered as hardware; nevertheless, it is frequently supplied to the builder through hardware supply houses, and it is so closely allied to the hardware of building construction that the subject of glass, its trade terms, and other information relating to its characteristics, will not be out of order in this Section.

While little consideration is given to the hardware on the average building, there is no more important part of the construction, nor one to which greater attention should be given. On the quality and the selection of proper hardware depends the avoidance of the petty [Pg 2] annoyances often found in buildings where this subject has not received proper consideration.

The architect should be well informed regarding this subject, and should be in a position to know the kind and quality of hardware that, when specified, will give the best results. He will find that a thorough knowledge of builders’ hardware will assist him materially in writing comprehensive specifications for this portion of the work. Consequently, the writing of the hardware specifications will receive attention in this Section, and the proper manner of estimating, or “taking off,” hardware will also be considered.

2. Cut Nails.—The primitive nail was made or forged by hand, and this mode of manufacture still exists in certain sections of Europe. These hand-made nails sold at exorbitant prices compared with the machine-made nails of today.

The manufacture of cut nails is less automatic and requires more manual labor than is necessary in the making of wire nails. The iron or steel is first rolled into sheets, the thickness of which is equal to the thickness of the nail; it is then cut into strips as wide as the nail is long. This strip of metal is fed into the nail machine and sheared off in tapering strips having the form of the nail, when it is seized by clamps that hold it just long enough for the heading hammer to strike the blow that forms the head.

The nail manufactured in this manner is known as the cut nail, and is much superior to the wire nail, which is of more recent production. Not only has the cut nail greater holding power, but it is more durable, especially when used in damp places.

3. Nearly all cut nails used at the present time are made from sheet steel, a small percentage only being manufactured of iron, for which the makers charge a slightly higher price. The steel nail is [Pg 3] undoubtedly the best for use in hardwoods, but the iron nail will outlast it where dampness exists, as, for instance, in shingling, etc.

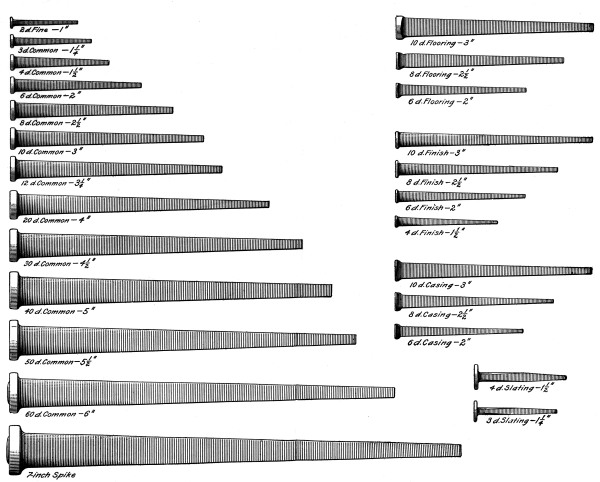

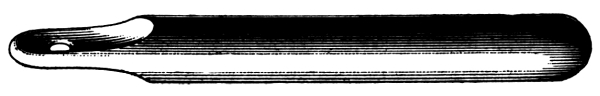

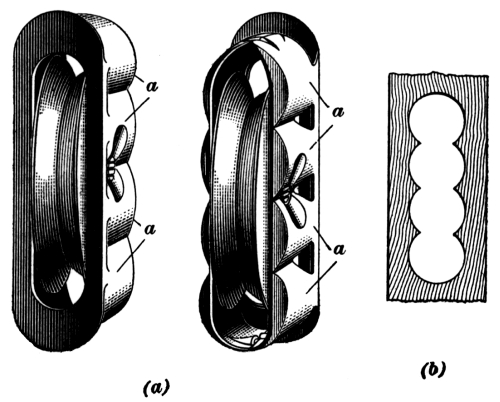

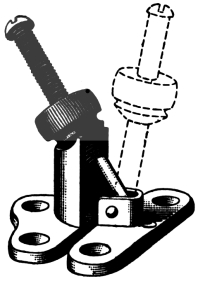

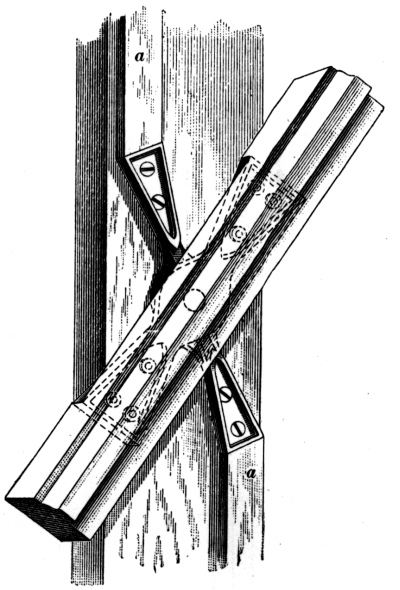

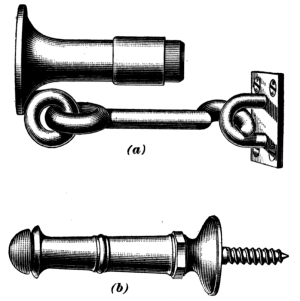

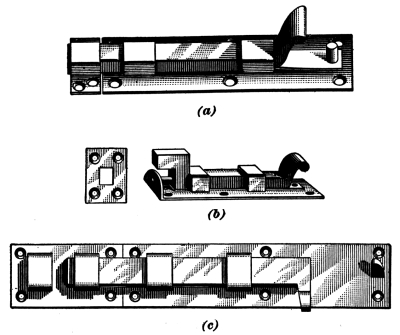

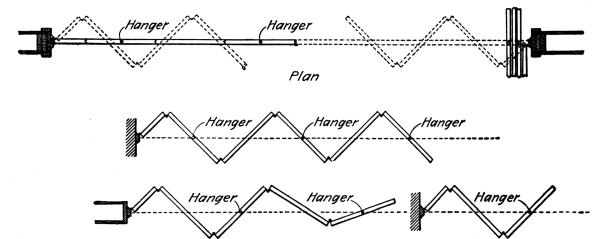

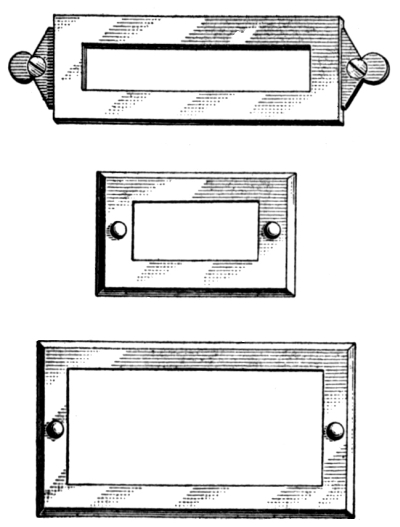

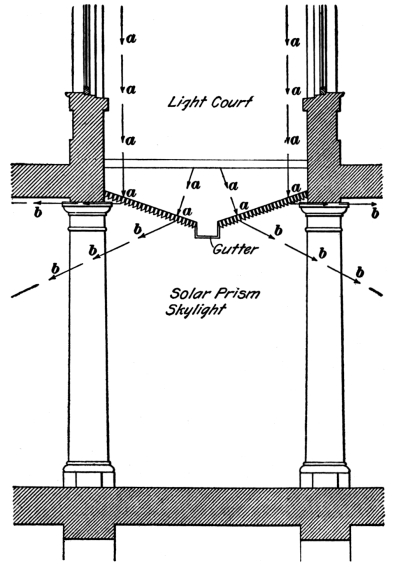

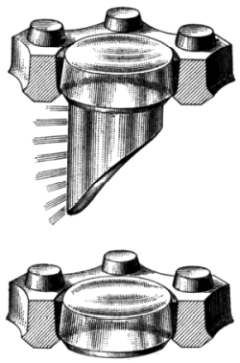

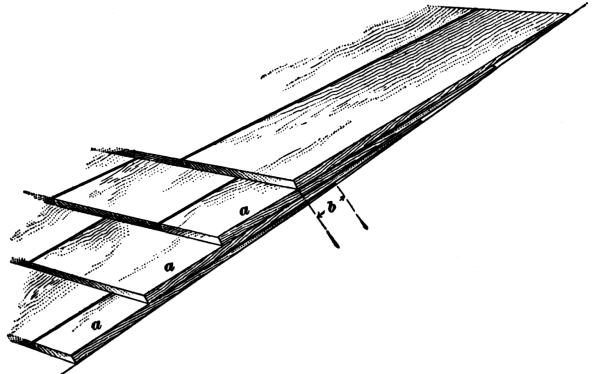

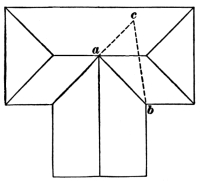

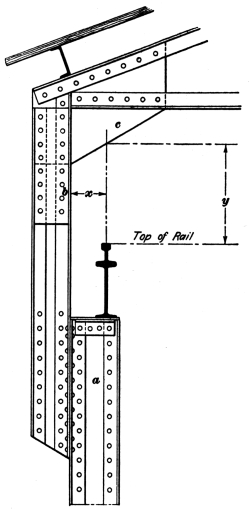

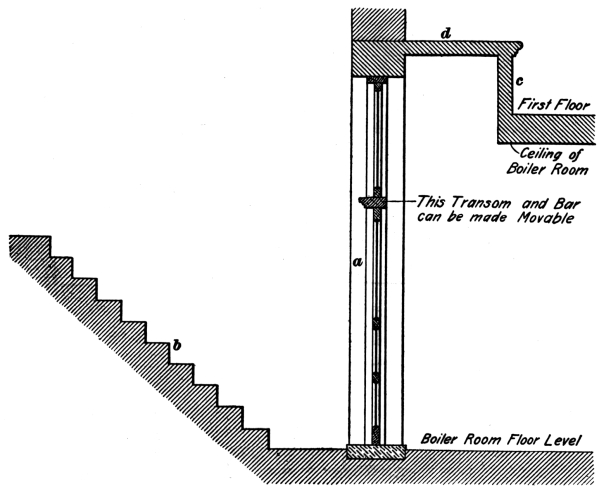

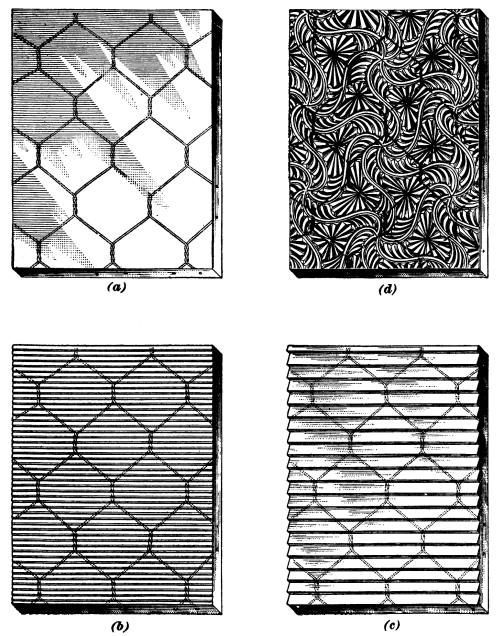

As shown in Fig. 1, cut nails are made in many styles and sizes, and for various purposes. They are also known by the same trade term for the various styles. Cut nails are heavier than wire nails, and as they count fewer to the pound, are more expensive at equivalent prices. All nails are sold at base prices per keg of 100 pounds, the “extras” for smaller and special nails being added to the base price. For special work, certain types of nails can be obtained in copper and brass.

4. Size and Gauge of Nails.—Both cut and wire nails are designated by the trade term penny. The term penny as applied to nails is a relic of medieval England. This designation was due, it is said, to the fact that it defined the cost per hundred nails, so that tenpenny nails would mean that 100 of such nails cost ten pence. A more likely interpretation of the term is that it implied the weight and not the cost, and that the term penny is a corruption of the Old English word pun’ (for pound), so that tenpunny or tenpenny implied that 1,000 of such nails weighed 10 pounds. The smallest standard size of nail is known as twopenny or threepenny, while the largest is designated as sixtypenny. These sizes range in length from 1 to 6 inches. In designating the size of the nail in list prices, the symbol “d” (for penny) is used, so that a nail about 2 inches long is designated as 6d. The thickness, or diameter, is indicated by the gauge number, the gauge of cut nails being an indication of the thickness of plate from which they are cut, while the gauge of wire nails is the size of the wire from which the nails are formed. The different wire gauges and their decimal equivalents of an inch are given in Table I. The special wire gauge commonly used to indicate the size of the nail is the Birmingham. In Table II is given a list of the stock sizes of standard, common, cut nails. This table, besides giving the thickness of the nail and its length, gives the number of nails to the pound. [Pg 4]

TABLE I

STANDARD WIRE GAUGES AND THEIR

DECIMAL EQUIVALENTS OF AN INCH

TABLE II

SIZE AND NUMBER TO THE POUND

OF COMMON CUT NAILS

| Trade Term | Length Inches |

Gauge | Number to Pound |

|---|---|---|---|

| 3d fine | 1⅛ | 16 | 720 |

| 3d flat | 1¼ | 15 full | 430 |

| 4d flat | 1½ | 14 full | 275 |

| 5d flat | 1¾ | 13 regular | 215 |

| 6d common | 2 | 12 regular | 150 |

| 7d common | 2¼ | 11 light | 120 |

| 8d common | 2½ | 11 regular | 96 |

| 9d common | 2¾ | 10 light | 72 |

| 10d common | 3 | 10 regular | 64 |

| 12d common | 3¼ | 9 regular | 44 |

| 16d common | 3½ | 8 regular | 32 |

| 20d common | 4 | 7 regular | 28 |

| 30d common | 4½ | 6 regular | 18 |

| 40d common | 5 | 5 regular | 14 |

| 50d common | 5½ | 4 regular | 12 |

| 60d common | 6 | 3 regular | 10 |

Fig. 1

5. Wire Nails.—The term wire nail is applied to nails made from drawn wire, or wire rods. Since their introduction some years ago, wire nails have become decidedly popular, and in some localities are used in preference to the old-style cut nails, owing to the fact that there are a greater number to the pound, which makes them cheaper than cut nails at the same price per keg. The size and number of common wire nails to the pound are given in Table III. By comparing the columns in Tables II and III giving the number of nails to the pound for both cut and wire nails, it can be readily seen that the wire nails are greater in number for a given weight than cut nails of the same size. For this reason, the wire nails are used by contractors on cheap work. [Pg 7]

Wire nails are more liable to rust than cut or wrought nails, and are consequently not so durable in damp situations; they also have less holding power and more must be used to obtain the same strength.

TABLE III

SIZE AND NUMBER TO THE POUND

OF COMMON WIRE NAILS

| Size |

Length Inches |

Gauge Number |

Approximate Number to the Pound |

Advance Over Base Price per 100 Pounds |

|---|---|---|---|---|

| 2d | 1 | 15 | 876 | $0.70 |

| 3d | 1¼ | 14 | 568 | .45 |

| 4d | 1½ | 12½ | 316 | .30 |

| 5d | 1¾ | 12½ | 271 | .30 |

| 6d | 2 | 11½ | 181 | .20 |

| 7d | 2¼ | 11½ | 161 | .20 |

| 8d | 2½ | 10¼ | 106 | .10 |

| 9d | 2¾ | 10¼ | 96 | .10 |

| 10d | 3 | 9 | 69 | .05 |

| 12d | 3¼ | 9 | 63 | .05 |

| 16d | 3½ | 8 | 49 | .05 |

| 20d | 4 | 6 | 31 | Base |

| 30d | 4½ | 5 | 24 | Base |

| 40d | 5 | 4 | 18 | Base |

| 50d | 5½ | 3 | 14 | Base |

| 60d | 6 | 2 | 11 | Base |

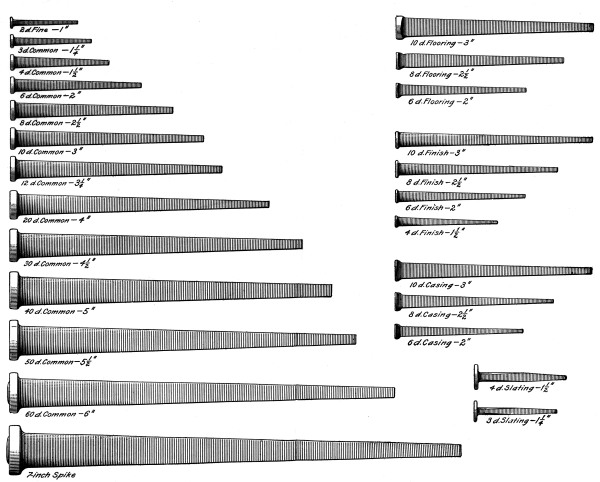

Fig. 2

[Pg 8] Common wire nails in sizes from twentypenny to sixtypenny are sold at base price, say $2 per keg, the smaller sizes costing an advance over the base price. Thus, an eightpenny common nail would cost 10 cents additional, or $2.10 per hundred pounds, while a twopenny nail would cost $2.70 per hundred pounds, etc. The present advance above the base price on 100-pound kegs for the several sizes is also given in this table. All wire nails can be procured “barbed” at an additional advance of 15 cents above base and extra prices.

The relative sizes of the common wire nail are best learned from samples of the same, but Fig. 2, which shows these nails full size, from sixtypenny to twopenny, clearly indicates their proportions.

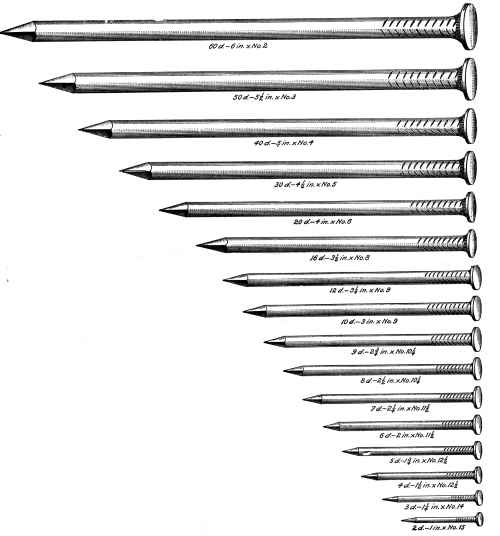

Fig. 3

6. Wire Nails for Special Purposes.—Wire nails as well as wrought or cut nails are made in a variety of forms especially suitable for the specific purpose for which they are intended. The several kinds of wire nails in common use are illustrated in Fig. 3.

A nail used about buildings for putting the trim, or finishing work, together is illustrated at (a), and from its use is known as a finishing nail. These nails are used almost exclusively for this [Pg 9] purpose and are very light. They have a small head, so that when they are set into the wood with a nail set, a very small opening is left for puttying.

Another nail having practically the same use as the one just described is designated as a casing nail, and is shown at (b). This nail is a trifle lighter in gauge than the finishing nail, and from the fact that it is countersunk under the head, it draws better than the finishing nail. The fivepenny and sixpenny sizes are used for putting on siding.

The common wire brad, shown at (c), is used for practically the same purposes as the regular finishing nail, but it is from two to four gauges heavier. This wire brad is useful when a heavy nail with a small head is required, particularly in hardwood, where a light finishing nail will not penetrate without bending.

The flooring brad, shown at (d), is a nail used almost exclusively for flooring. This nail is made of heavier gauge wire than other nails of this type, and drives easily, even in hard, maple floor. The construction of the head of this type of nail allows for severe “drawing” without splitting the tongue of the flooring boards.

The fine-wire nail, shown at (e), commonly called a lath nail, is made in four sizes and is used for nailing lath to studding. Owing to its smoothness, cleanliness, and easy-driving qualities, this type of nail is extensively used.

A short, heavy nail, the whole length of which is barbed to increase its holding qualities, is shown at (f). This nail is known as a barbed roofing nail, and is generally used for nailing tin roofs and ready, or prepared, roofing of every description. It is also used with tin roofing caps.

At (g) is shown a slating nail. This type of nail is formed from heavy gauge wire, and has a flat head that is large in proportion to its length. This nail is used only for slating, but is not so durable as the cut nail made for this purpose. Nails of this kind are made in only five sizes.

A type of nail used for attaching wooden shingles, and known as the shingle nail, is shown at (h). This nail is seldom carried in stock, however, as threepenny and fourpenny common nails [Pg 10] answer the purpose. These shingle nails are clean and easily driven, but are not so durable as cut nails.

A very heavy nail of the same character as the common wire nail, but made much heavier, in order to increase the holding qualities and to provide greater durability, is known as the fence nail. This nail is made as shown at (i).

At (j) is shown a clinch nail that is manufactured from soft wire or annealed hard wire. This nail answers the same purpose as the old-style wrought, or clinch-cut, nail commonly used in the construction of batten doors, etc. The metal being very soft at the end of the nail, allows the point to be bent and driven back into the wood to form the clinch. These nails do not differ from the common wire nail, except in the form of the head and the material from which they are made, as will be seen from Fig. 3 (j) and Fig. 2.

There is a form of headless wire nail, known as a barbed dowel-pin, which is made as shown in Fig. 3 (k). This type of nail, or dowel, is used for doweling through the mortises and tenons of sash, blinds, and frames of every description. In the mill, it has displaced the wooden dowel used in former times. The length of pin to be employed is regulated by the thickness of the wood to be secured, as the pins are used ¼ inch shorter than the thickness of the woodwork.

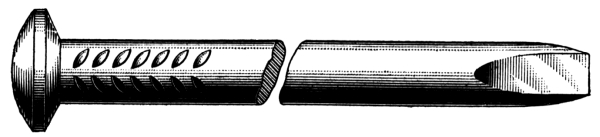

Fig. 4

An exceptionally heavy nail, or spike, is made from heavy wire or round bar. These spikes are used for heavy construction work, such as splined flooring, for slow-burning mill construction, and for bridge flooring. They are made with both chisel points, as shown in Fig. 4, and diamond points, and in ordering them, the kind of point, as well as the style of head wanted should be specified. Spikes of this kind are made in all [Pg 11] sizes from tenpenny, which is of No. 6 gauge and 3 inches long, to spikes ⅜ inch in diameter and 12 inches long.

7. Galvanized Nails and Spikes.—Nails and spikes, either cut or wire, that have been dipped into molten zinc and become coated with this metal are termed galvanized. By this process they are rendered practically rust-proof. Cut or wire galvanized nails can be obtained in the same sizes and types as ordinary nails, and if dealers do not regularly carry them in stock, they will as a rule have them galvanized to order. In order to secure durability, it is advisable to use galvanized nails in places that are exposed to dampness, as in shingling, in slating, in fence building, or in structures erected near the seashore, as it has been proved by numerous tests that ordinary nails rust through in such places in a few years. The galvanized nails cost from $1.50 to $3 more per keg than the plain cut or wire nails.

The cheaper grades of galvanized nails are frequently coated only with lead, and will not withstand the government test; that is, dipping them into vitriol. A simple way to test the coating of a galvanized nail is to rub the nail on a piece of white paper. A lead-coated nail will mark the paper the same as a lead pencil and should be rejected, as it is only a sham and has no redeeming qualities.

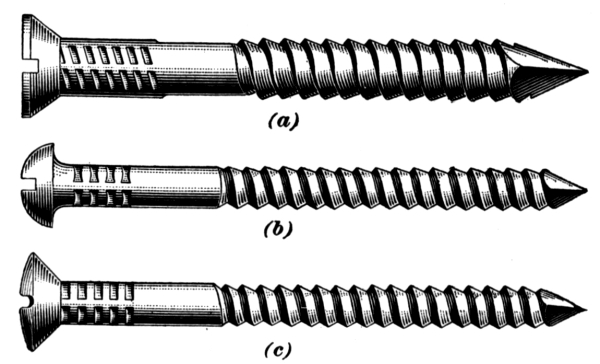

8. Wood Screws.—The ordinary wood screw, which is one of the staple articles of hardware, is very necessary in the application of all builders’ hardware about the building. Except in some lines of cheap or rough, unfinished goods, hardware manufacturers now pack with all hardware, screws that match the finish of the goods. The various types of screws now on the market are illustrated in Fig. 5, and the common types, such as flat-, round-, oval-, and fillister-headed screws are easily procured.

Iron screws are made with either flat, round, or oval heads and the [Pg 12] following finishes: Bright, blued, japanned, tinned, galvanized, bronze-plated, brass-plated, coppered, silvered, and nickel-plated. Brass and bronze metal screws can also be procured with flat, round, or oval heads, in either natural color or, on special order, finished to match the hardware. Special screws are also manufactured for various purposes, which are sufficiently explained by the illustration, Fig. 5.

Fig. 5

Screws are always measured for length from the point to the top of the head. The sizes in which screws can be obtained are given in Table IV. The diameter of screws is always measured directly under the head, and is always given in numbers of the screw makers’ gauge. The numbers vary [Pg 13] from 0 to 30, going consecutively without skip from 0 to 18 and from then on using only the even numbers. In Table IV are also given the numbers of the screw makers’ gauge and their equivalents in decimals of an inch.

TABLE IV

SIZE OF WOOD SCREWS

| Length Inches |

Diameter in Screw Makers’ Gauge |

|

|---|---|---|

| ¼ | From | 0 to 4 inclusive |

| ⅜ | From | 0 to 9 inclusive |

| ½ | From | 1 to 12 inclusive |

| ⅝ | From | 1 to 14 inclusive |

| ¾ | From | 2 to 16 inclusive |

| ⅞ | From | 2 to 16 inclusive |

| 1 | From | 3 to 20 inclusive |

| 1¼ | From | 3 to 24 inclusive |

| 1½ | From | 3 to 24 inclusive |

| 1¾ | From | 5 to 24 inclusive |

| 2 | From | 5 to 24 inclusive |

| 2¼ | From | 5 to 24 inclusive |

| 2½ | From | 5 to 24 inclusive |

| 2¾ | From | 6 to 24 inclusive |

| 3 | From | 6 to 26 inclusive |

| 3½ | From | 8 to 26 inclusive |

| 4 | From | 8 to 30 inclusive |

| 4½ | From | 12 to 30 inclusive |

| 5 | From | 12 to 30 inclusive |

| 6 | From | 12 to 30 inclusive |

Screw Makers’ Gauge

| Number of Screw Gauge |

Equivalent in Decimals of an Inch |

|---|---|

| 0 | .05784 |

| 1 | .07100 |

| 2 | .08416 |

| 3 | .09732 |

| 4 | .11048 |

| 5 | .12364 |

| 6 | .13680 |

| 7 | .14996 |

| 8 | .16312 |

| 9 | .17628 |

| 10 | .18944 |

| 11 | .20260 |

| 12 | .21576 |

| 13 | .22892 |

| 14 | .24208 |

| 15 | .25524 |

| 16 | .26840 |

| 17 | .28156 |

| 18 | .29472 |

| 20 | .32104 |

| 22 | .34736 |

| 24 | .37368 |

| 26 | .40000 |

| 28 | .42632 |

| 30 | .45264 |

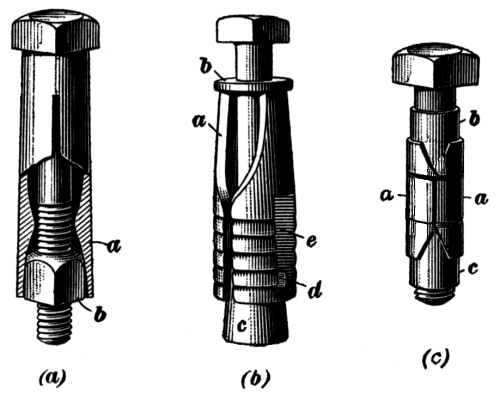

9. Drive Screws.—A screw known as the drive screw is used mostly in the manufacture of various articles where cost is the [Pg 14] controlling factor. These screws, shown in Fig. 6, are made somewhat on the order of the wood screw, but without the deep-cut thread and gimlet point. Screws of this type are driven into the wood with a hammer and have slotted heads so that they may be withdrawn by means of a screwdriver. The thread is so constructed that the wood may be penetrated without breaking down its fiber when the screws are driven, and is shaped so as to engage with the wood while resisting a pulling stress. These screws are made with flat, round, or oval heads, as illustrated respectively at (a), (b), and (c), and may be had in sizes from ½ inch to 4 inches in length.

Fig. 6

10. Expansion Bolts.—The expansion bolt is a device that has proved extremely valuable in the building trades, as it provides a means of bolting to stone, brick, concrete, slate, or other materials of this nature. Expansion bolts are used principally in places where it is not desirable or practicable to drill through the material to which the fastenings are to be made. This type of bolt has also a great advantage over other fastenings in that it can be removed with as much ease and facility as it is applied, and also without injury either to the article fastened or the material to which it is fixed, the bolt likewise sustaining no injury.

Many styles of expansion bolts are now manufactured under various patents, and these may be procured in all sizes and made of iron, steel, or brass. [Pg 15]

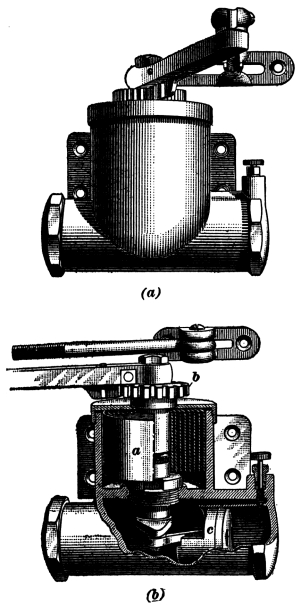

In Fig. 7 are shown several makes of expansion bolts. The McCabe expansion bolt, shown at (a), is constructed of a malleable, cylindrical-shaped, slotted case, or shell, a, the aperture of which reduces in size and engages with a bevel-shaped hexagon nut b. By turning the bolt, the nut is drawn toward the head and thus expands the outer case in its passage; this in turn binds against the sides of the hole in the masonry into which the bolt is inserted. The shell, as the outside case a is called, can be procured in any length or diameter, and can be used with any machine bolt having a standard thread. The McCabe bolt is suitable for bolting any thickness of material, provided the proper length of bolt is employed.

The Brohard expansion bolt shown at (b), performs the same functions as the bolt illustrated at (a). The case, or shell, a, is composed of two or more parts riveted to a wrought circular plate, near the head, as at b. These several parts are expanded by means of the beveled nut, which approaches the head as the bolt is turned. The principal feature of the Brohard expansion bolt is that the beveled nut c cannot be forced from the case on account of the lug d, which is attached to the nut and travels in the slot e when the bolt is turned.

Fig. 7

The Steward and Romaine double-expansion bolt is shown at (c). The shell of this bolt is composed of two semicylindrical parts, as at a, a, that are somewhat longer in diameter than the wedge-shaped nut and the sleeve at b and c, respectively. Each half of the shell is held in place by light rubber bands. The wedge-shaped parts are caused to approach each other by the turning of the bolt, and thereby expand the split case at both ends [Pg 16] simultaneously. From the fact that this bolt is expanded at both ends, it is called a double-expansion bolt, although it may be made single-expansion by omitting the wedge-shaped sleeve at the head.

Fig. 8

The Star expansion bolt, shown in Fig. 8 (a), performs exactly the same duty as other expansion bolts, but its construction is radically different. This bolt consists of only two parts, called shields. Each shield is semicircular in form and interlocks at the joints. The exterior of these shields has four rows of corrugated ridges, or star-shaped projections, that prevent the shields from turning in the hole. The interior of the shell is threaded and decreases in size toward the farther end. Thus, by inserting a lag, or coach, screw of any length, so as to engage with the thread, the shields are spread apart at the farther end while the screw is entering the aperture.

The Diamond expansion bolt shown at (b) is practically the same as the one just described, as will be observed from the figure.

Expansion bolts are also made with all the parts entirely of brass or bronze, with either plain, capped, or fancy heads, or nuts, and in any finish desired.

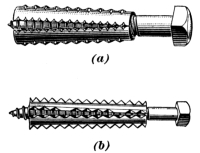

11. Screw Anchors.—The device known as a screw anchor can be used in place of an expansion bolt for securing light materials. Several kinds of screw anchors are in the market at present. The star anchor, which is made in one piece of composition metal that is slotted about seven-eighths of its length, may be obtained in various diameters and lengths. The exterior has two star-like projections, to prevent the anchor from turning, while the interior is constructed of ridges projecting from the tube, with the hole reduced toward the slotted end. This internal construction permits the star anchor to be used in combination with trade wood or machine screws of [Pg 17] any length. The screw used engages with the ridges in the interior, cutting its own thread and expanding the anchor in its passage. These composition anchors are very cheap, the price ranging from 1 to 3 cents, according to the size. They are made in different lengths, from ½ inch to 1½ inches, and for Nos. 6, 10, 14, and 18 wood screws.

Fig. 9

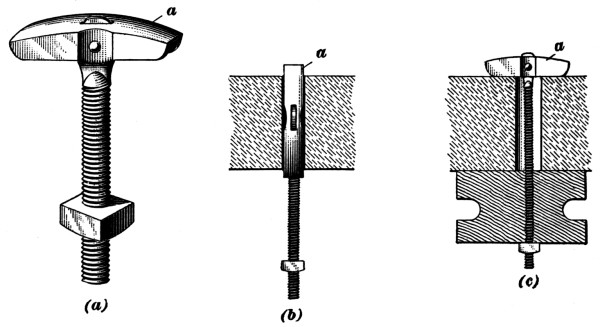

12. Special Bolts.—In Fig. 9 is shown a toggle bolt. This device is a recent production for fastening materials to surfaces having a hollow interior that will not admit the use of expansion or tap bolts because of its frail character, as, for instance, sheet metal, hollow fireproofing, etc. The toggle bolt shown in the figure is constructed with long, fine-pitch threads cut nearly to the head, so as to allow for securing thin materials. The T-shaped head a is constructed either hollow, as shown in the figure, or of flat strip metal, and is riveted loosely to the end of the bolt, allowing the head to pivot and fold over the bolt, and thus permitting the head to pass through a small opening. The head is then tipped into its proper position, when the bolt is ready for securing in place the work to be fastened. The construction of the bolt is shown in Fig. 9 (a), while the process of affixing it is illustrated at (b) and (c). These toggle bolts are generally made with ³/₁₆-, ¼-, and ⁵/₁₆-inch bolts, from 2½ to 6 inches long, and of either iron, steel, or brass. [Pg 18]

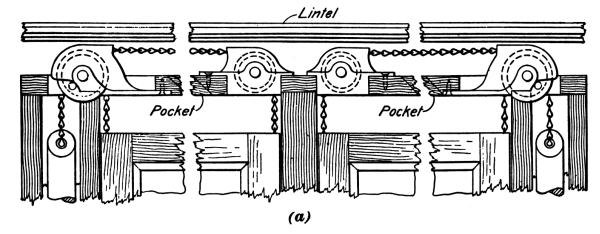

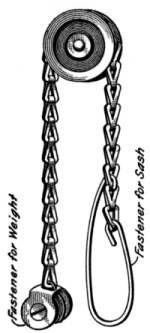

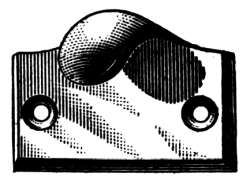

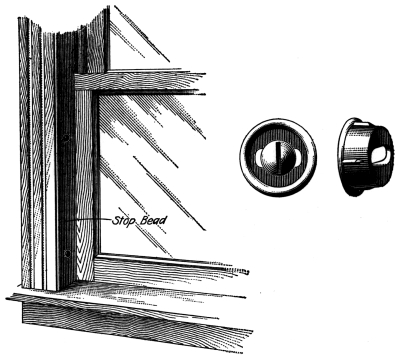

13. Cast-Iron Weights.—The term sash weight is applied to a counterweight used for balancing double-hung, or sliding, sash. These weights are generally very rough, being made from either the poorest iron or waste iron. The stock sizes are usually long and cylindrical in form—from 1⅜ to 2¼ inches in diameter—have an eye cast in the upper end, as shown in Fig. 10, and weigh from 2 to 30 pounds, the weight determining the length of the sash weight. In Table V are given the weight, diameter, and length of sash weights as they are generally furnished to the trade, although it is almost impossible to give this data with any degree of accuracy, as the different manufacturers vary the diameters of the weights slightly, and this changes the length measurement. Square weights or special weights can be easily procured at small additional cost.

Fig. 10

Fig. 11

14. Lead Weights.—The weight of lead is about 80 per cent. greater than that of cast-iron; hence, lead sash weights must be resorted to where the construction of the pockets is too narrow to permit the use of iron weights, or where heavy plate glass is used. They are also used in cases where the sash are very wide and low, as here a short weight must be used in order to obtain the necessary travel for the sash.

Lead weights can be procured in either round or square shapes, and of any diameter or measurement to suit existing conditions, but they are generally made to special order. A wrought- or malleable-iron eye, or fastening, for applying the cord or chain is usually inserted at the [Pg 19] top. The cost of lead weights, however, is generally five times as great as that of iron weights.

15. Sectional Sash Weights.—There is a form of sash weight in the market known as the Walda sectional weight, which is illustrated in Fig. 11. This weight, as will be observed, is so arranged that units or sections may be detached or added, as desired, to diminish or to increase the weight. Such a weight can be nicely adjusted to counterbalance any sash, and has the advantage over the cast-iron weight in that each part is interchangeable and no mistake can be made in ordering, as the necessary weight for any sash can be made up on the site.

TABLE V

WEIGHT, DIAMETER, AND LENGTH

OF SASH WEIGHTS

| Weight Pounds |

Diameter Inches |

Length Inches |

Weight Pounds |

Diameter Inches |

Length Inches |

|---|---|---|---|---|---|

| 3 | 1⅜ | 8½ | 12 | 1¾ | 20 |

| 3½ | 1⅜ | 9¾ | 13 | 1¾ | 21½ |

| 4 | 1⅜ | 11 | 14 | 2 | 18 |

| 4½ | 1⅜ | 12¼ | 15 | 2 | 19 |

| 5 | 1½ | 12 | 16 | 2 | 20¼ |

| 5½ | 1½ | 12½ | 17 | 2 | 21½ |

| 6 | 1½ | 14 | 18 | 2 | 22½ |

| 6½ | 1½ | 15 | 19 | 2 | 23½ |

| 7 | 1½ | 16 | 20 | 2 | 24½ |

| 7½ | 1½ | 17 | 21 | 2⅛ | 25 |

| 8 | 1½ | 18 | 22 | 2¼ | 23 |

| 8½ | 1⅝ | 16½ | 23 | 2¼ | 24 |

| 9 | 1⅝ | 17½ | 24 | 2¼ | 25 |

| 9½ | 1⅝ | 18½ | 25 | 2¼ | 25½ |

| 10 | 1⅝ | 19½ | 26 | 2¼ | 26 |

| 10½ | 1⅝ | 20½ | 27 | 2¼ | 27 |

| 11 | 1⅝ | 21½ | 28 | 2¼ | 28 |

| 11½ | 1¾ | 19 | 29 | 2¼ | 28½ |

16. Historical.—From the days of Tubal-Cain, “an instructor of every artificer in brass and iron,” to the present time, no element in the world’s composition has rendered greater service in advancing man’s development than has the uninviting metal known as iron.

Recent discoveries show the very ancient existence of iron in Assyria, and also in Egypt under the Pharaohs. It was found in considerable quantities in Syria, in Canaanite times, and many tools and implements of warfare were made from it. The Chalybes, located near the Black Sea, were in Biblical times considered famous workers in “northern iron,” while Damascus steel, for ages, has been justly celebrated.

Copper was well known to the Israelites and Egyptians before the Exodus, and for many years previous to that event the Egyptians obtained it from Arabia. It was also a native product of Palestine, and was very largely exported from Cyprus, whence its name.

Tin was early known in the Orient, being one of the imports of Egypt from Spain, through the Phoenician merchants, who also obtained it from Britain. It was one of the principal commodities in the marts of Tyre, and was used as an alloy with other metals.

Gold and silver, the precious metals, are mentioned in the earliest times and were highly esteemed; they were utilized in the manufacture of articles for domestic use, for personal adornment, and for ceremonial accessories. These metals were obtained by the Hebrews from Arabia, Ethiopia, Egypt, and Spain. Gold was used as a medium of exchange, like money, as early as the time of Abraham, but was then [Pg 21] weighed, not counted. Silver was profusely used at that time in the East, and seems to have been very abundant in the time of Solomon. An alloy of gold and silver, called electrum, was also used.

Zinc was discovered in 1520 by Paracelsus, an alchemist and astrologer of Europe, and was immediately adopted as a valuable alloy.

Bronze, a composition of copper and tin, seems to have been much used in Europe before the adoption of iron for the same purposes, as Roman remains testify; this was probably due to its greater ease in working.

Brass, a composition of copper and zinc, soon became popular, owing to its being more easily worked than bronze.

Burnished brass is mentioned in Ezekiel, but is considered to have been an alloy of copper, there being a white metal, greatly used for ornaments in the East, called white copper.

Locks and contrivances to secure protection and privacy were originally made of wood, and a wooden lock (the oldest yet discovered) was actually found in the ruins of Nineveh. This lock appears to have been used on a gate of an apartment in one of the palaces of Khorsabad. The ancient Egyptians constructed locks and keys from brass and iron, thus showing their creative mechanical skill, while the ornaments discovered in the royal tombs display the high order of their art.

The Greeks and Romans were skilled workers in the metals, and many beautiful examples remain to attest their ability and ingenuity.

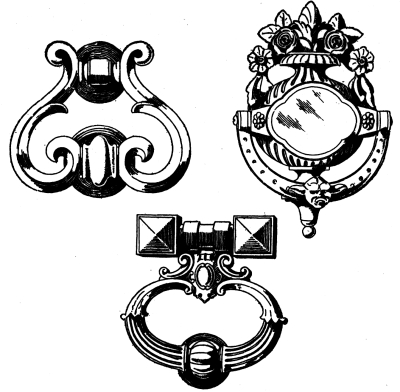

During the dark ages, following the conflict waged between the barbarians of Northern Europe and the Romans, and resulting in the fall of the Roman Empire in the 5th century, the art of working the metals nearly disappeared. Not until the Revival of Learning in the 13th century did the art again receive the attention to which it was entitled. As late as the reign of Edward III, of England, in the 14th century, the iron pots and pans of the royal kitchen were listed among the “jewels of His Majesty.” During the 15th and 16th centuries, great [Pg 22] progress was made among all civilized nations by skilled artificers. Much of their work is still extant, and their “cunning of hand” and “keenness of intellect,” as displayed in their products, serve, like torches, to light the way to higher endeavor. From that time to the present, great progress has been made. During the latter half of the 17th, the 18th, and the beginning of the 19th centuries, especially, art work received a great impetus, and much of the present-day adaptations are modeled from the schools of ornament then produced.

17. Metals Used in Hardware Manufacture.—The metals chiefly used in manufacturing the products of the smiths’ art are iron and steel and the copper alloys known as brass and bronze. Iron remains as the chief material of construction for all the cheaper grades of hardware, while brass and bronze are more generally used for “destructible,” or wearing, parts and the finer and more elaborate decorative work. These alloys also adapt themselves admirably to the great variety of finishes that are now in vogue. Iron is also used considerably for elaborate decorations in wrought and cast designs, and is very desirable in the “rustless-iron” finish, technically known as “Bower-Barff,” which derives its name from its two inventors.

White metal has been recently introduced, but will probably not be so universally adopted as brass or bronze, owing to the great number and variety of items used in hardware fittings, which would necessitate stores carrying a full line of white-metal goods. At present, white metal is used principally for hospital buildings and bathrooms.

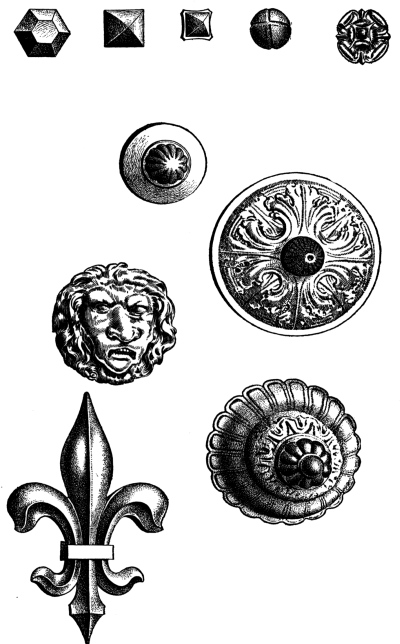

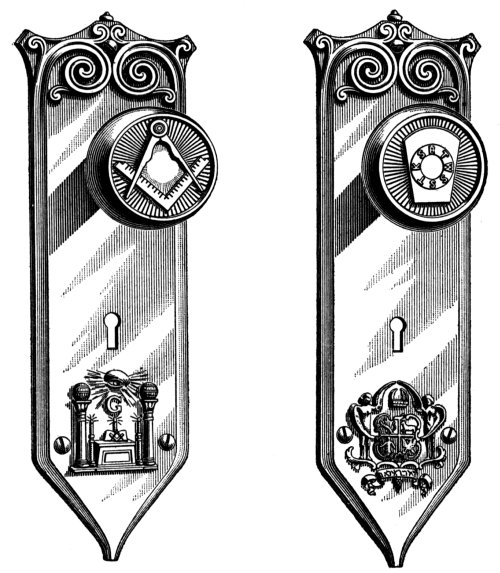

18. Commercial and Stock Designs.—In recent years, manufacturers have made rapid strides in producing beautiful and elaborate trim in the several schools of ornament, and the most exacting critic can now procure artistic designs. The finishes are made to harmonize or contrast with any color treatment.

The principal hardware manufacturers can provide from stock, locks, hinges, and escutcheons finished in any manner and designed in any of [Pg 23] the following schools of architectural ornament. They will also provide hardware in special designs from sketches furnished by the architect, including armorial or emblematic designs, if required. These several schools of ornament are here arranged in alphabetical order.

| Byzantine | Gothic, French |

| Colonial | Gothic, German |

| Elizabethan | Gothic, Italian |

| Empire | Greek |

| English Renaissance | Henry II |

| Flemish | Indian |

| Francis I | Italian Renaissance |

| French Renaissance | Japanese |

| German Renaissance | L’Art Nouveau |

| Gothic, English |

19. Finishes.—The basic metals upon which are applied the variety of finishes now obtainable, are iron, steel, brass, bronze, and white metal, of which the three latter, even in their highly polished natural state, are the most durable. These metals will not rust or corrode when exposed as will iron or steel, and when tarnished can be readily cleaned and polished.

Nearly all the fancy finishes are obtained by electroplating and acid treatment on the natural metals, the finish being then lacquered to preserve it. Some of these finishes are very attractive and desirable, but where exposed to constant usage, have not the durability of the natural metals, as they cannot be polished or cleaned without the finish being injured or destroyed.

Many architects or owners purposely select applied finishes with the object in view that they will need little attention. When selections are being made for exterior purposes or where there is likely to be excessive handling, it is best to select the darker shades with sanded surfaces. For interior purposes, the more delicate finishes are desirable for the decorative effect; they also wear reasonably well.

The variety of colors and shades of finishes is exceedingly large, and [Pg 24] the choice of color, like that of texture, depends on the character of the design and on the personal taste of the one making the selection.

The standard finishes that can be had are numerous. Many of them may be obtained in various shades of oxidation and in from one to four different textures of surface. The most popular finishes are as follows:

| Pompeian bronze | Copper |

| Sage-green bronze | Nickel |

| Royal copper bronze | Silver |

| Ormolu metal | Gold |

| Boston finish | Bower-Barff |

| Enameled | White enamel |

| Japanned | Gun-metal brown |

| White metal | Verde antique |

| Brass | Statuary bronze |

| Bronze | Olive bronze |

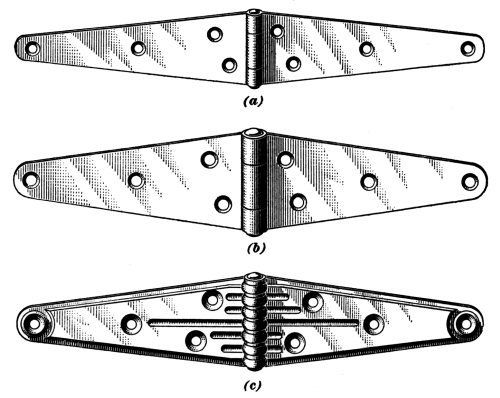

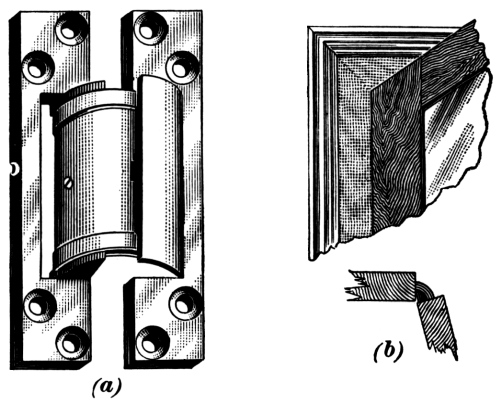

20. Strap Hinges.—The common wrought hinges used to apply on the surface, for hanging doors, etc., and generally used in connection with rough work, such as bins, sheds, barns, etc., where a strong, serviceable hinge that may be easily applied is required, are known as strap hinges. They are constructed of wrought metal of various weights, according to the size of the hinge, and are stamped or cut from sheet metal, with knuckles, or sockets for the pins, formed on the strap; the pins passing through the knuckles are well riveted. There are two kinds of strap hinges; namely, light-strap and heavy-strap hinges.

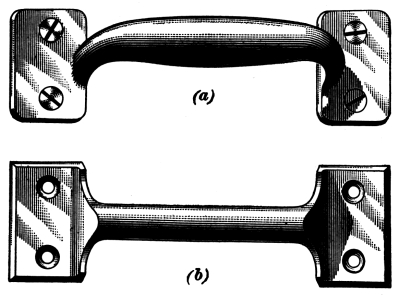

The light-strap hinge, which is shown in Fig. 12 (a), is so termed because of its light construction and narrow joint. This hinge is made in inch sizes, varying from 3 to 16 inches in length. By inch size is meant the longest dimension when the hinge is closed; thus, a 6-inch strap hinge is 12 inches long from end to end when opened. They are listed and sold by the pair. [Pg 25]

Fig. 12

The heavy-strap hinge, which is shown at (b), is similar to the light hinge, but is made from heavier metal and has large dimensions at the joints, or knuckles. This type of hinge is used where a strong, substantial hinge is required. The heavy-strap hinge is made in inch sizes, from 4 to 16 inches in length. The 4- and 5-inch sizes are listed and sold by the pair, the 6-inch and larger sizes being listed and sold by the pound; the larger the hinge the lower the price per pound.

As shown at (c), the heavy-strap hinges are also made with corrugated knuckles, which give additional strength where the construction is weakest. These are termed corrugated-strap hinges.

All of the hinges described are also made in plain steel, japanned or galvanized, and may have brass pins or rivets.

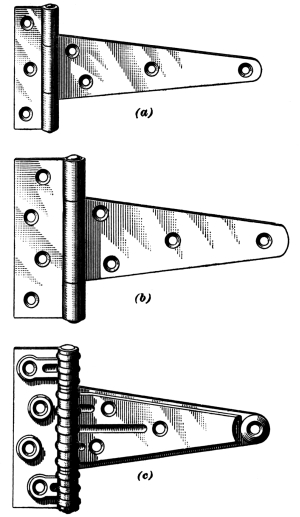

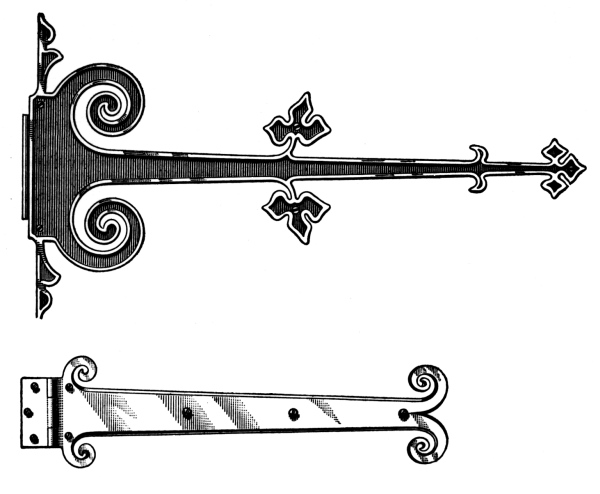

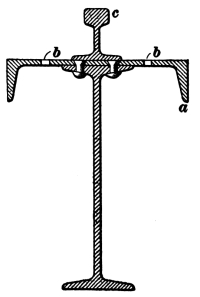

21. T Hinges.—As will be seen from Fig. 13, T hinges are so called to distinguish them from the strap hinge, as well as because of their construction, which is in the form of the letter T. The [Pg 26] T hinge is used for practically the same purpose as the strap hinge, but is superior to it in strength, from the fact that its knuckle is wider than that of the strap hinge. T hinges are made in light, heavy, and extra-heavy grades, the former and latter types being shown in Fig. 13 (a) and (b). In arranging the sizes of T hinges, the measurements are given for the length of the strap only; the leaf of the hinge forming the T with the strap is not considered. Thus, a 6-inch T hinge measures 6 inches from the pin to the end of the strap leaf. T hinges may also be obtained in stamped metal, with corrugations, as shown at (c). These hinges can be had in all finishes. The light and heavy grades, as well as the 4- and 5-inch extra-heavy grades, are sold by the pair, while the larger sizes of extra heavy are sold by weight.

Fig. 13

22. Hinge Butts.—In the selection of hardware for building purposes, no other article deserves more consideration, and probably receives less, than the hinge butt. This type of hinge is used for the purpose of hanging all of the exterior and interior doors of buildings, and is usually secured to the edge of the door and to the [Pg 27] hanging stile of the frame with screws, the greater part of the appliance being thus unobtrusive and partly hidden from view. The hinge butt supports the entire weight of the door, and, ordinarily, is constantly in use, so that it is subjected to excessive strain and considerable wear. It is evident, therefore, that great care should be exercised in selecting hinge butts, so that proper sizes and qualities suitable for the purpose intended may be obtained.

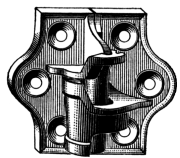

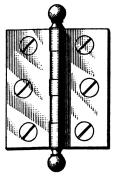

Fig. 14

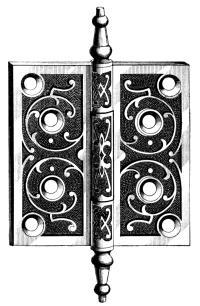

23. Cast-Iron Hinge Butts.—Hinge butts made of cast-iron are used extensively in the cheaper class of buildings built for speculative purposes, in which cost is usually the controlling factor. An ornamental type of the cast-iron hinge butt is shown in Fig. 14. Butts of this type are not extensively used at present, but may be obtained in various finishes to imitate bronze or brass, and may likewise be obtained without ornamentation. As the genuine Bower-Barff finishes are produced with equal facility on iron or steel, a large number of the better grade of cast butts are finished in this manner.

While the cast-iron hinge butt is not so durable as the steel butt, being more easily broken when subjected to excessive stresses, it wears somewhat better at the joints, or knuckles, than the ordinary steel butt. Therefore, the extra-heavy types of cast-iron are becoming more [Pg 28] popular for entrance doors, etc., where a good wearing butt is required, and where economy is the essential feature. The heavier grades of cast-iron butts can be procured with steel bushings inserted into the joints.

Fig. 15

Fig. 16

Fig. 17

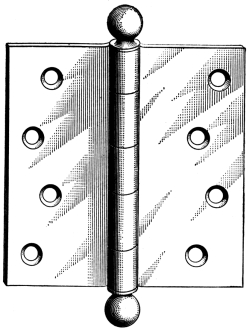

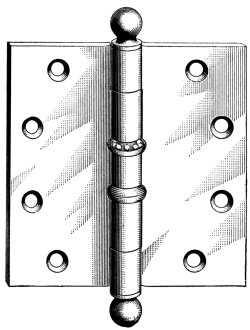

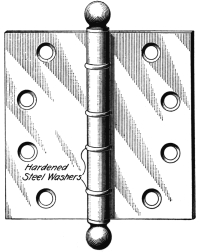

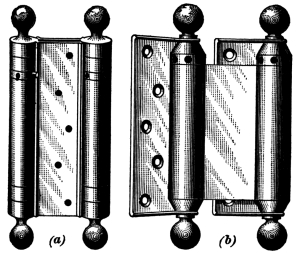

24. Steel Hinge Butts.—In recent years, the steel hinge butt, which is shown in Fig. 15, has been substituted for the cheaper cast-iron butts. The better grades are made with ball tips, as indicated in the figure, and these are now almost universally used for medium-class work and for the better class of interior work. Owing to the fact that they are made up with smooth surfaces, the steel hinge butts are adapted to the various buildings and finishings without grinding or buffing. These butts are stamped and formed by machinery, so that their cost is reduced to a minimum; they can be sold for less than cast-iron butts, and also possess the advantage over the latter in [Pg 29] that they are practically unbreakable. The ordinary grades are not suitable for large and heavy entrance doors that are constantly in use, for they are made of soft steel and wear readily at the joints. Thus, in time, they will allow the door to sag and thereby necessitate readjustment, or the planing of the door at the sill. For such class of work, steel hinge butts should be used that are provided with ball bearings, as shown in Fig. 16, or with hardened-steel washers inserted at the joints, as shown in Fig. 17.

These steel butts are also made in smaller sizes, and for bookcases, cupboard doors, and light work of this kind in ordinary building operations, they are used almost exclusively, having practically forced the small cast butts for this class of work out of the market.

Fig. 18

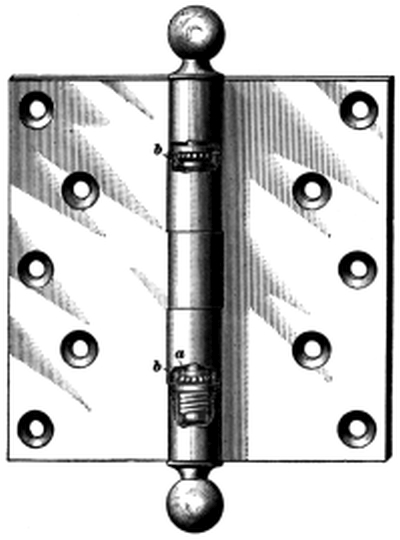

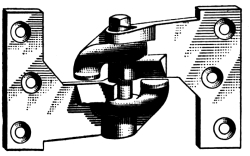

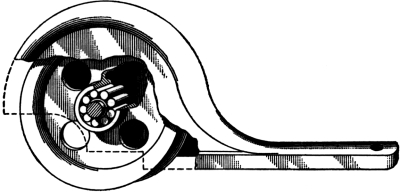

25. Cast-Bronze and Brass Butts.—All types of brass and bronze butts are made in several grades and qualities, and it is difficult to determine the grade after they have been placed in position. It is therefore advisable for the architect or building superintendent to make a careful inspection of this hardware, to determine whether it is furnished according to specification. Brass and bronze butts are made in light, or commercial, heavy, and extra-heavy grades, and in all cases should be steel-bushed, self-lubricating, and provided with five knuckles. The high-grade butts are now manufactured with ball bearings at the wearing joints. The construction of a solid bronze, ball-bearing hinge butt is shown in Fig. 18. In this figure, the [Pg 30] hardened-steel balls are shown at a, and the cones, which are also of hardened steel, at b. Bronze hinges constructed in this manner can be obtained at a slight additional cost above the ordinary steel-bushed hinge.

Where hinge butts are exposed to the weather, as when used for exterior doors, bronze or brass butts should always be employed; and for extra-heavy doors that are in constant use, only the extra-heavy types should be used if permanency and durability are desired. There are a number of cheap grades of bronze, steel-bushed hinges on the market that are made of wrought or sheet metal. This kind of hinge has no merit, and should not be used on work of any quality.

26. Sizes of Hinge Butts.—The standard hinge butts are always square, but they may be procured in irregular sizes, at additional cost. In indicating the size of irregular hinge butts—that is, the butts that are not square, and that are consequently not standard—two dimensions must always be given. The first dimension stated should indicate the height of the butt, and the second the width of the butt when it is open. Thus, a 6" × 5" butt is 6 inches high and 5 inches wide when opened. This rule for indicating the size of hinge butts is [Pg 31] easy to remember, from the fact that it is the reverse of that ordinarily employed by builders when indicating the sizes of doors and windows, for here it is customary to give the horizontal dimension first and the height of the opening last.

Fig. 19

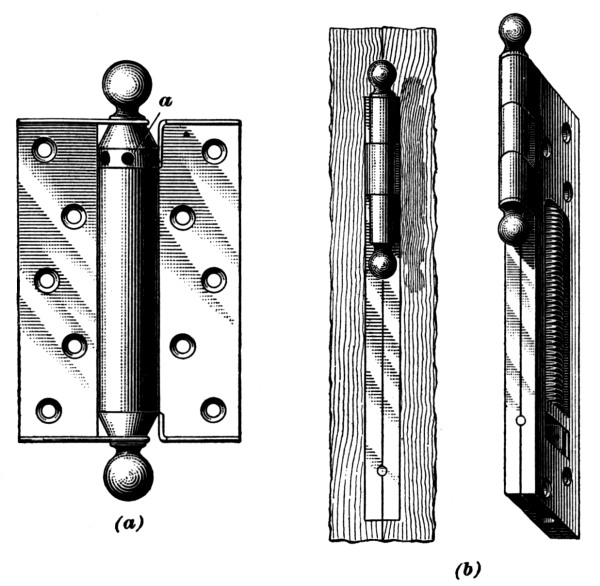

27. Single-Acting Hinges, or Butts.—There is a large butt, or hinge, in the market that has a coil spring either between the knuckles, or enclosed between the leaves. This device is known as the single-acting hinge, and is illustrated in Fig. 19. At (a) is shown the Bommer single-acting hinge, which has a spiral spring enclosed within the casing formed by one of the knuckles. The tension on this spring can be increased by operating the collar at a with a pin, or bar. At (b) is shown a single-acting spring hinge known as the Chicago single-acting spring butt. This hinge butt has a spiral spring that is encased between two leaves. In operating, this spring always tends to throw the door back to its closed position. These two kinds of single-acting hinges are used more [Pg 32] than any other hinge of the same nature now in the market, but for doors of large size the liquid door check is preferred, although it is more costly. Single-acting hinge butts are used principally for hanging water-closet slat doors; and they are also used for light doors that do not reach the full height of the opening, and which have no jambs. The Bommer hinge, as shown in Fig. 19 (a), has an advantage on account of the simple means provided for adjusting the tension of the coil, or spring, by which the momentum of the door in swinging to and fro can be reduced to a minimum, thus shutting the door with little noise as it strikes the stop.

Fig. 20

Two other types of the Bommer single-acting spring hinge are shown in [Pg 33] Fig. 20. At (a) are shown two types of single-acting, surface, spring hinges that are used for lavatory doors, while at (b) is shown a similar single-acting spring hinge arranged for securing to a marble or slate stile or partition. These hinges are commonly supplied in highly polished nickel plate, brass, or bronze. The clamp hinge illustrated at (b) is made to secure to slabs of marble or slate from 1 to 2 inches in thickness, advancing by quarter inches. This type of hinge is also adjustable ⅛ inch over and under the stated sizes.

Fig. 21

The Bommer yoke-spring hinge is also made as illustrated in Fig. 21. This yoke hinge consists of two single-acting hinges hung right and left of the same partition on one box flange, the yoke or box flange being constructed as shown at a. As the box flange of this spring is not adjustable, the exact thickness of the marble, or partition, and the door must always be stated in ordering these hinges.

The single-acting spring hinges with clamps, as just described, are fastened to the marble partitions separating water-closet compartments by means of bolts having capnuts, as shown at b, Fig. 21, and are thus secured firmly in position. Special single-acting hinges may be obtained with a reverse spring that can be regulated to hold the door partly open, instead of in a closed position.

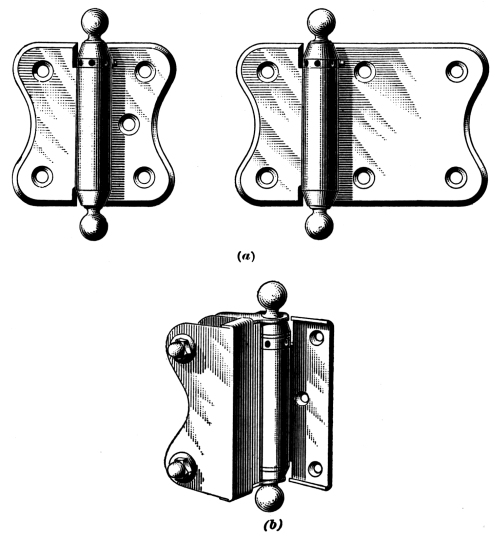

28. Double-Acting Hinges.—The double-acting hinge is similar in construction to a single-acting hinge, except that it is [Pg 34] arranged so that the door can swing both ways. These hinges are combined in one piece of hardware, as illustrated in Fig. 22. Such hinges are much heavier and more costly than the single-acting hinge, and they are generally used for entrance doors of hotels and public buildings, and for doors between kitchen and pantry or dining room in private residences, where a door that will swing both ways and return to a closed position is desirable. The double-acting hinge is usually subjected to excessive wear and strain. Care should therefore be exercised in selecting this type of hinge; also, in determining the size, it is better to have a hinge slightly larger than required rather than one that is too small. While double-acting spring hinges made of cast-iron may be obtained, those of the latest manufacture are of steel. They may also be procured in brass or bronze, and of any desired finish to match the fixtures and other hardware.

Fig. 22

Fig. 23

[Pg 35] In Fig. 23 is shown another type of double-acting spring hinge that is not so compact as those illustrated in Fig. 22. This hinge, as shown, is operated by a coil spring that fits into a rabbet formed in the two leaves of the spring; thus, the coil is invisible when the door is closed, or in its normal position. This hinge obtains a good purchase on the door and jamb.

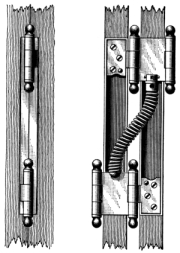

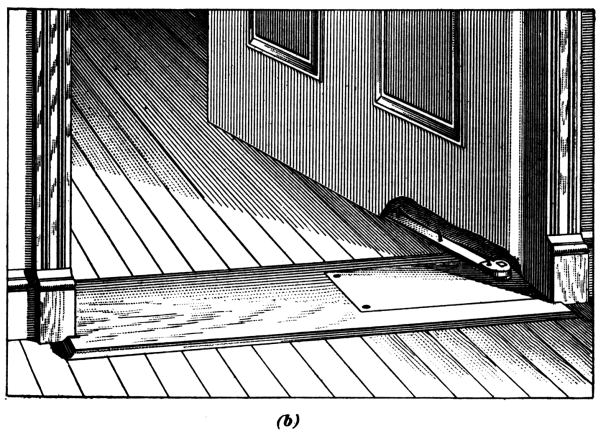

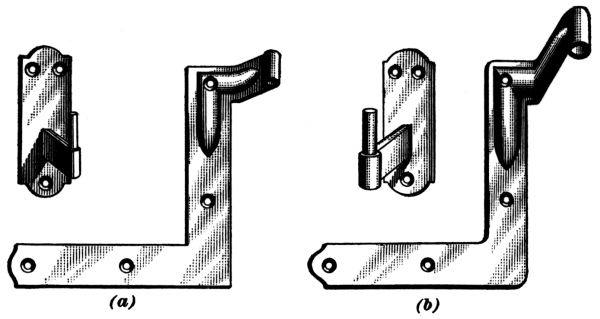

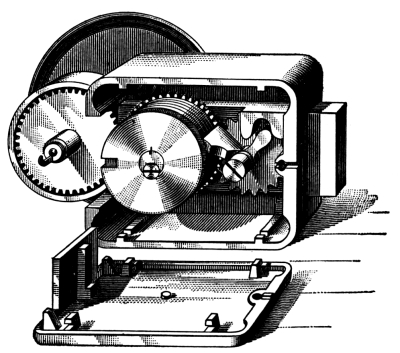

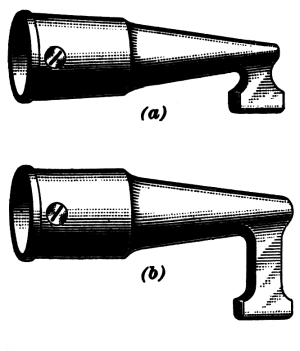

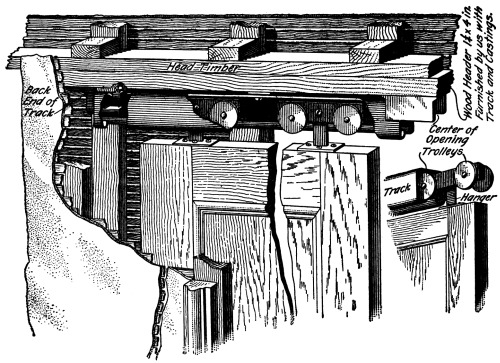

29. Floor Hinges.—A device is made for hanging single- and double-acting doors by means of pivots, or trunnions, placed at the top or the bottom. The top pivot is usually inactive; that is, it has no spring or other device, and is simply a trunnion, or pivot, with the necessary plate to engage it fastened to the edge of the door trim. The bottom piece of hardware, on the other hand, is arranged with a pivot and a coil spring, and has various mechanisms for operating the door positively and silently.

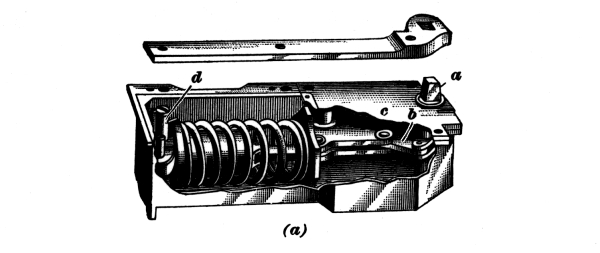

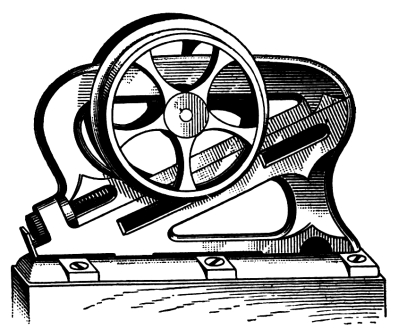

In Fig. 24 is illustrated a single-acting, checking-spring hinge. This spring hinge is known as the Bardsley, and its mechanism, which is enclosed in a cast-iron box, is shown at (a). This box, or case, is set into the floor, the top plate being made flush with the top of the floor, as shown at (b). The operating bar, or pivot, of the hinge has a square end, as shown at a, that engages with the plate secured to the bottom edge of the door, and is connected to the mechanism by means of a crank and connecting link, as at b. After being set into the floor, the cast-iron box, or case, containing the spring, piston cylinder, etc. is filled with oil or other non-freezing liquid, and sealed by means of the top plate c. The action of the door in opening compresses the spring and operates the piston in the cylinder. The spring operating to close the door also moves the piston and forces the oil in the cylinder out through a by-pass, the flow being regulated by the adjusting screws d, which are on a level with the top plate. In this manner, the door is closed surely but gently, from which the hinge derives its name of checking-spring hinge. Hinges of this type can be used without any modification of the door or frame, but are not extensively used on account of their high price and the cost of application. [Pg 36]

Fig. 24

[Pg 37] For pivoting the door at the top, there is provided a top pivot and plate, as illustrated at (c). This pivot is applied to the edge of the door stile. Both the top pivot and bottom hinge plates on the door are offset.

Fig. 25

Double-acting floor hinges are rapidly displacing double-acting spring hinges. This is due to the fact that when the former hinges are employed the door is pivoted at the top and bottom and the weight of the door is not carried by the coils of the spring, as in the double-acting spring hinge. The floor type of double-acting hinge carries the weight of the door on a ball bearing in the box, or case, let into the floor, as shown at a, Fig. 25, the coil performing only the function of closing the door. The hinge illustrated is not only a double-acting hinge, but is also a checking hinge, and for this reason is known as a double-acting, checking-spring hinge. In operating, this spring hinge not only closes the door, but prevents it, when closing, from oscillating after the door has reached its neutral, or closed, position. [Pg 38]

There are numerous double-acting floor hinges in the market that are not of the checking type. Some of these are the Atlas and Simplex, made by Bardsley, the Bommer, made by Bommer Brothers, together with the Chicago, New Idea, Matchless, Chief, and Columbia, made by various manufacturers. All of these hinges embody practically the same principle, but differ somewhat in mechanism.

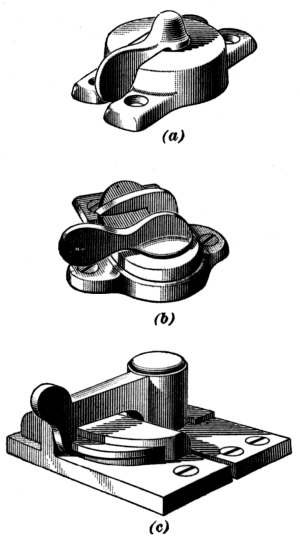

30. Outside Blind and Shutter Hinges.—The outside shutter, or blind, is still much used in the construction of dwelling houses, and a great variety of hardware is made to use in conjunction with hanging these devices. Only the most common of the many available types of this kind of hardware, however, will be treated here.

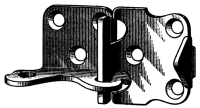

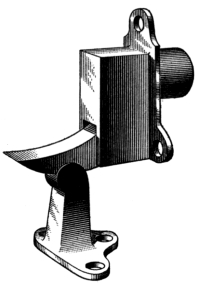

The hinge illustrated in Fig. 26 may be classed among the oldest types of shutter hinge. This hinge is made of cast-iron and is formed with a gravity-locking device intended to hold the shutter in position when opened against the building. It is known as the Lull and Porter hinge, and is made in various sizes that are designed to throw the shutter from 1½ to 6½ inches away from the casing, so as to clear all obstructions consequent to the various constructions. A sill catch must be used in conjunction with this hinge, in order to hold the shutter in place when closed and to prevent it from blowing open.

Fig. 26

Fig. 27

A similar type of hinge, known as the Clark hinge, is illustrated in Fig. 27. This hinge is made of cast-iron, and in three sizes, which are arranged to throw the blind 1¼, 3¼, or 4¼ inches from the casing. The hinge with the largest throw is used on brick [Pg 39] buildings. With this hinge, as with the one just described, a sill catch must be used to keep the shutter closed.

Fig. 28

In specifying cast-iron hinges of the types just considered, it is well to mention that they shall be extra heavy, from the fact that there are so many in the market of such light construction as to be practically worthless.

A type of the gravity-locking hinge, which is better than the cast-iron hinge, is illustrated in Fig. 28. This hinge is made entirely of steel, and is known as the Stanley gravity blind hinge. There is only one size of this hinge manufactured, and it is used for frame buildings. All of the parts of this hinge are interchangeable and reversible, so that it may be used for either right- or left-hand blinds.

There is a wrought-steel hinge, known as the Stanley blind hinge, which has not the gravity-locking device, but which obtains a greater purchase on the shutter. This hinge is illustrated in Fig. 29; the hinge shown at (a) is for frame buildings, while that shown at (b) is arranged for brick walls.

Fig. 29

Another type of hinge made entirely of wrought steel, and known as the New York blind hinge, is shown in Fig. 30. This type of hinge has a long strap that extends on the top and the bottom rail of the [Pg 40] shutter and thus tends to prevent the blind from drooping. This strap also strengthens the shutter by relieving the mortise and tenon of the rail and stile from the strain. The New York blind hinges are made in two styles. The hinge shown at (a) is intended for frame buildings, while that at (b) is made with an offset to throw the shutter clear of a brick jamb. These hinges are ordinarily used with blind adjusters, or fasteners, and for very high blinds, a center, or auxiliary, hinge is used.

Fig. 30

Fig. 31

There is another type of strap hinge similar to those just described, the butt of which consists of a pin and staple, as shown in Fig. 31. This staple is secured by driving it into wooden blocking in the brick joints. Hinges of this type are used extensively in localities where brick buildings are numerous.

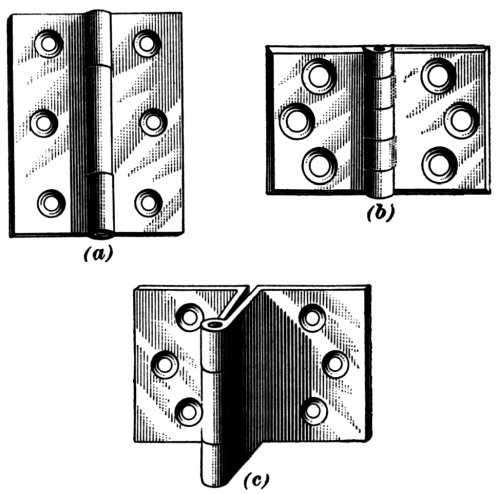

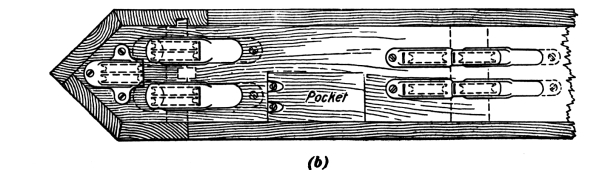

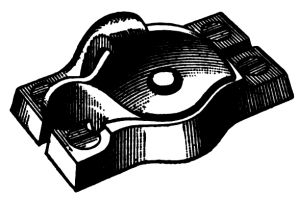

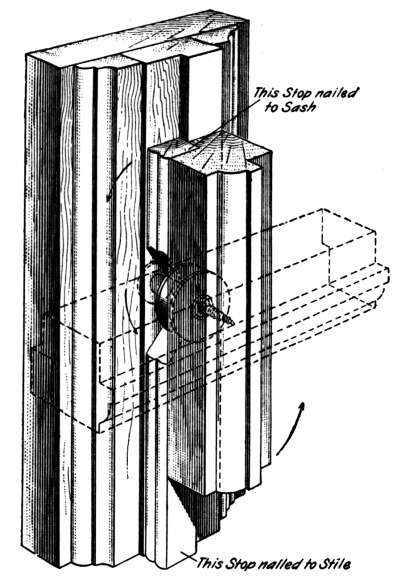

31. Inside Blind, or Shutter, Hinges.—The use of inside blinds, [Pg 41] or shutters, is general with the better class of domestic buildings, and for hanging these shutters, three kinds of hinges are used, depending on the number of folds in the shutter and the manner in which they fold back on each other. Usually, the butt and the back flap, as shown in Fig. 32 (a) and (b), are used. Where the shutter has three folds, however, a knuckle butt, as shown at (c), is employed. The purpose of the knuckle butt is to cause the folds to take such relative positions as will enable them, when open, to close properly into a pocket, or recess, formed in the window frame.

Fig. 32.

Fig. 33

Fig. 34

Fig. 35

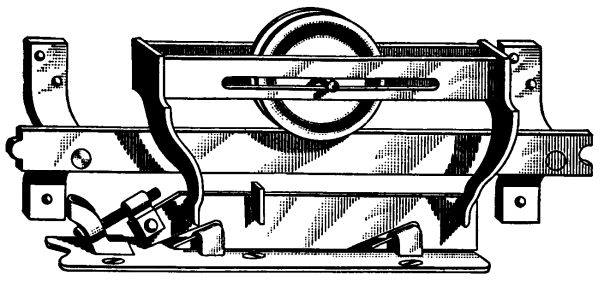

32. Invisible Butts, or Hinges.—A secret, or invisible, hinge, known as the Soss hinge, has recently been placed on the market. This hinge, which is illustrated in Fig. 33 (a), consists of a semicircular plate, which is attached rigidly to the door section, and a movable semicircular plate on the jamb leaf, which telescopes the section on the door in closing. These hinges are invisible when the door is closed. The disadvantage in the use of these hinges is due to the fact that they have only one wearing joint; they are also somewhat complicated and expensive. As shown in Fig. 33 (b), they have no throw, or offset, and consequently the door [Pg 44] does not clear the baseboard, or trim, in opening. The larger size of hinge has a throw of 1 inch, which is not ordinarily sufficient for doors. These hinges, however, have their use for such mill work as seats, secret jambs, drop, or folding, leaves, etc., and for this class of work are the best in the market.

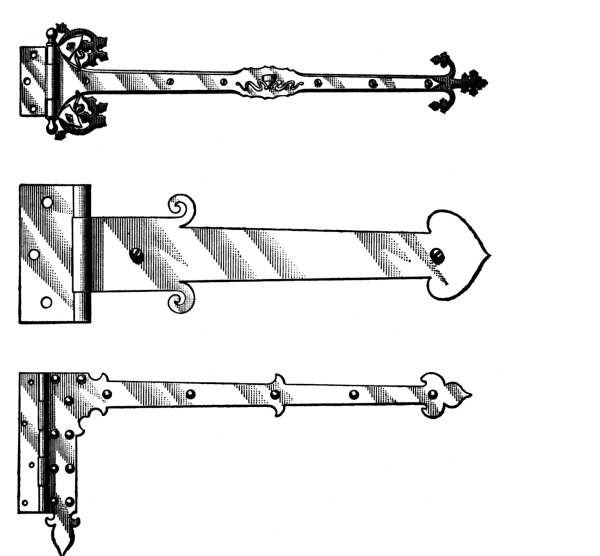

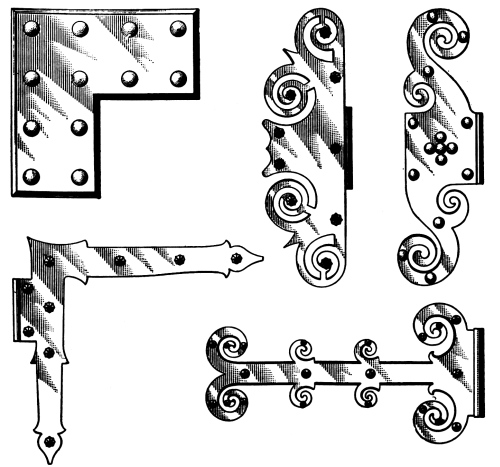

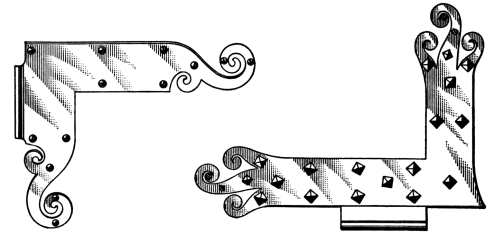

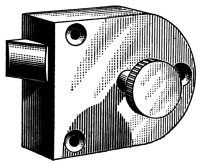

33. Strap and Corner Hinge Plates.—Medieval hardware was the product of the blacksmith and the whitesmith, the former working with forge and hammer, and the latter with chisel and file, the material being wrought iron. The butt hinge was unknown, while the strap, or surface, hinge was in universal use; and, as this was wholly in sight, it naturally became the subject of decoration, chiefly in outline, but occasionally in surface ornament also. With the adoption of the butt hinge for general use, the opportunity of utilizing the hinge to decorate the surface of the door disappeared, but with the modern revival of decorative art the use of constructive metal work as a feature of surface decoration for important doors was restored. This was accomplished by combining with the modern butt a surface plate that represents the strap hinge. Obviously, the width of the butt of a hinge plate should correspond with the height of the butt hinge with which it is to be used, and both should be of the same metal and finish. The other dimensions are governed by the size of the door and by taste, as is true also in the case of corner plates. A varied and artistic selection of typical strap hinges and corner plates is given in the groups of designs shown in Figs. 34 and 35.

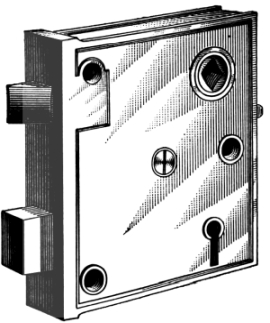

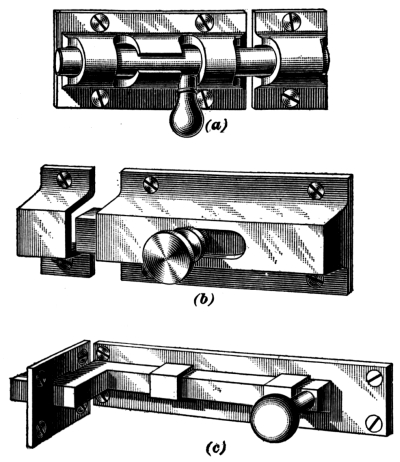

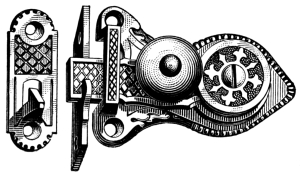

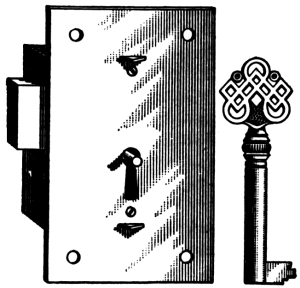

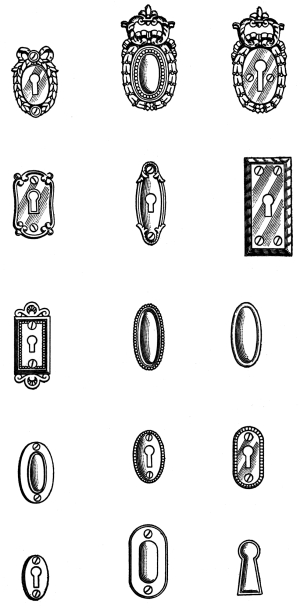

34. Locks in General.—In no other line of hardware is there such a variety of grades and types as there is in door locks. In general, locks may be designated as surface and mortise locks, the former being secured to the surface of the door and entirely exposed to view, while the latter are let into a mortise cut in the edge of the stile. Besides these two general kinds of locks, [Pg 45] there are several special locks, which will be fully explained. As to quality, locks may be classified in three grades; namely, common, medium, and high grade.

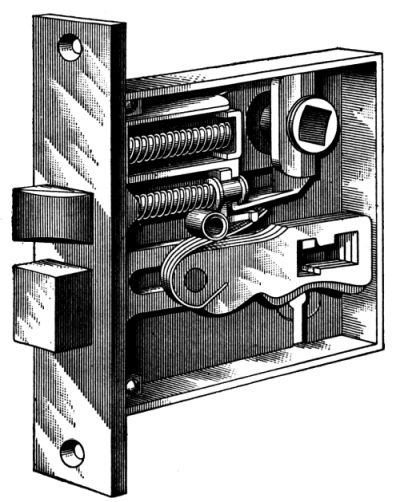

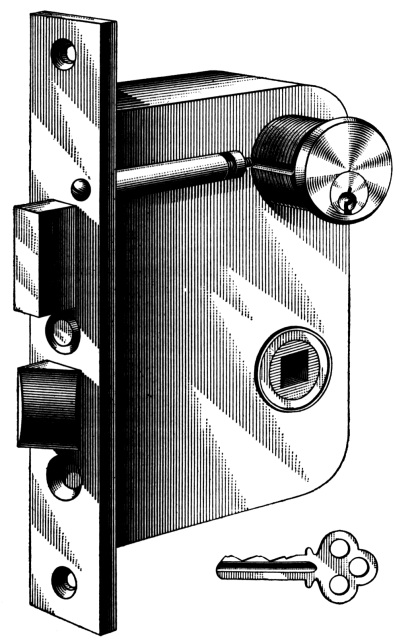

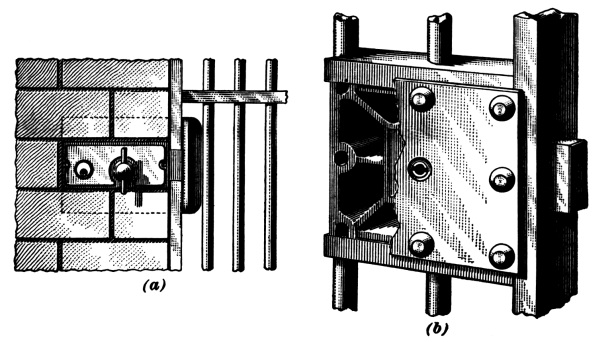

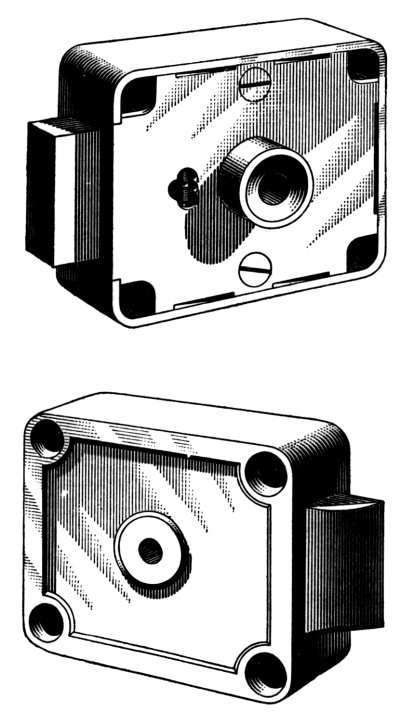

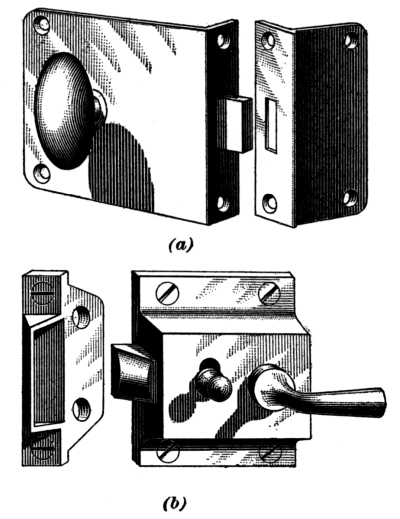

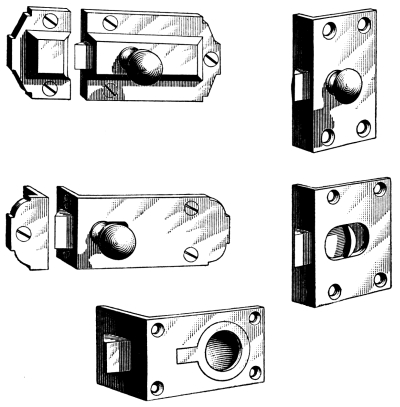

Fig. 36

Fig. 37

35. Common-Grade Rim and Mortise Locks. The rim lock, as illustrated in Fig. 36, is generally used for buildings of the cheapest class, such as tenements and small houses. As cheapness is the controlling factor in such goods, especially the goods made for speculative building purposes, the quality diminishes with the price. For cheap work, rim locks are used on account of their low cost and because they are easily applied. They also require no trim, such as escutcheon plates, etc., and are complete when the spindle and the knob are furnished with them. Rim locks are made in various sizes and either square or rectangular in shape, the long dimension being placed either horizontal or upright. They may also be obtained with either iron or brass bolts, and are furnished with iron, tinned, or nickel-plated keys. The cheapest grades of rim locks are made with two bolts and one [Pg 46] tumbler, while the better grades have an additional stop and a slide bolt with three tumblers.

Rim locks are generally constructed of cast-iron, and in selecting them, a careful inspection should be made of the internal mechanism, choosing only those rim locks in which the bolts and the tumblers are constructed of steel or brass. Rim locks, however, are also made of all steel, and these are coming into general use. They present a somewhat better appearance than cast-iron locks, as may be seen from Fig. 37.

The cast-iron rim lock may also be obtained with an ornamental case. These cast-iron cases, as a rule, are finished in imitation of bronze. Such rim locks, however, are not in general use on account of their somewhat higher cost, and from the fact that their appearance is not greatly improved by the ornamentation.

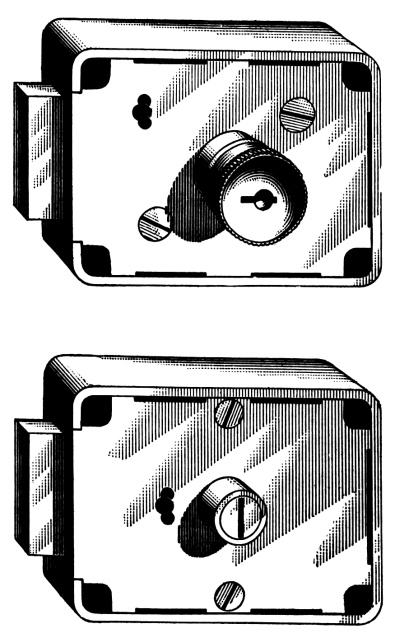

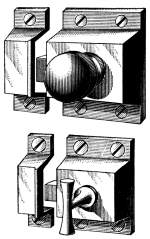

Fig. 38

Cheap mortise locks, or sets, are also largely used for the more common grades of work. They are sold in sets, that is, with escutcheon plates, etc. of steel or cast-iron, both in plain and [Pg 47] ornamental designs, as illustrated in Fig. 38. The cheapest lock sets are fitted with pottery knobs, and the better grade, with metal knobs. All of these locks described are of poor construction, as quality is a secondary consideration.

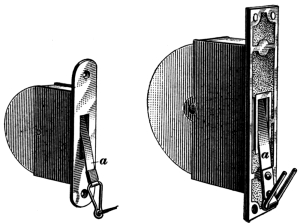

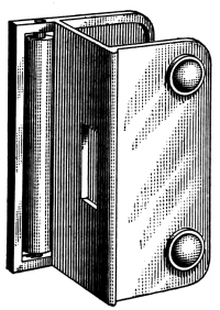

Fig. 39

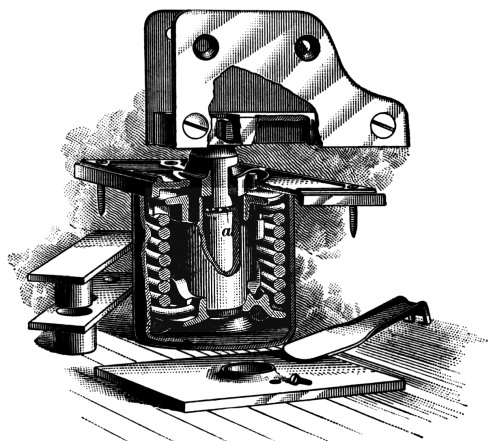

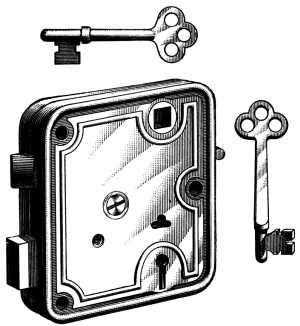

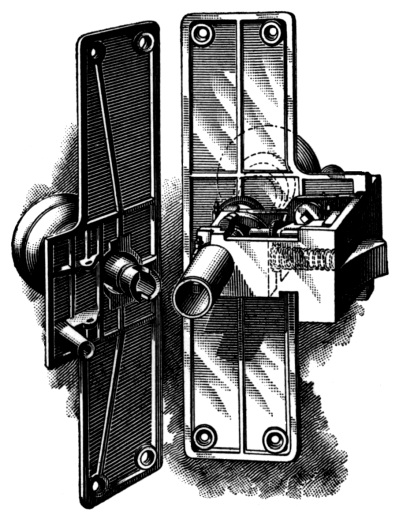

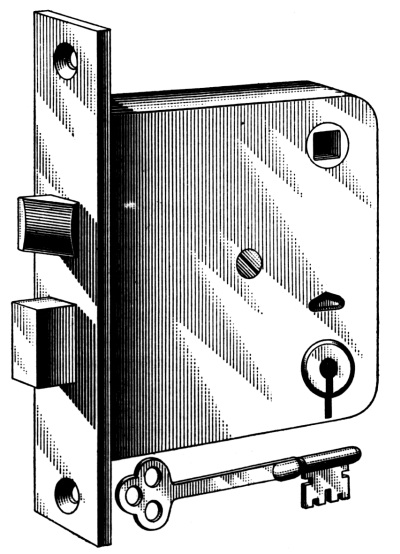

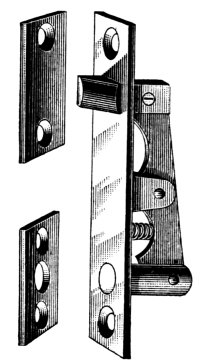

36. Medium-Grade Mortise Locks.—The locks grouped under the term “medium-grade” hardware have been greatly improved in recent years and are adapted to a large range of uses, but they are especially made for residence work. In dwellings of the better class, the best types of rim locks are used for doors in attics and basements, and for closet doors, but for all other doors, the medium-grade mortise locks are used. These locks are provided with cast- or wrought-bronze lock fronts, are made with from one to three lever tumblers, and have drop-forge steel cases. The locks are constructed with easy springs, which allow the latch bolt to retreat within the case on one light spring when the door is closed, and when the knob is turned, to operate the latch, both springs act jointly in order to overcome the friction of the knob and to throw the bolt back to central position. The mechanism of an easy-spring, mortise knob lock is illustrated in Fig. 39. [Pg 48]

Fig. 40

[Pg 49] In the group of locks embodying those of medium quality are included the three-bolt locks used for chamber and exterior doors, locks for communicating doors between chambers, and twin, or two-bolt, locks for twin bathroom or toilet-room doors, these being respectively illustrated in Fig. 40 (a), (b), and (c). All of these locks should be used with wrought- or cast-bronze trim, either plain or in design, and in finishes to suit. Locks for exterior doors, where security is important, should be selected with this object in view, and three-tumbler, or three-bolt, locks should be used.

37. High-Grade Locks.—There are a number of high-grade door locks and latches in the market for the equipment of first-class buildings, and frequently these locks are especially constructed to meet particular requirements. Among such locks are included, besides high-grade, three-tumbler locks, those that embody the cylinder principle and those that are equipped as master-key locks.

Fig. 41

The unit-cylinder lock, illustrated in Fig. 41, is made by P. & F. Corbin. This hardware specialty is a new departure in lock making. The mechanism of the lock is contracted into the smallest possible space, occupying only about 1½ in. × 3¼ in. Instead of being mortised into the stile of the door, as is usual with the mortise lock, a piece is cut entirely from the stile, as illustrated in Fig. 42. In order to prevent this operation from weakening the stile of the door, the unit-cylinder lock is provided with heavy escutcheon plates that are strongly ribbed on the back, so that when these plates are secured to the stile at the top and bottom, they supply the rigidity necessary to make up for the notching. As the name implies, these locks are made in [Pg 50] a unit, and the keyhole to the cylinder lock is located in the knob. The unit-cylinder lock is made in two styles—with dead-locking latch bolt and with additional dead bolt.

Fig. 42

38. High-Grade Interior Door Locks.—In Fig. 43 is shown a type of high-grade, mortise-locking latch for interior doors. These locks are of the heaviest construction, and are fitted with either brass or bronze fronts. The bolts are operated with two or more [Pg 51] tumblers constructed on an improved pattern, and are of fine workmanship. The trim for a lock of this character should be of the very best grade, with knobs of the screwless-spindle type, which will be explained later.

The escutcheons should be of the high-collar or the bracket-bearing type, and should conform to the character of the locks in quality and finish. On the most important work, it is always expedient and usually feasible to obtain expert advice from manufacturers or from dealers representing the manufacturer, whose intimate knowledge of the product will be of great assistance to the architect or owner in making suitable selections. The use of high-grade hardware requires a considerable expenditure, and the necessity for expert advice consequently becomes more imperative if the best results are to be obtained.

Fig. 43

39. Master-Key Locks.—The type of lock known as the master-key lock is generally used for public or office buildings, hotels, and occasionally in the better class of residence work. These locks can be grouped into two classes; namely, the Yale, or cylinder, and the lever-tumbler types, the class first mentioned being the most desirable.

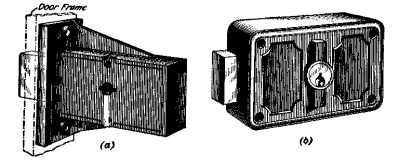

In the lever-tumbler type, illustrated in Fig. 39, the tumblers, or wards, are so arranged that each lock can be operated only by its particular key, the keys for all rooms being different and non-changeable; all of the locks, however, can be operated by a key [Pg 52] made for the purpose, termed a master key. Each lock of this type has two sets of tumblers; one set is operated by its individual key, and the other, being uniform in all locks of the series, is acted on by the master key. Such locks may be obtained either in the cheaper kind, with one tumbler and twelve changes, or in the most intricate styles of hotel locks, with five tumblers and 48,000 changes in one set, and all operated by one master key. The cylinder lock of this type is illustrated in Fig. 44, which shows a Yale & Towne, mortise, front-door lock.

Fig. 44

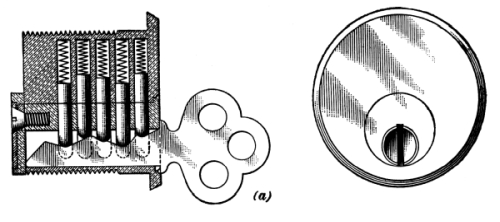

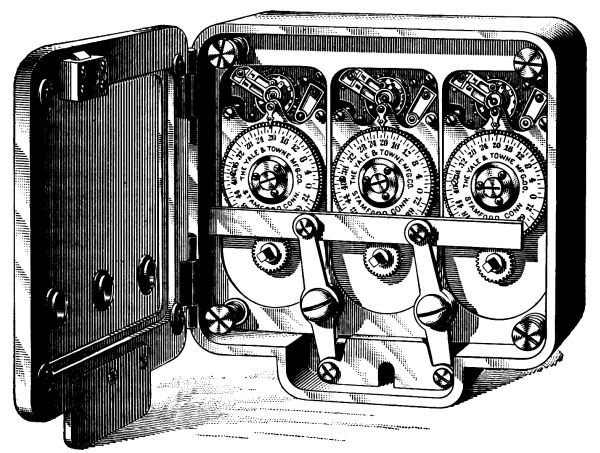

40. Details of the Yale Type of Master-Key Locks. The Yale type of cylinder lock, which is illustrated in Fig. 45 (a) and (b), is much preferred, on account of the great security it gives and the small key required by it. This lock is made in three systems; namely, the regular, the concentric, and the paracentric, or duplex.

In the regular system, one regular cylinder is controlled by the change and master keys, the pin tumblers being cut in two places, so that the change key brings one set of the abutting planes of the tumbler in alinement with the surface of the cylindrical plug. This plug is arranged so that a separate key is required to operate each lock, the other line of cleavage through the blocks being the same with all locks throughout the series, so that they may be opened with the same key. [Pg 53]

Fig. 45

Fig. 46

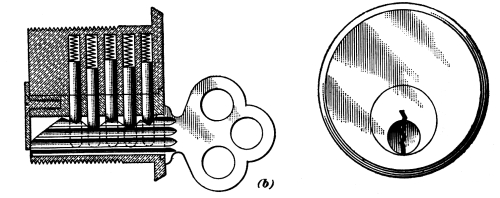

[Pg 54] The concentric cylindrical arrangement of this type of lock is shown in Fig. 46 (a) and (b). Here, there is a larger cylinder encircling the key plug. This is known as the master-ring, or larger, plug, and is indicated at a. When the change key is inserted in the key plug b, the lower series of breaks in the pins comes into alinement with the outer edge of the plug, as shown at (a), and allows it to revolve in the master ring, the cam on the inner side at c actuating the lock. When the master key is inserted, the upper series of breaks comes into alinement with the outer edge of the master ring, as shown at (b), allowing the plug and the ring to rotate together with the turning of the key, and thus to produce the same result as that caused by the operation of the change key.

Fig. 47

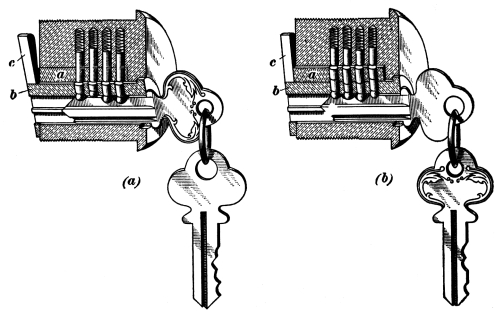

The paracentric system, sometimes called the duplex system, consists in having two separate cylinders to each lock, as illustrated in Fig. 47. One of these cylinders, generally the upper one, is operated by the change key, and the lower one, by the master [Pg 55] key. The interior construction of the lock is so devised that each key performs the necessary function of operating the same bolt, so that the individual lock may always be opened by the change key, and all locks of the series by the master key. This latter system of lock construction is more expensive than the one-cylinder type, but it possesses an advantage in that it provides greater security when a limited number of locks are grouped in one series.

41. Owners or officials of large office buildings and industrial works now avail themselves of the master-key system just explained. They are able to obtain mortise locks, rim locks, and padlocks, all arranged to operate with a master key, in one series. In fine residence work, this system is also adopted. Such a system of locking is easily recognized as convenient, especially where subordinates are held responsible for certain rooms or departments to which they, individually, have access, as all of the rooms or departments may be entered by the manager or superintendent by the aid of the master key.

A series of master-key locks may also be “submaster-keyed” by dividing it into subordinate groups. In such a case, each group is operated by a master key of its own, and all the subordinate groups are controlled by a grand master key. For example, a six-story office building could be furnished throughout with locks having non-changeable keys; the doors of each floor could be operated separately by a master key; and the doors of the entire building could be operated by a grand master key. The convenience of such a system is readily apparent in large buildings where each janitor is responsible for a certain floor, and where the head janitor, manager, or owner, has control of all the locks through the grand master key.

In some instances, for additional security and for special work, the corrugations in the keyway are changed in shape so that the manufacturers’ regular type of key will not enter the keyway, or plug, thus allowing no chance for the regular type of key to operate the lock. [Pg 56]

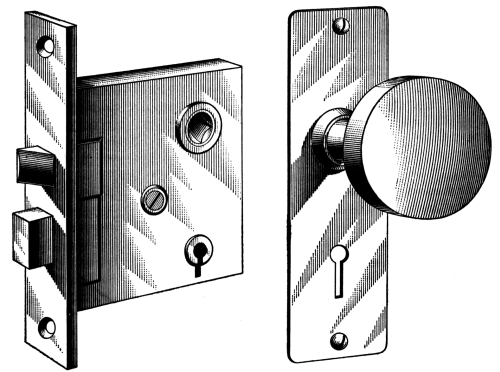

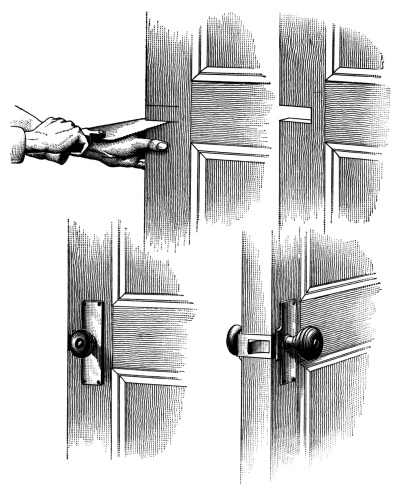

42. Locks for Residence Use.—The front-door lock is distinctly a lock having two bolts; namely, a dead bolt and a latch bolt. The latter is operated by the knob, and is so arranged that, by means of stop-work in the lock front, the outer knob may, at will, be set so as not to operate the latch, the latch bolt being operated only from the outside by a key.

Fig. 48

The cylinder type of front-door lock illustrated in Fig. 44 is the best lock for this purpose, as it provides the greatest security. This lock is operated by a convenient key of the Yale type, which throws both latch and dead bolt with one insertion into the cylinder.

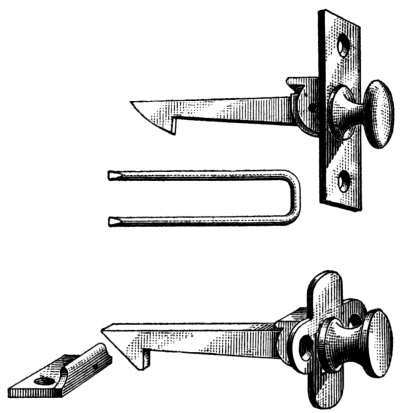

Three-tumbler, front-door locks and latches are to be had at a low cost, and are used in the cheaper class of dwellings. When the residence has an inner, or vestibule, door, a similar lock is used [Pg 57] without the dead bolt; this lock is termed a vestibule latch. In all cases the vestibule lock should “key-lock” with the front-door lock, so that one key will operate both. The other exterior doors of a residence should have either Yale locks master-keyed to the front door, for the better class of work, or locks of the 5-inch, three-bolt variety, that are furnished with an extra bolt in addition to the dead bolt, the third bolt being operated by a thumb knob on the inside. When a cheaper trim is wanted, a 4-inch, two-bolt lock, supplemented by a separate mortise or rim bolt, may be used.

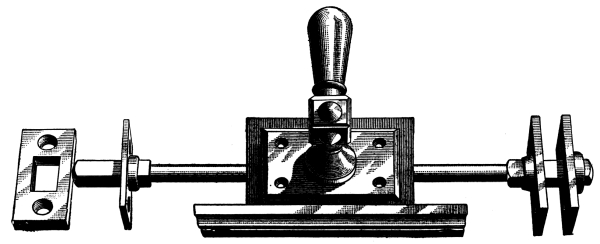

For the first- or parlor-floor folding doors, 4- or 4½-inch, two-bolt, mortise locks are ordinarily employed. Where the doors are sliding, a 5½-inch, sliding-door lock with dead bolt and pull, or handle, is provided. The pull, or handle, is operated, or thrown out, when needed by pushing a button, or stop, in the lock. This special type of sliding-door lock is illustrated in Fig. 48.

For bedroom doors, a lock similar to that used on the minor exterior doors is usually employed. The lock for these doors may be either a 5-inch, three-bolt lock, or a 4-inch, two-bolt lock supplemented with a mortise bolt. For communicating doors, it is best to use a three-bolt, knob lock, the latch bolt of which is operated by the knob from either side. Arranged above or below this latch bolt are two dead bolts, each being operated by its respective thumb piece on opposite sides of the door. Locks of this character are made for both swinging and sliding-doors.

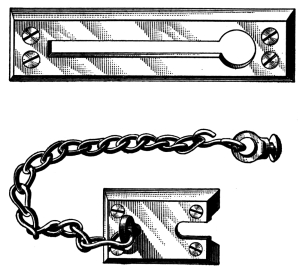

43. Locks for Twin-Closet and Other Interior Doors.—Twin, or double, doors are sometimes used between rooms in residences to deaden sound or to increase privacy. Such doors should be fitted with the same type of lock as other communicating doors, except that the lock should be provided with two bolts, the same as the lock used for bathroom doors. These locks are arranged with special trim on the abutting face of each door, this trim having only a slight projection, and knobs or lever handles projecting as little as possible, in order to avoid [Pg 58] interference on account of the limited space between the doors. Bathroom doors are best fitted with a thumb bolt, either combined with a lock or separate.

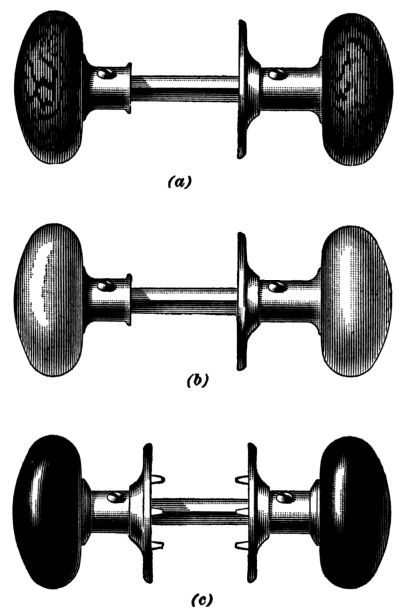

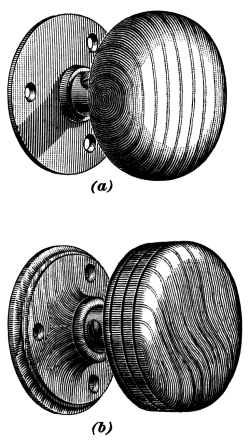

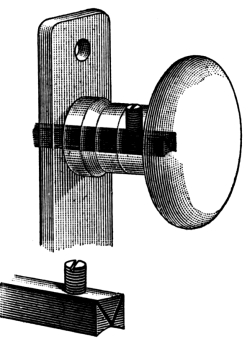

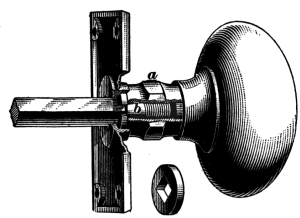

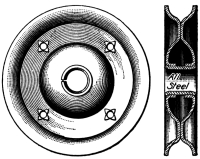

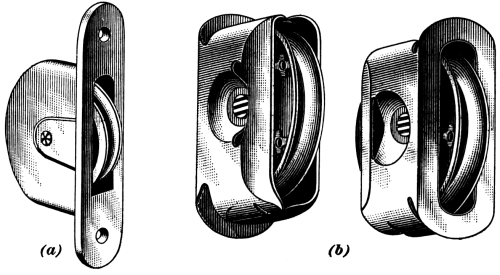

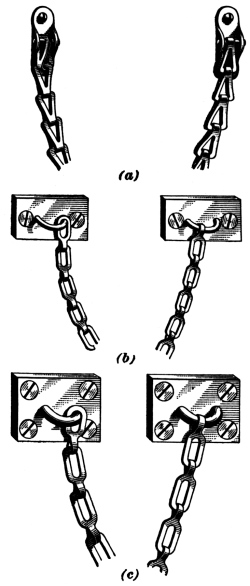

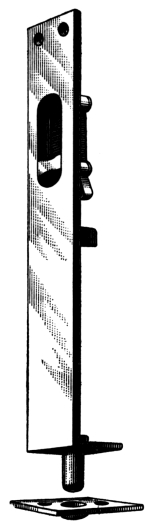

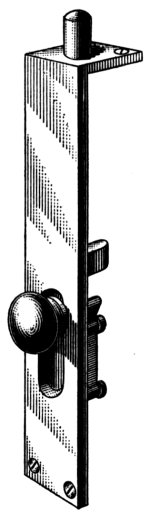

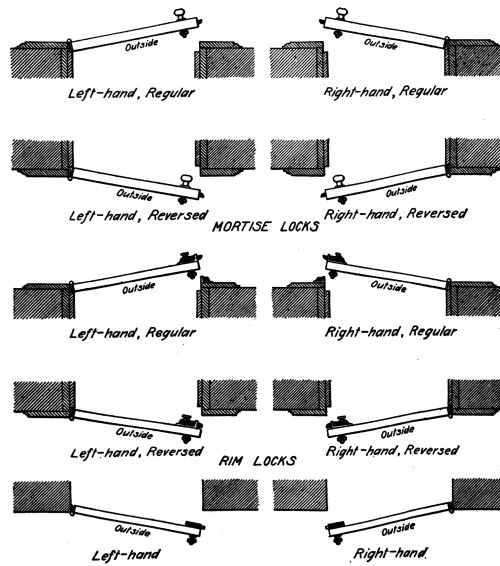

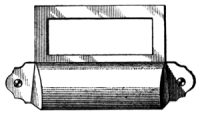

In fitting closet doors, it is best to use a two-bolt lock about 4 inches in size, with trim on both sides, so that the door may be operated from inside in case it is accidentally closed on a person in the closet. The possibility of this happening is slight, and usually a saving is effected by using a knob latch without a dead bolt and a pair of knobs with roses.